Veracity Technology Solutions has been providing nondestructive testing (NDT) services to the power generation, military, aviation, and aerospace markets since 2006. The company’s focus is on gas turbine inspections, which includes all aspects of the power generation equipment components.

They also have a training arm that provides NDT training and certification to military as well as civilian industries. Furthermore, many of Veracity’s current personnel are military veterans, and Veracity has been recognized by the HIRE Vets program for its commitment to veteran employment and professional development.

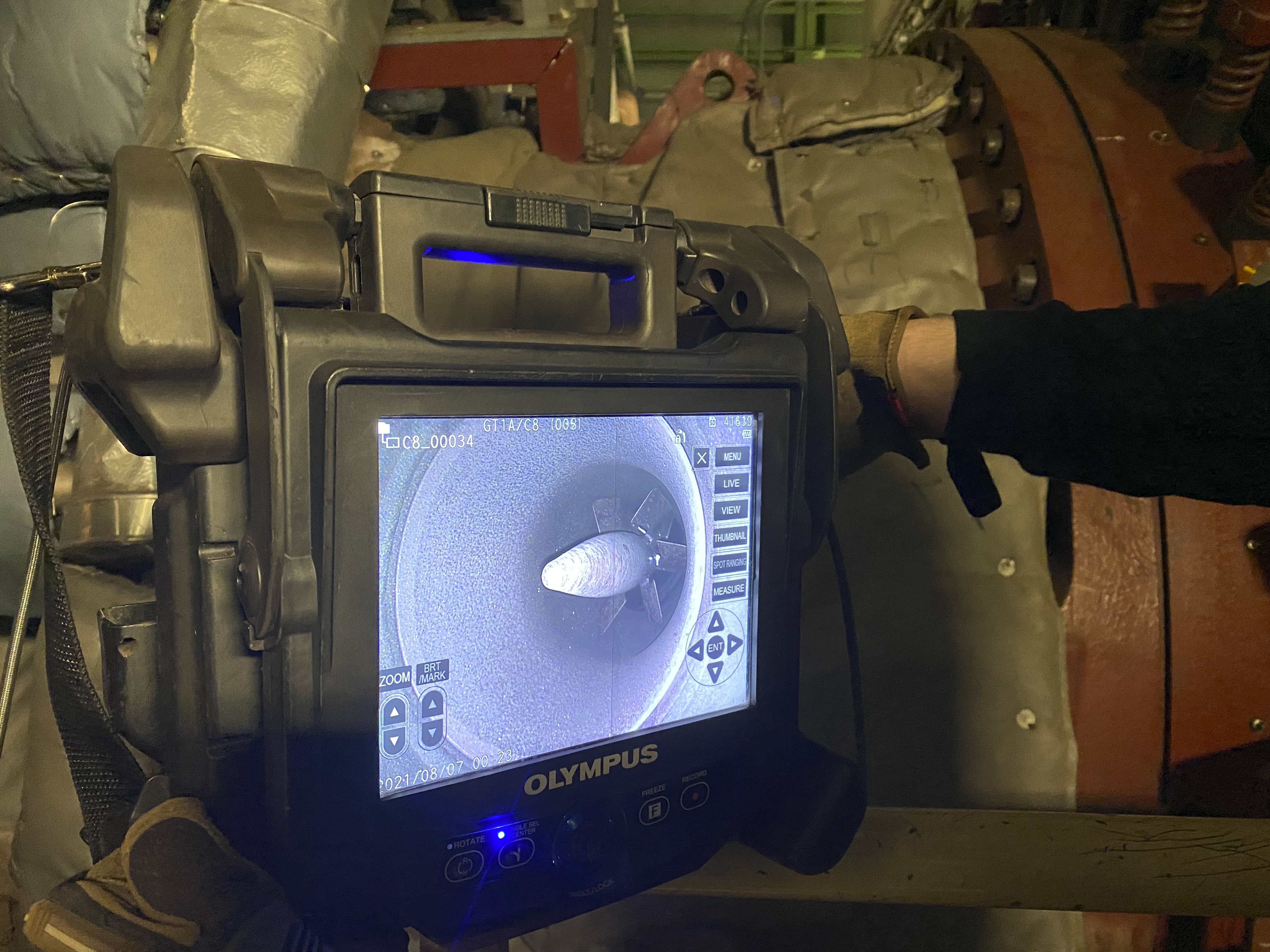

How Videoscopes and Borescopes Are Used in Gas Turbine Inspections

In the power generation market, one of the main services Veracity offers is remote visual inspection (RVI) of gas and steam turbines. A gas turbine inspection is generally scheduled based on the hours run and model. Additionally, forced or unplanned turnarounds or outages can occur where an emergency inspection is required to identify the cause.

“About 90% of our work with the IPLEX NX videoscope is on gas turbines.”

During a gas turbine inspection, a borescope technician takes a videoscope, such as an Olympus IPLEX™ videoscope, and inserts the distal tip of the insertion tube into the turbine engine. They navigate it to critical areas, such as the blades, vanes, and the combustion chamber, to view any damage or corrosion that may cause or has caused an issue.

Improving the Inspection Services Game for Veracity

Scott Kennedy, Veracity Technology Solutions’ VP of Business Development, has been in the industry for 29 years and was happy to sit down with Olympus and discuss how the IPLEX NX videoscope helped take Veracity’s inspections to the next level for its customers.

According to Scott, with the RVI equipment it used in the past, one of the more difficult tasks was providing cohesive and quick reports to power facility owners and operators. Additionally, its inspectors typically need to communicate directly with the owner/operator personnel who are there overseeing the inspection.

After purchasing the IPLEX NX videoscope, Scott says the company saw a rapid uptick in business because it helped improve the service Veracity offers. Compared with conventional videoscopes, the advanced features of the IPLEX NX videoscope helped increase efficiency both during the inspection and when reporting the results.

3 Main Benefits of the IPLEX NX Videoscope for Veracity

According to Scott, the reason that the IPLEX NX videoscope is a critical asset for performing gas turbine inspections boils down to these main features:

1. Screen Size and Image Quality

Both Veracity’s inspection technicians and other personnel on the job site appreciate the optimal viewing provided by the IPLEX NX videoscope’s large screen and bright, vibrant imaging capabilities. Scott says that this aspect has come in handy numerous times. He can stand on a turbine deck and pivot the screen to a project manager who is several feet away, and they can easily see and understand what is shown onscreen.

2. Ease of Use and Easy Measurements

Taking measurements is easy on the large touch screen, making the task more efficient for the inspection technician. Consequently, reporting back to the on-site project manager is also much faster. Features such as the IPLEX NX videoscope’s spot-focusing and spot-ranging have also helped speed up the average time it takes an inspector to take a measurement.

3. Better, More Comprehensive Reporting

At the end of every inspection, a report is prepared with any findings and recommendations. The image quality and the ability to easily navigate folders and pull the images to include has helped improve the end-report product Veracity provides its customers.

“The equipment speaks for itself, and I know our customers appreciate the benefits it provides them.”

To sum up, Scott says, “The equipment speaks for itself, and I know our customers appreciate the benefits it provides them. For us, the IPLEX NX videoscope is a powerful instrument for our certified borescope inspectors but is still easy enough for a plant technician to learn to use for a simple component inspection check. It’s been a great tool to increase our business and provide a better service to our customers.”

Related Content

How to Confirm Videoscope Measurement Points with Confidence

3 Methods to Inspect Heat Exchanger Tubes

Three Essential Tips to Extend the Life of Your Videoscope

Get In Touch