Meet the 72DL PLUS™ ultrasonic thickness gauge, a high-frequency and high-speed instrument capable of measuring ultra-thin and multilayer materials. This portable, easy-to-use device can handle a wide range of challenging thickness applications across industries, including automotive, aerospace, manufacturing, and power generation.

To help you get acquainted, this post will explore our top reasons to try the 72DL PLUS thickness gauge in your inspection workflow.

Precision Thickness Gauging: How It Started vs. How It’s Going

Higher frequencies enable you to measure thinner test material. In the past, most precision ultrasonic thickness gauges have been limited to a maximum of ~20 MHz frequency and to a minimum thickness capability of ~0.005 inches (0.125 mm).

Now with the 72DL PLUS gauge driving frequencies up to 125 MHz, you can make measurements well below the minimum thickness capability of traditional ultrasonic thickness gauges—as low as 0.001 inches (0.025 mm) or thinner.

The 72DL PLUS gauge is also fast (up to 2 kHz measurement speeds and a 60 Hz display update) to optimize your measurement workflow whether you’re using transducers with lower or higher frequencies.

These capabilities, along with its user-friendly features, make the 72DL PLUS gauge a powerful tool for a broad range of thickness applications using different frequencies. Here are eight reasons to try out the 72DL PLUS gauge today:

1. Measure thinner materials than ever before.

With the 72DL PLUS gauge, it is possible to measure single-layer material down to approximately 0.0005 in. (0.0127 mm), depending on the application. For instance, you can measure as low as 0.008 in. (0.20 mm) in single-layer steel and 0.0005 in. (0.0127 mm) in single-layer plastic. Note that the minimum thickness capability depends on the probe frequency, probe type, and test material.

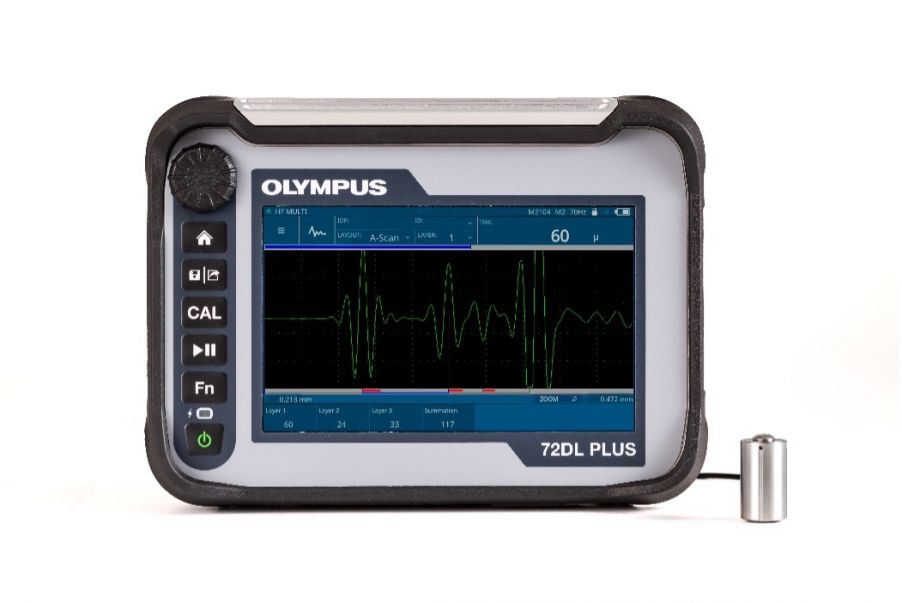

Thickness measurement of thin steel using the 72DL PLUS gauge with an M2104 transducer

2. Display the thickness of up to 6 layers at once.

With the Multilayer Measurement Software option, the 72DL PLUS gauge can measure a range of multilayer materials, including paint, plastics, metals, and coatings. It even has the unique ability to simultaneously display the thickness of up to six layers—two more layers than our 38DL PLUS™ gauge.

Multilayer measurement of paint thickness using the 72DL PLUS gauge with an M2104 transducer

3. Take thickness measurements at high speed.

Taking fast thickness measurements is important for time-sensitive applications such as turbine blade inspection. As a high-speed instrument with measurement speeds up to 2 kHz, the gauge increases throughput on the production floor.

Thickness measurement of a turbine blade using the 72DL PLUS gauge with an M208 transducer

4. Track thickness changes with 5 versatile measurement layouts.

While our handheld gauges provide a smaller screen, the 72DL PLUS gauge features a full color, 7 in. touch screen for greater visibility. Here you can access five measurement layouts—A-Scan, B-Scan, A/B-Scan, Trend, and Zoom—to fully visualize and track thickness changes.

Measurement layouts on the 72DL PLUS gauge make it easy to see thickness changes

5. Easily set up routine thickness measurements.

The gauge simplifies the device setup process for routine thickness measurements, eliminating the need to manually select and adjust settings before each inspection. Simply go to the My Applications menu on the startup screen, and the menu will walk you through each step to create an application. Alternatively, you can use the PC Interface Application to create applications from your desktop.

My Applications menu on the 72DL PLUS gauge

6. Easily collect, review, and manage thickness data.

Built-in data logging and onboard file management provide streamlined thickness data collection and processing, while the PC Interface Application includes intuitive tools to review and manage data for multiple devices and parts. Connected and cloud capable for Industry 4.0 practices, the gauge connects both wirelessly and through USB. It also integrates into the Olympus Scientific Cloud™ (OSC) where you can access free cloud-based features.

7. Greater uptime in industrial environments.

Like all our thickness gauges, the instrument is built to maximize uptime in tough industrial environments. It offers military-grade ruggedness (MIL-STD-810G) to protect against accidental drops or impacts and resistance against dust and moisture (designed to meet IP65). The gauge takes reliable measurements in both hot and cold climates with a wide operating temperature range (–10 °C to 50 °C or 14 °F to 122 °F).

8. Works with various transducers for versatile thickness applications.

The 72DL PLUS gauge is compatible with both standard frequency (0.2–30 MHz) and high-frequency (20–125 MHz) transducers. To support applications for ultra-thin material measurements, we’ve expanded our line of high-frequency transducers. The M2102 (75 MHz) and M2104 (125 MHz) are durable contact-style transducers for minimal frequency degradation and an optimal inspection range. Additional transducer solutions, including an improved high-frequency bubbler, are in development to support specialty customer needs.

Some of the available Olympus high-frequency transducers for ultra-thin material measurements. Left to right: B126 bubbler with an M2104 transducer, M2104 transducer, M2102 transducer, V215BB transducer, and M2104 transducer showing the fixed standoff discs.

72DL PLUS thickness gauges are available in Standard Frequency and High-Frequency models. To try out the 72DL PLUS gauge and compatible transducers, reach out to us for an in-person or virtual demo.

Related Content

Ultrasonic Thickness Gauge Tutorial

E-Book: Ultrasonic Transducers Technical Notes

Get In Touch