Phased Array

Evident phased array instruments provide precise measurement with the most reliable results. Our range of phased array devices produce accurate, detailed cross-sectional pictures of internal structures at fast inspection speeds. Here you can find phased array equipment and instruments including flaw detectors, scalable acquisition units, and phased array inspection software to work alongside your phased array device. These powerful tools allow you to complete even the most demanding inspections with confidence, offering precise data acquisition, visualization and analysis of ultrasonic signals. Our phased array equipment and phased array software solutions are fully integrated, with fast calibration and streamlined user interfaces so you can complete your setup and inspection in minimal time. |

Phased Array Devices

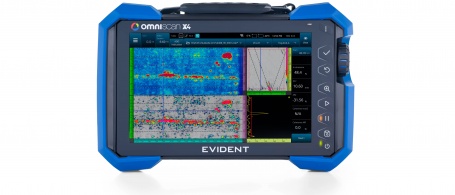

OmniScan X4

Detect and interpret challenging flaws and identify damage earlier with the powerful, yet portable OmniScan™ X4 multitechnology flaw detector. Exploit its versatile PA, faster TFM, innovative PCI, and efficient twin TFM/PCI to perform rapid and reliable inspections of welds and components.

OmniScan X3 Series

FOCUS PX Acquisition Unit | FocusPC™ Software & SDK

The scalable FOCUS PX acquisition unit and FocusPC software incorporate the latest phased array (PA) and conventional UT technologies for easy integration into automated and semiautomated systems. This inspection solution enables you to generate and save C-scan and A-scan raw data for applications where the verdict is based on post-inspection data analysis. This includes applications in industries such as aerospace (composite laminate), power generation (wind blade), transportation (train wheels), metal (forged parts), and more.

OmniScan SX

Phased Array Machine FAQs

What are phased arrays used for?

Phased array systems can be employed in almost any test where conventional ultrasonic flaw detectors have traditionally been used. They are used across a range of industries, including aerospace, power generation, petrochemical, metal billet and tubular goods supply, pipeline construction and maintenance, structural metals, and general manufacturing. Phased arrays are often used in weld inspections, crack detection, and corrosion mapping.

What are the advantages of phased array systems?

Compared with traditional ultrasonic testing systems, which use single- or dual-element transducers, phased array inspection systems use multiple elements. The multielement configuration enables the user to steer, focus, and scan the beam with a single probe assembly. This makes mapping components with odd angles and complex geometries much easier and more accurate than with traditional ultrasonic equipment.

Phased Array Instrument Resources

FMC/TFM Basic PrinciplesLearn more about FMC/TFM in this basic principles video and how they differ from conventional phased array. |