Overview

39DL PLUS™ Ultrasonic Thickness GaugeFaster Thickness ResultsStreamline your ultrasonic thickness inspection process with one fast, connected, and reliable handheld gauge. The 39DL PLUS™ gauge works as a precision or corrosion thickness gauge for demanding applications. With world-class ultrasonic capability, fast scanning speeds up to a 60 Hz update rate, and fully integrated wireless connectivity, our flagship handheld thickness gauge delivers results you can trust in a seamless workflow.

*Wi-Fi® and Bluetooth® are pending certification in some regions. Contact your local Evident representative for details on their availability.

|

| Affordable Part ScanningWith breakthrough scanning speeds, the 39DL PLUS instrument offers an industry-leading* 60 Hz update rate for handheld thickness gauges.

*As of June 2024. |

One Thickness Gauge for Multiple ApplicationsTake advantage of powerful measurement features and a suite of application-specific software options for your current and future requirements.

|

Key Benefits

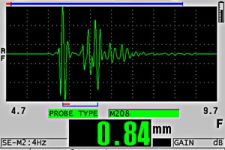

Trusted Ultrasonic TechnologyThe 39DL PLUS™ gauge builds on proven performance. Confidently perform your work with industry standard technology for ultrasonic thickness testing.

|

| Built to Last in Any EnvironmentYour thickness gauge needs to keep working despite shocks, drops, and rough handling, and the 39DL PLUS instrument is up to the challenge.

|

Easy to Carry, Easy to UseDesigned with the operator in mind, the 39DL PLUS handheld gauge is comfortable to carry and use in the field or on the production floor.

|

|

Workflow

Save Time with a Digital Inspection WorkflowIntegrated Wi-Fi® and Bluetooth® capabilities on the 39DL PLUS™ thickness gauge enable a seamless inspection workflow for Industry 4.0.

