Flaw Detectors / Phased Array Flaw Detectors

Our full range of portable ultrasonic and phased array flaw detectors provide outstanding capabilities for locating subsurface defects. Using ultrasonic soundwaves, these advanced units can be used to locate and size hidden cracks, voids, disbonds, and similar discontinuities in a wide range of materials. Olympus offers a variety of devices for enhanced flaw detector inspection: the EPOCH™ 650 flaw detector is designed for excellent inspection performance and usability, while the EPOCH 6LT lightweight flaw detector is optimized for one-handed operation in rope access and high-portability applications. On this page, you will also find video tutorials for our flaw detectors that can help you unlock the capabilities to perform advanced and efficient ultrasonic testing. | EPOCH 650 Product Introduction Cast Components in the Foundry Industry |

Eddy Current and Ultrasonic Flaw Detectors

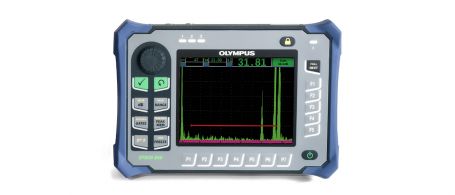

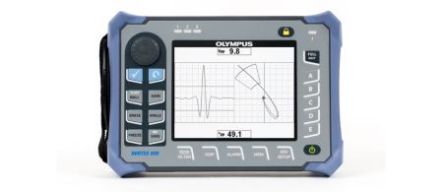

Ultrasonic Flaw Detectors

Our range of ultrasonic (UT) flaw detectors offer leading-edge features and capabilities for locating discontinuities and other flaws.

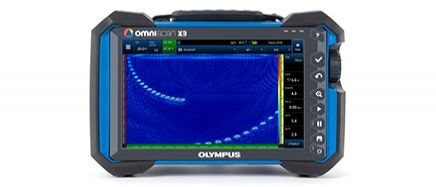

Phased Array Flaw Detectors

Olympus phased array (PA) instruments produce accurate, detailed cross-sectional pictures of internal structures at fast inspection speeds. Units with TFM/FMC are available for advanced applications.

Eddy Current Flaw Detectors

Advanced eddy current (EC) flaw detectors are used to inspect metallic parts and perform highly reliable flaw detection of surface and near-surface defects.

Eddy Current Array Flaw Detectors

Eddy current array (ECA) instruments provide the ability to electronically drive and read eddy current sensors positioned side by side in the same probe assembly.

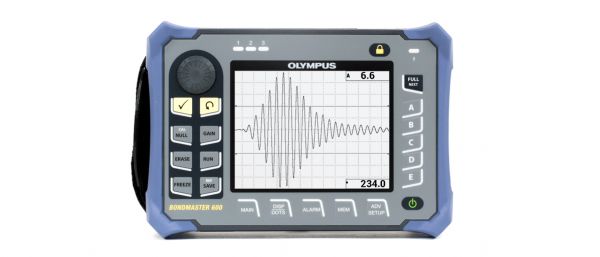

Bond Testing

Our complete line of bond testing (BT) flaw detectors provides outstanding capabilities for the location of discontinuities and other flaws in composite structures. We offer a wide range of measurement features and application-specific options for flaw detection.

Probes and Transducers

Probes and transducers help you meet demanding inspection requirements with high-quality probes and transducers in various frequencies, configurations, connector styles, and cable types.FAQ

What is ultrasonic nondestructive testing?

Ultrasonic nondestructive testing (NDT) is a method used to detect the thickness or internal structure of different materials. It enables you to identify flaws in the material such as subsurface defects. Ultrasonic testing works by sending high-frequency sound waves through a material and analyzing the echoes that come back. By analyzing these reflections, you can test the thickness of the material or identify if there is any internal damage, such as cracks or defects.

Flaw Detector Resource Videos

EPOCH 6LT Basic Operation OverviewThis video provides a basic overview of the EPOCH 6LT functions. It will walk you through all the flaw detector’s capabilities and how to put them to use. | |

Rail Inspection: Using NDT Ultrasonic TechnologiesThis video explains how to use the EPOCH 650 ultrasonic flaw detector to find discontinuities and other flaws in rails. | |

Cast Components in the Foundry IndustryLearn how to use the EPOCH 650 ultrasonic flaw detector for porosity and void detection in cast parts, as well as graphite nodularity testing in cast iron. |