Olympus Ultrasonic Transducers

Olympus ultrasonic probes and transducers are used for flaw detection, thickness gauging, materials research, and medical diagnostics. Our more than 4,000 transducer types include contact, dual element, shear wave, delay line, and immersion. If you don’t find what you’re looking for in our transducer catalog, we can create custom and special designs.

Loading...

Overview

Angle Beam Transducers & Wedges

Angle beam transducers are commonly used in weld inspection. They are single element transducers and are used with a wedge to introduce a refracted shear wave or longitudinal wave into a test piece and for time-of-flight diffraction. We offer different wedge styles depending on your needs, including Accupath wedges for a better signal-to-noise ratio, contoured wedges, and wedges made for high-temperature applications.

Atlas European Standard Transducers

Designed to meet inspection criteria referenced in Europe and other parts of the world, Atlas® transducers feature LEMO® connectors, metric unit element diameters, and common frequencies such as 1, 2, and 4 MHz. They are available in dual element, angle beam, contact, and protected face styles.

AWS Transducers & Wedges

AWS transducers and wedges meet or exceed the specifications outlined in the American Welding Society’s structural welding code, section D1.1 for angle beam assemblies used in weld inspection. Snail and Accupath wedges are available based on the inspection requirements.

CDS Wedges

CDS wedges are used with a single element transducer to generate both a 30-degree shear wave and a 70-degree longitudinal wave in steel to detect and size ID-connected cracking using the 30-70-70 technique. Different size CDS wedges are available, and they are compatible with our replaceable miniature screw-in angle beam transducer, making them an economical choice.

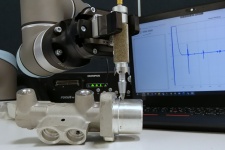

Contact Transducers

Contact transducers are single element, longitudinal wave transducers that are designed to be used in direct contact with the part or component being inspected. They are available in multiple styles, including standard, fingertip for difficult-to-access areas, and magnetic hold down for stationary positioning on ferrous materials. All are durable for use in industrial environments and have an acoustic impedance that matches most metals. They are used in many applications such as straight beam

flaw detection and thickness gaging, detecting and sizing delaminations, and inspecting plates, billets, bars, and other metallic and nonmetallic components.

Replaceable Delay Line Transducers

A replaceable delay line transducer has a single element and is heavily damped so that, when used with a replaceable delay line, it provides excellent near-surface resolution. Their higher frequency is also ideal for measuring very thin materials or locating small flaws using the direct contact method. Many styles are available, and they are commonly used for precision thickness gaging, straight beam flaw detection, and inspecting parts with limited contact areas.

Dual Element Transducers

A dual element transducer has two crystal elements housed in the same case, separated by an acoustic barrier. One element transmits longitudinal waves while the other acts as a receiver. The elements are angled, creating a V-shaped sound path in the test material. This pseudo-focus enhances the resolution in the focal zone. These transducers offer many advantages, including improved near-surface resolution, good coupling to rough surfaces, and reduced back-scattering noise in coarse-grained or

scattering materials. They are used in many applications such as measuring remaining wall thickness, corrosion/erosion monitoring, weld overlay inspection, and cladding bond/disbond inspection.

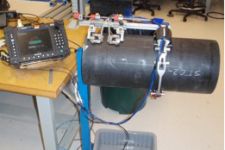

EMAT Transducers

EMATs (electromagnetic acoustic transducers) are single element transducers that use a magnetostrictive effect to transmit and receive ultrasonic waves. EMATs offer unique advantages—they can be used without couplant, there’s no need to remove external scale prior to an inspection, they can be used in contact or at a small distance from the surface, they can be used on hot parts, and they work well on small-diameter pipes.

High-Frequency Transducers

These single element contact or immersion transducers produce frequencies of 20 MHz up to 225 MHz. Their heavily damped, broadband design provides excellent time resolution while their short wavelengths provide superior flaw resolution capabilities. Focusing enables you to achieve very small beam diameters.

Immersion Transducers

An immersion transducer is a single element, longitudinal wave transducer with a quarter wavelength layer acoustically matched to water. They transmit ultrasound in applications where the test parts are partially or wholly immersed in water, enabling uniform, fast coupling to quickly scan parts. Add a focusing lens to increase the transducer’s sensitivity and performance in a particular area of a part. The transducers are available in standard, large diameter, slim line, and pencil case

styles. All are made with a corrosion-resistant 303 stainless steel case with chrome-plated brass connectors and RF shielding that improves the signal-to-noise ratio. They are used for automated scanning, in-line thickness gaging, and high-speed pipe, bar, tube, and plate inspection.