| |

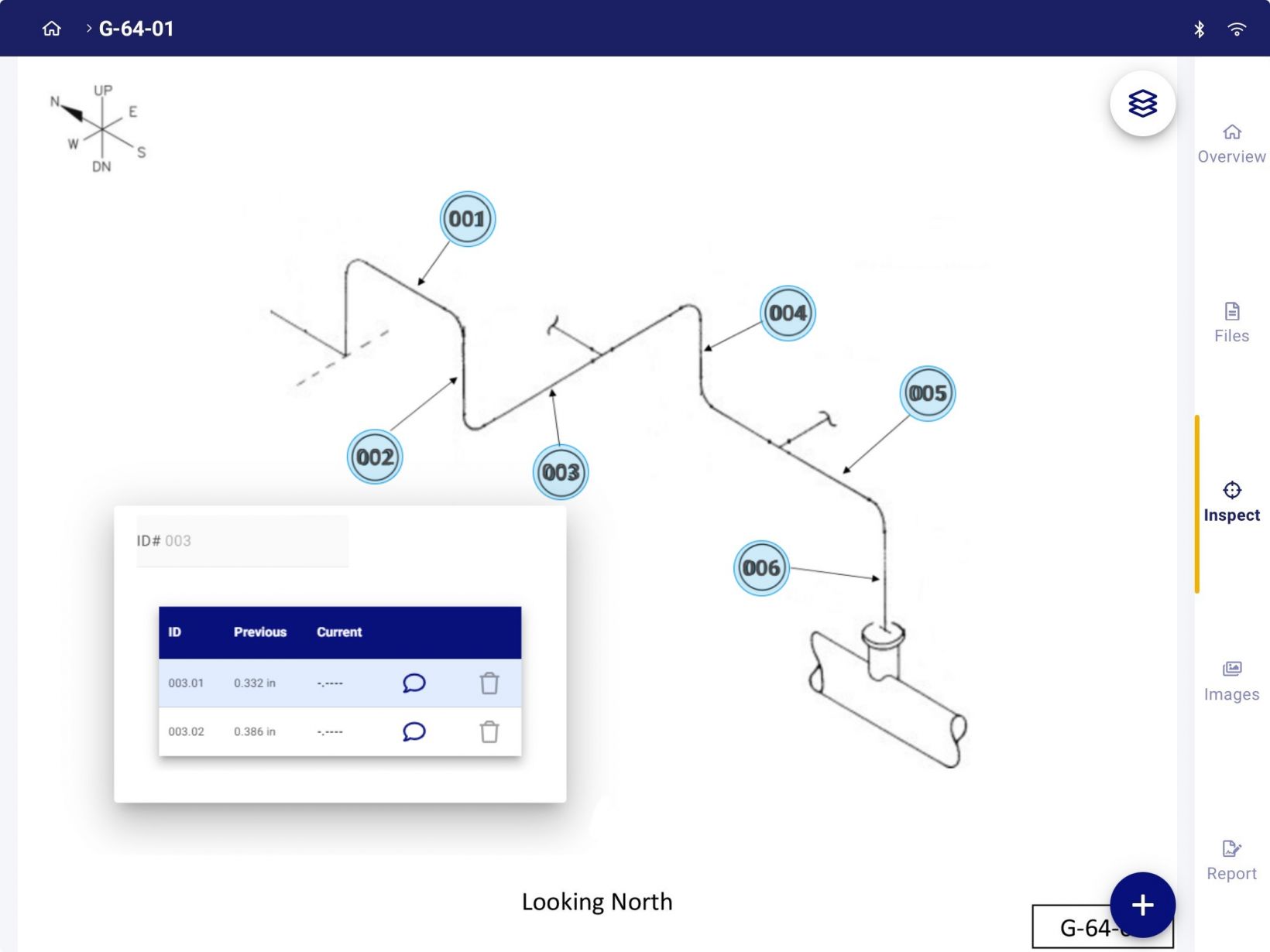

Powerful Workflow Management ToolsThe Inspection Project Manager (IPM) is a cloud-based web and mobile app offering a digital inspection workflow that improves efficiency and data integrity.

| |

Send Thickness Data to Your Mobile Phone or TabletUse the Link Plus iOS app and Bluetooth® to send thickness data to your phone or tablet.

| |

Easily Populate Your Thickness Data into Data Entry ProgramsUse the optional Link-Wedge software and Bluetooth® to send data from your gauge to an active Windows software application. The software can populate data into almost any Windows-based data entry program. | |

Remote Control and IntegrationThe 39DL PLUS gauge offers the potential for remote control and integration, enabling convenient control of the gauge from a distance in innovative applications. To learn more about these capabilities, reach out to your local Evident sales representative. |

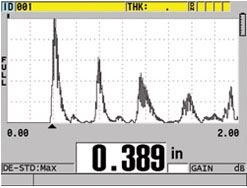

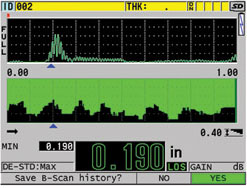

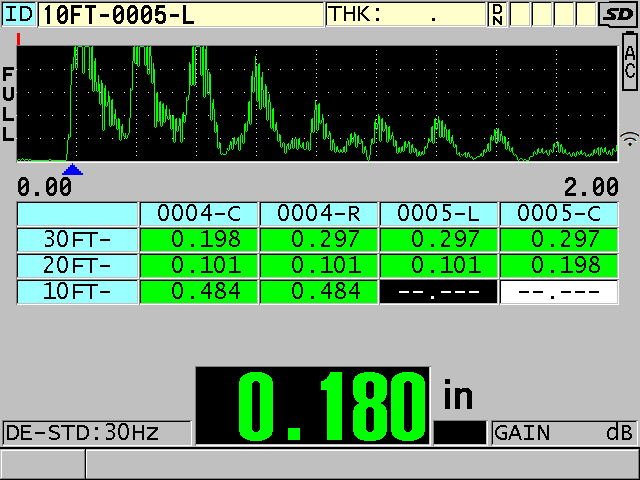

| Confidence in Your Thickness DataBuilt-In Data LoggerImprove productivity and data traceability with the full-featured, built-in data logger on the 39DL PLUS gauge. The bidirectional alphanumeric data logger is designed to easily collect and transfer thickness readings and waveform data. | |

