Automated Composite Part Inspection Systems

Overview

Composite Parts Manufacturing

Over the past decade, the aviation market has experienced a sustained period of significant growth. Global air traffic has risen at a steady rate, and commercial and military airplane manufacturers have undertaken several major programs (including the A350, A380, B787, and B777X). This development has been consistent despite ever increasing fuel prices and growing environmental concerns over emissions.

All of these factors have intensified the performance demands on aircraft manufacturers and their suppliers. High fuel prices and an increased focus on the environment have led manufacturers to develop new lightweight materials in order to build more efficient aircraft. Increased air traffic and the introduction of new airplane models puts pressure on the suppliers to maximize productivity, which they can achieve, in part, through faster inspection speeds.

High-speed inspection of composite parts is particularly difficult because of the complex geometries that are involved. To meet this challenge head-on, Olympus proposes its integrated instrumentation products, which have been especially designed for high-performance inspection systems.

Complex Geometry Inspection

Composite parts often feature diverse angles and surfaces that require the application of advanced inspection techniques. Olympus integrated instrumentation provides you with the necessary tools to meet these challenges.

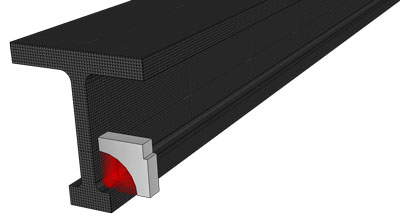

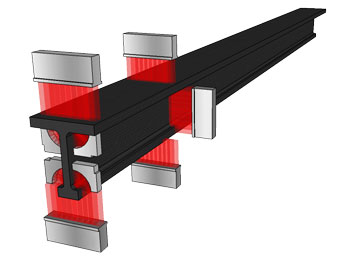

Corner InspectionCorner probes are specifically designed for the inspection of corner sections on composite parts. |  |

Full Volumetric CoverageUse multiple probes to ensure full part coverage in a single pass. Consult the Olympus probe portfolio to determine which probes are best suited for your application. |  |

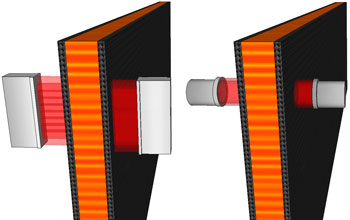

Honeycomb Structures InspectionUse pulse-echo and pitch-catch (through transmission) configurations on squirter systems to inspect parts containing honeycomb structures and/or with highly complex shapes. |  |

Solution

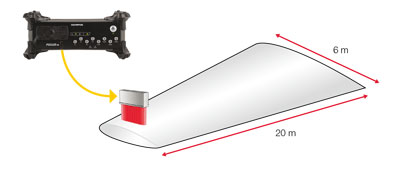

Unlimited Part Size Feature

The continuous inspection feature allows the inspection of very large parts without having to interrupt the inspection sequence. This feature enables data files to be continuously produced throughout the inspection, resulting in significant time savings.

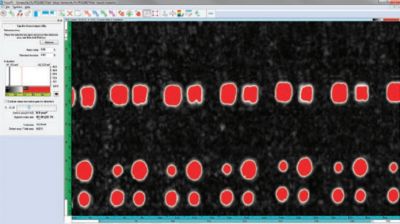

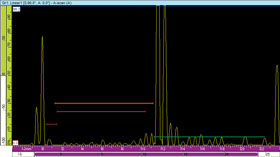

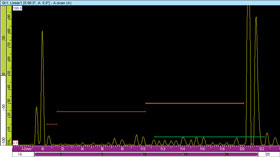

Signal-to-Noise Ratio (SNR) Analysis

Get precise SNR analysis using the composite analysis FocusPC tools.

Advanced Detection Capabilities

Multiple gates with advanced synchronization and presynchronization capabilities provide you with effective tools to deal with difficulties that are common with inspecting complex geometries, including parts with varying thicknesses.

|  |

|  |

Linked gates automatically adjust their position to account for geometric variation in the part.

Additional Features

- Precise delamination sizing.

- C-scan merging.

- Software C-scan.

- Firing sequencer for ghost-echo removal.

- Customizable layouts.

- Many more…

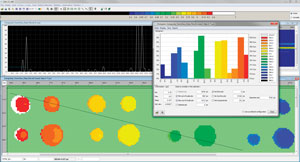

Industry Software Compatibility

FocusPC™ software development kits (SDK) are compatible with the following industry software:

- Ultis (EADS)

- SCAN (Boeing)

- CIVA (ExteNDE)

Screen courtesy of Airbus Group.

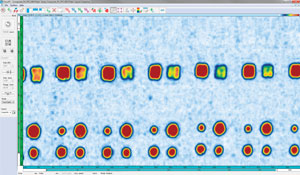

Fast Inspection Speed

The constant increase in the production rates of commercial and military aircraft means that quality control must also be done at higher speeds. The scalability and general specifications of Olympus integrated instrumentation will help you to address this industry challenge.

High Performance Unit

Use the FOCUS PX™ to build a fast and efficient inspection system by benefiting from the high end specifications of this powerful acquisition unit.

|  |

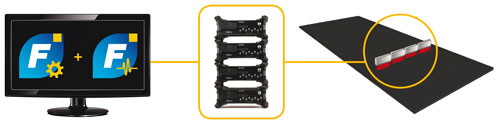

Scalability

Use up to four FOCUS PX acquisition units in parallel to minimize cycle time and optimize system performance.

Multiple-Probe Configurations

- Use multiple probes to ensure full part coverage in a single pass.

- Minimize cycle time while improving defect detection.

Powerful and Flexible Software

The FocusPC™ software was designed with powerful inspection features so that optimal inspection speeds can be reached. It can be easily integrated into typical industry software environments.

|  |

Full System Automation

Use the FocusPC Software Development Kits (SDK) to automate the workflow and improve system performance.

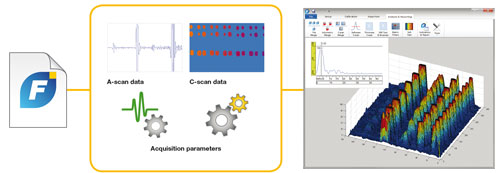

Customizable Data Analysis

Export raw inspection data to external data analysis software using the FocusPC SDK. Get more out of your inspection data by customizing the analytic process to meet your inspection requirements.