USPM-RU-W

Overview

Olympus' USPM-RU-W Enables Accurate and Fast Measurements of Curves Surfaces and Minute Areas

Olympus' USPM-RU-W NIR Micro-Spectrophotometer performs fast, accurate spectrometry across a wide range of wavelengths of visible light to near-infrared.The ability to easily measure reflectivity of extremely small areas or curved surfaces that cannot be measured using ordinary spectrophotometers, makes the USPM-RU-W optimally suited for analyzing optical elements or minute electronics parts.

- Near-Infrared Micro-Spectrophotometer

- Fast Measurements of Curves Surfaces and Minute Areas

- Diverse application

Near-Infrared Micro-Spectrophotometer

■ Reflectivity, Film thickness, Object color, and transmittance measured in seconds

■ Wide range of wavelength from 380 to 1050 nm

■ Measures reflectivity on curved surface without contact

Measure Reflectivity

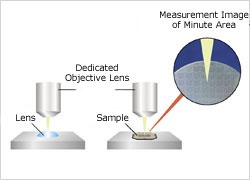

Measure the reflectivity of a minute area with a diameter ranging from 17 to 70 um

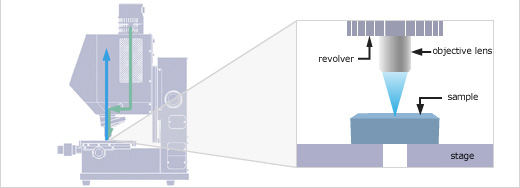

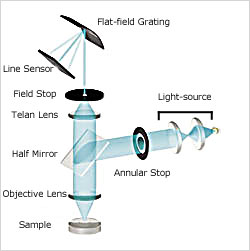

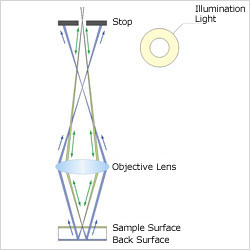

Optical Path of Reflectivity Measurement | |

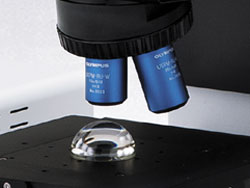

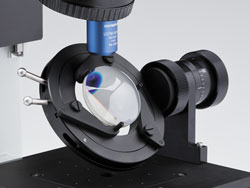

Example of reflectivity measurement : lens |  Example of reflectivity measurement : lens curvature |

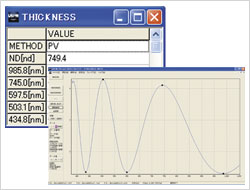

Film Thickness Measurement Screen-shot | Measure Film ThicknessUse reflectivity data to measure the thickness of single-layer or multi-layer films of approximately 50 nm to 10 μm. |

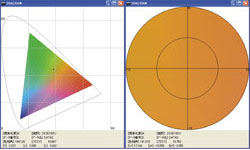

Object Color Measurement Screen-shot | Measure Object ColorDisplay an XY chromaticity diagram, an L*a*b* chromaticity diagram, and their related numeric values based on reflectivity data. |

Measure Transmission Levels (Available as an option)

Measure the transmittance of a plane sample by transmitting 2 mm parallel beams of lights through the sample to the spectrophotometry acceptance elements.

Optical Path of Transmittance Measurement |

Measure Reflectivity at an Incidence Angle of 45 Degrees(Available as an option)

Measure the reflectivity at an incidence angle of 45 degrees by reflecting 2 mm parallel beams of lights to the spectrophotometry acceptance elements.

Optical Path of 45-degree Reflectivity Measurement |

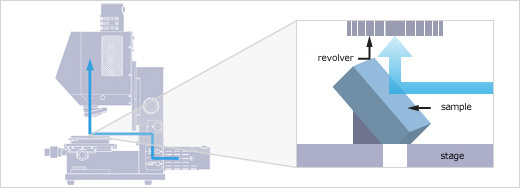

Fast Measurements of Curves Surfaces and Minute Areas

Optical system image | Provides High-speed MeasurementQuick, high repeatability measurements can be achieved in seconds using a flat field grating, line sensor and high-speed spectrophotometry. |

Image of reflectivity measurment | Optimally Suited for Reflectivity Measurement of Extremely Small Parts and LensesOlympus has designed a new dedicated objective lens that provides non-contact measurements across an area of 17 to 70 μm diameters. The new lens provides high repeatability on even curved surfaces or minute electronic parts. |

Principle of backside reflection elimination | Anti-reflection Processing is Not Required on the Back of the SampleAccurate measurement of surface reflectivity can be performed without the costly steps needed to prevent rear surface reflection. Rear surface-reflected light is reduced by means of special optics that block all out-of-focus light reflection similar to a confocal system. Whether your optical component is spherical,aspherical or flat, the USPM-RU-W does not require sample preparation through anti-reflection treatments. |

Available Film Thickness Measurement Methods

The single-layer or multi-layer film thickness can be analyzed according to the measured spectral reflectivity data. You can select the optimum measurement method for the application.