| ||

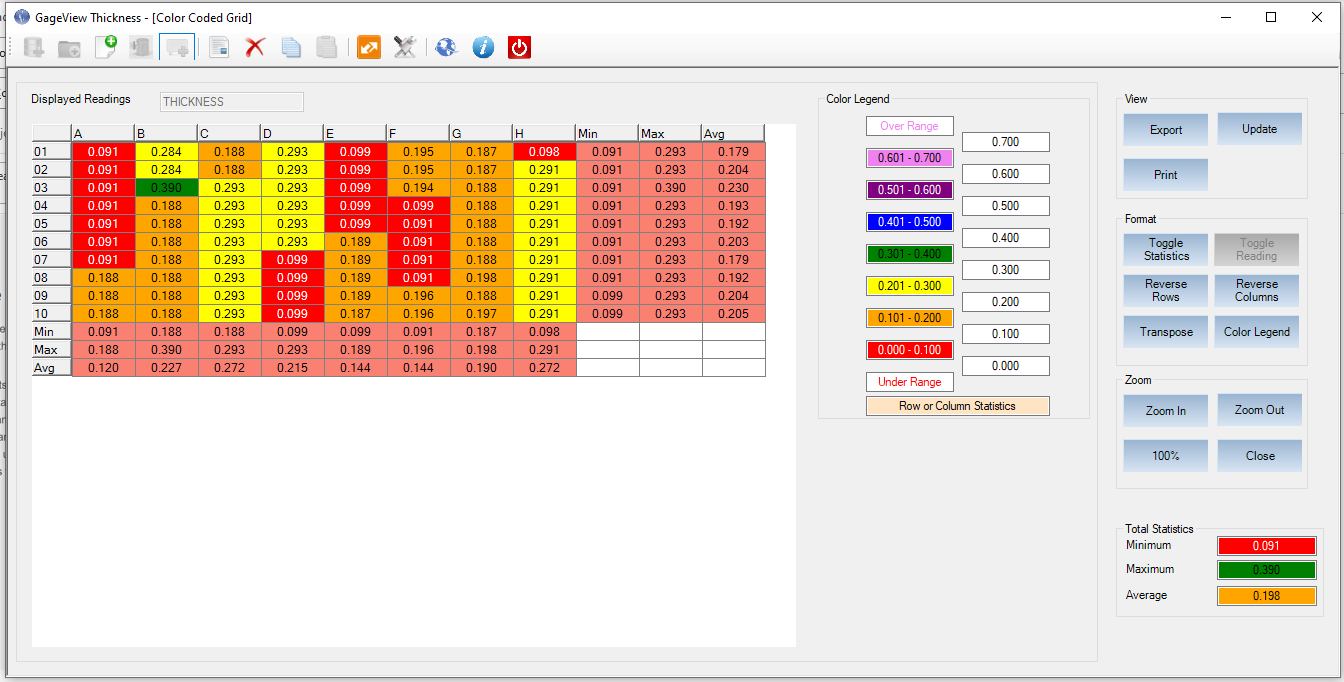

PC SoftwareThe GageView™ interface program, a Windows-based application, collects, creates, prints, and manages data from the 39DL PLUS gauge. The software communicates with the gauge using the USB and RS-232 ports, and it can read and write to a microSD memory card.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by Evident Corporation is under license. |

Applications

The 39DL PLUS™ instrument works as a precision or corrosion thickness gauge in a variety of inspections. Explore the applications below to discover common inspections, related software features, and a full line of compatible transducers. | |

|

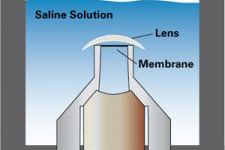

Transducers for Precision Thickness GaugesEvident offers a complete selection of single-element transducers, cables, couplants, calibration test blocks, and accessories to meet a wide variety of precision thickness gauging applications. |

|

Transducers for Corrosion Thickness GaugesEvident offers a complete selection of dual element transducers and cables to meet a wide variety of corrosion thickness gauging applications. |