Immersion Special

Our special immersion transducers are made for specific applications such as measuring wall thickness, inspecting aluminum plating, and multi-element array flaw detection. They are available in a variety of styles, including side looking, paintbrush, extra-miniature, and i-R.

Immersion Accessories

These accessories, such as bubblers, tanks, reflective mirrors, and search tubes, aid in immersion applications and techniques.

Integral Angle Beam Transducers

These transducers provide superior signal-to-noise characteristics and contain a durable plastic wear surface that extends its life and reduces the chance of scratching critical components. Their short approach distance and height make them well-suited for limited access applications. Both right Microdot™ and straight Microdot connectors are available on some styles.

Normal Incidence Shear Wave Transducers

These single element contact transducers introduce shear waves directly into the test piece without the use of refraction. The shear waves propagate perpendicular to the test surface. The transducers are used for shear wave velocity measurements, calculating Young’s modulus of elasticity and shear modulus, and to characterize a metal’s grain structure. They are available in direct contact and delay line styles.

Protected Face Transducers

These versatile single element, longitudinal wave, contact transducers can be used with a delay line, protective membrane, or protective wear cap. When the transducer is used alone, the epoxy wear face provides good acoustic impedance matching to plastics, many composites, and other low-impedance materials. These transducers are used for straight beam flaw detection, thickness gaging, high-temperature inspections, and inspecting plates, billets, bars, and forgings.

RTD Transducers

RTD transducers are commonly used in the nuclear industry to inspect coarse-grained austenitic steel, to locate cracks under cladding, to detect and size IG stress corrosion cracking, automated scanning of pipes and pressure vessels, and in continuous high-temperature applications.

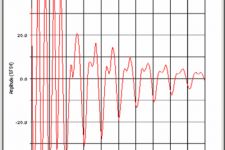

Spot Weld Transducers

These transducers provide optimal performance for testing spot-welds, including those used in automotive and industrial applications. Their broadband design gives our spot-weld transducers excellent signal-to-noise ratios, which is critical for distinguishing poor welds from good welds. They are available in many sizes in 0.5 mm increments so that you can find the proper transducer based on the weld nugget size. They can be used with a soft membrane captive water column or a hard tip delay

line.

Standard Angle Beam Transducers

Standard angle beam transducers have a large element size, enabling the inspection of thick components and providing a large scanning index. They are used with a wedge to introduce a refracted shear weave or longitudinal wave into a test piece. They come in a variety of styles, including high-temperature varieties, and are available with frequencies as low as 0.5 MHz. Standard, shear wave, and contoured wedges are also available.

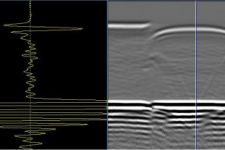

TOFD Transducers & Wedges

Time-of-flight diffraction (TOFD) transducers and wedges generate refracted longitudinal waves in steel and are commonly used to size cracks. The transducers are highly damped, offering excellent resolution in challenging applications. They have a sensitive composite element and are available in frequencies from 2.25 MHz to 15 MHz and in sizes from 3 mm (0.25 in.) to 12 mm (0.5 in.).

Test Blocks

Calibration and/or reference blocks should be used in every ultrasonic testing application. Standard blocks are available for angle beam calibrations and thickness calibrations of common materials. Blocks made from 1018 steel, 304 stainless steel, and 7075-T6 aluminum are commonly in stock, and custom blocks made from other materials are available on request. All blocks are measured using equipment traceable to the National Institute of Standards and Technology (NIST).

Transducer Cables

Transducer cables are available in a variety of connector styles, including BNC, LEMO®, UHG, and Microdot™ and a variety of types, such as heavy duty, waterproof, cables with handles, dual, armored stainless steel, and double shielded. Our standard cable lengths are 1 m (3.3 ft), 1.2 m (4 ft), and 1.8 m (6 ft), but custom lengths are available. All cables are 50 ohms impedance unless otherwise specified.

Couplant & Adaptors

Couplant is almost always necessary to provide acoustic coupling between the transducer and the test piece. We offer various types of couplant to suit virtually all applications. We also offer adaptors that enable you to connect different types of cables and probes to your flaw detector.

Resources

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.