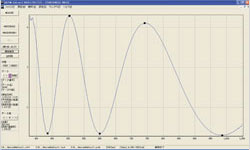

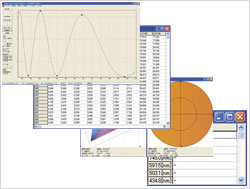

Peak valley film thickness analysis result | Peak-valley MethodThis method is used to calculate film thickness based on the periods between the peaks and valleys of the measured spectral reflectivity value, and is effective for measuring single-layer film. No complicated settings are required, so measuring film thickness is easy. |

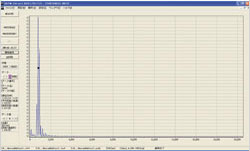

Fourier transform film thickness analysis result | Fourier Transform MethodThis method is used to calculate film thickness based on the periods between measured spectral reflectivity values, and is effective for measuring single-layer and multilayer films. The Fourier transform method eliminates noise, thus making analysis possible when it is difficult to detect peak and valley values. |

Curve fitting film thickness analysis result | Curve Fit MethodThis method is used to calculate film thickness by estimating which structure has the smallest difference between the measured spectral reflectivity and the calculated reflectivity for that structure, and is effective for measuring single-layer and multilayer films. The curve fit method also makes it possible to analyze thin film in which peak and valley values are not apparent. |

Diverse application

Satisfies Diverse Measurement Needs at High Speed and With High Precision

| Evaluation of Lens Coating for reflectivity,color and film thickness.

Mobile Phone Camera Lenses

|

| Examining the Reflectivity and Film Thickness of Minute Electronic Parts.

LED Packages

|

| Reflectivity, Film Thickness and Transmittance measurment of Planar Optical Elements.

LCD color filters

|

| Optical Elements Reflectivity at an Incident Angle of 45 Degrees.

Prisms

|

Specifications

USPM-RU-W NIR Micro-Spectrophotometer:Specifications

| Reflectivity measurement | Transmittance Measurement*1 | Reflectivity Measurement for 45-Degrees*1 | |||

| Name | NIR Micro-Spectrophotometer |

Transmittance measurement set for

NIR Micro-Spectrophotometer |

45-degree reflectance measurement set for

NIR Micro-Spectrophotometer | ||

| Model | USPM-RU-W | ||||

| Measured wavelength | 380 to 1050 nm | ||||

| Measurement method | Compared with a reference sample for measurement | Transmissivity is measured with 100% as standard | Compared with a reference sample for measurement | ||

| Measurement range | See the specifications of the objective lens below | Approx. 2.0 mm in diameter | |||

| Measurement repeatability(3σ) *2 | Reflectivity measurement | During use of 10x and 20x objective lenses |

±0.02% or less (430 to 1010 nm)

±0.2% or less (Except as described above) |

±0.3% or less (430 to 1010 nm)

±1.0% or less (Except as described above) | |

| During use of a 40x objective lens |

±0.05% or less (430 to 950 nm)

±0.5% or less (Except as described above) | ||||

| Film thickness measurement | ±1% | - | |||

| Wavelength display resolution | 1nm | ||||

| Lighting accessory | Dedicated halogen light source, JC12V 55W (Average life: 700 hours) | ||||

| Shift stage |

Loading surface size: 200 (W) x 200 (D) mm

With stand load: 3 kg Operating range: (XY) ±40 mm, (Z) 125 mm | ||||

| Tilt stage | - |

Loading surface size: 140 (W) x 140 (D) mm

Withstand load: 1 kg Operating range: (XT) ±1*, (YT) ±1* | |||

| Weight | Main body: Approx. 26 kg (not including PC) | Main body: Approx. 31 kg (not including PC)*3 | |||

| Control power box: Approx. 6.7 kg | |||||

| Dimensions | Main body: 360 (W) x 446 (D) x 606 (H) mm | Main body: 360 (W) x 631 (D) x 606 (H) mm | |||

| Control power box: 250 (W) x 270 (D) x 125 (H) mm (Protruding parts are not included) | |||||

| Power specifications | Input specifications: AC 100-240V (110V) 50/60Hz | ||||

| Operating environment |

Horizontal place not subject to vibration

Temperature: 15 ºC to 30 ºC Humidity: 15% to 60% RH (Free from dew condensation) | ||||

*1 Optional unit *2 Measured under the measurement conditions of our company. *3 The total weight of both the transmissivity measurement set and 45-degrees reflectivity measurement set installed is approx. 33 kg.

Objective lens

| Model | USPM-OBL10X | USPM-OBL20X | USPM-OBL40X |

| Magnification | 10x | 20x | 40x |

| Measurement NA*4 | 0.12 | 0.24 | 0.24 |

| Measurement range*5 | 70μm | 35μm | 17.5μm |

| Operating distance | 14.3mm | 4.2mm | 2.2mm |

| Operating distance | ±5 mm or more | ±1 mm or more | ±1 mm or more |

*4 It differs from objective lens' NA.

*5 Spot diameter

Software

Spectral Analysis Software with an Easy-to-use User Interface

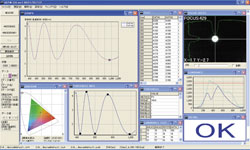

Example of GUI layout | Easy-to-understand DisplayChange the layout and position, size, and visibility of each window according to the measurement purpose and user needs. |

Reflectivity/transmittance graph, reflectivity/transmittance text, XY/L*a*b* chromaticity diagram | Diverse Measurement ResultsSpectral reflectivity/transmissivity graphs and text, color measurement (XY and L*a*b* chromaticity diagrams), and film thickness measurement values can be displayed on one screen for easy understanding. |

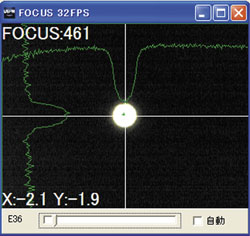

Easy Position Adjustment and Focus Adjustment

Positioning the measuring point is easy by using a focusing window for Z axis alignment and centering (CT) window for X and Y axis alignment.

Focus |  Position Adjustment |

Work setting, layer setting, graph setting, parameter setting | Flexibility for Any ApplicationThe USPM-RU-W software can be configured to achieve optimum performance for your specific sample. |

Example of reflectivity measurement with Tolerance setting function | Tolerance setting function of automatic pass / fail determination.System can be configured to provide good / no good designations automatically. |