Specifications

39DL PLUS™ Specifications |

| Measurements > Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

|---|---|

| Measurements > THRU-COAT™ measurement | Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM and D7908 transducers) |

| Measurements > Thru-Paint Echo-to-Echo | Time interval between two successive back-wall echoes to eliminate paint or coating thickness |

| Measurements > Single element transducer measurement modes | Mode 1: Time interval between the excitation pulse and the first back-wall echo

Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers) Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers) Oxide: optional Multilayer mode: optional |

| Measurements > Thickness range | 0.08 mm to 635 mm (0.003 in. to 25 in.) depending on material, transducer surface conditions, temperature, and selected configuration |

| Measurements > Material velocity range | 0.508 mm/μs to 13.998 mm/μs (0.02 in./μs to 0.551 in./μs) |

| Measurements > Resolution (selectable) | Low: 0.1 mm (0.01 in.)

Standard: 0.01 mm (0.001 in.) High Resolution (optional): 0.001 mm (0.0001 in.) |

| Measurements > Transducer frequency range | Standard: 2.0 MHz to 30 MHz (-3 dB)

High Penetration (optional): 0.50 MHz to 30 MHz (-3 dB) |

| General > Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| General > Keypad | Sealed, color-coded keypad with tactile and audible feedback |

| General > Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67. |

| General > Dimensions (W x H x D) | Overall: 125 mm × 211 mm × 46 mm (4.92 in. × 8.31 in. × 1.82 in.) |

| General > Weight | 0.83 kg (1.83 lb) |

| General > Power supply | AC/DC adapter, 24 V; lithium-ion battery 23.760 Wh; or 4 AA auxiliary batteries |

| General > Battery life, lithium-ion |

Operating time: typically 8 hours

Fast charge: 2 to 3 hours |

| General > Standards | Designed for EN15317 |

| General > Explosive Atmosphere | Testing using MIL-STD-810H, Section 511.7, Procedure I |

| Display > Color transflective VGA display | Liquid crystal display, display area 56.16 mm x 74.88 mm (2.2 in. x 2.95 in.) |

| Display > Rectification | Full wave, RF, half-wave positive, or half-wave negative |

| Inputs/Outputs > USB | USB 3.0 |

| Inputs/Outputs > RS-232 | Yes |

| Inputs/Outputs > Memory card | Maximum capacity: 32 GB external microSD memory card |

| Inputs/Outputs > Video output | VGA output standard |

| Wireless Communication > Wi-Fi® | Integrated |

| Wireless Communication > Bluetooth® | Integrated |

| Internal Data logger > Data logger | The 39DL PLUS identifies, stores, recalls, clears, and transmits thickness readings, waveform images, and gauge configuration information through the standard RS-232 serial port or USB port |

| Internal Data logger > Capacity | 792,832 thickness measurements or 20,000 waveforms with thickness measurements |

| Internal Data logger > File names, IDs, and comments | 32-character file names and 20-character alphanumeric location codes with four comments per location |

| Internal Data logger > File structures | Nine standard or custom application-specific file structures |

| Internal Data logger > Reports | On-gauge reporting of summary with statistics, Min./Max. with locations, Min. review, file comparison, and alarm report |

Standard Package39DL PLUS digital ultrasonic thickness gauge, AC or battery, 50 Hz to 60 Hz. Kits available with standard dual element transducers.*

Measurement features: THRU-COAT, Thru-Paint Echo-to-Echo, EMAT compatibility, Min./Max. mode, two alarm modes, differential mode, B-scan, Application Auto-Recall, temperature compensation, Average/Min. mode *In the EMEA region, transducers are not included and must be purchased separately. Software Options39DLP-OXIDE (Q1470008): Code-activated Internal Oxide measurement software

Optional Accessories1/2XA/E110 (U8767104): Filter adapter for E110-SB EMAT transducer

|