X-STREAM

X-STREAM: Glass

|  |

Glass Cullet: Removal of Leaded and Heat Resistant Glass from Glass Cullet Streams

For some time, glass ceramics have been causing problems throughout the glass recycling industry. The melting behavior of glass ceramics is different from that of 'normal' glass; therefore, they will not dissolve in the melting tank at the glassworks, or dissolve only with great difficulty. This poses an array of problems; from serious damage and fire-hazard during the production process to defects or inclusions in the final product. The expanded use of glass ceramics and its tendency to turn up in recycling glass is on the rise; and it is problematic for glass collectors and processors to recognize glass ceramics visually when conducting inspection for incoming materials. In conjunction with the rising glass ceramics problem, glass recyclers are also facing the challenge of keeping the lead content of their glass cullet below a certain level, due to the increased stringency of legeslated regulations.

For some time, glass ceramics have been causing problems throughout the glass recycling industry. The melting behavior of glass ceramics is different from that of 'normal' glass; therefore, they will not dissolve in the melting tank at the glassworks, or dissolve only with great difficulty. This poses an array of problems; from serious damage and fire-hazard during the production process to defects or inclusions in the final product. The expanded use of glass ceramics and its tendency to turn up in recycling glass is on the rise; and it is problematic for glass collectors and processors to recognize glass ceramics visually when conducting inspection for incoming materials. In conjunction with the rising glass ceramics problem, glass recyclers are also facing the challenge of keeping the lead content of their glass cullet below a certain level, due to the increased stringency of legeslated regulations.

BT-Wolfgang Binder utilizes X-STREAM sensor technology in their REDWAVE XRF G glass sorting systems which offers glass cullet processors the ability to sort glass by elemental composition. The XRF sensor searches for certain elements such as Titanium, Zinc, Zirconium (which are typical markers for glass ceramics) and Lead. The system then efficiently extracts the contaminations by using air jet diversion. The REDWAVE XRF G systems by BT-Wolfgang Binder are capable of processing up to 28 tons/hour of glass cullet, extracting glass ceramics and leaded glass simultaneously.

BT-Wolfgang Binder utilizes X-STREAM sensor technology in their REDWAVE XRF G glass sorting systems which offers glass cullet processors the ability to sort glass by elemental composition. The XRF sensor searches for certain elements such as Titanium, Zinc, Zirconium (which are typical markers for glass ceramics) and Lead. The system then efficiently extracts the contaminations by using air jet diversion. The REDWAVE XRF G systems by BT-Wolfgang Binder are capable of processing up to 28 tons/hour of glass cullet, extracting glass ceramics and leaded glass simultaneously.

X-STREAM: Metal

|  |

Benefits:

- A high level of detection is guaranteed even in the presence of material which is dirty or otherwise contaminated

- Elemental analysis of the feed material

- Color independent recognition is possible (for example, for the sorting of aluminium, zinc, stainless steel)

- Sorting of alloys

Possible applications:

- Sorting of slag: separation of various metals from a mixture of slag and metals

- Sorting of aluminum

- Separation of various impurities of metallic origin (Cu, Zn, VA, brass, Pb, etc.)

- Separation of various impurities of different origin (e.g. wood, plastics) by means of camera technology

- Separation of aluminum alloys with a higher Zn or Cu content

- Sorting of stainless steels

- Separation of impurities such as Cu, Zn, brass, Pb, Sn in pure form and in the form of alloys. A pure fraction of steel / stainless steel is produced

- Separation of stainless steels from a mixture of steel and stainless steel

- Separation of stainless steels with Mo contents according to adjustable Mo concentration

- Separation of stainless steels with Ni contents according to adjustable Ni concentrations

- Sorting of non-ferrous metals and other metals

- Separation of Cu, Zn, brass, etc. in pure fractions

- Production of a pure Cu fraction

- Production of a pure brass fraction

- Separation of Cu, Zn, brass, etc. in pure fractions

- Sorting of precious metals

- Separation of materials containing Au

- Separation of materials containing Ag

- Special applications

- Sorting of Cu tubes

- Separation of Ag soldering joints

- In general: Sorting of various alloys on the basis of differences in the composition of the elements, e.g. presence of an element in alloy A, which is not existent in B and C, etc.

- Sorting of Cu tubes

Features

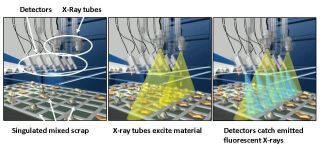

Rapid & Accurate Sorting TechnologyThe X-STREAM is a fully automated in-line system based on proven X-ray Fluorescence (XRF) that identifies scrap material by its chemical composition. |

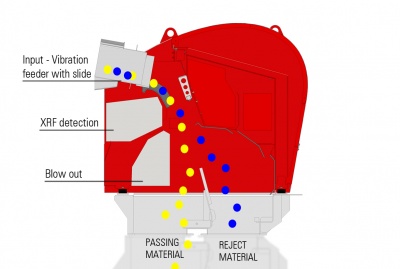

A typical automated XRF sorting system is being composed of a conveyor-mounted spectrometer module, typically containing multiple tubes and detectors to provide the ability to detect and analyze every single piece of scrap material. In only a few milliseconds, the chemical composition of each piece is being calculated, after which customer-defined sorting parameters will determine whether or not to divert that piece out of the main stream.

Key specifications include:

- Identification of elements chlorine (Cl) through uranium (U)

- High flux X-ray source

- Rugged, solid state, high resolution detector

- IR camera switching

- Millisecond signal processing

- Secure, yet flexible software platform

The X-STREAM's software configuration offers flexibility allowing quick, on-site software modifications to meet changing criteria and new market demands.

- Batch or continuous in-line mode

- Provided with individual components or complete turnkey systems

- Easily customized to meet a variety of process configurations

- Works with a wide variety of conveyors, feeders and diverters to meet performance needs

- Handles multiple applications in one facility

- Integrates multiple applications in one facility

The X-STREAM incorporates automated, high volume technology that sorts scrap and recyclable material based on highly specific material chemistry, not physical property. With XRF, sorting by elemental composition provides the recycling industry with new sorting opportunities and unique solutions for current challenges; increasing the level of scrap sorting and moving closer to the ideal goal of 100% recycling. This unique system works in tandem with eddy current, induction sorters, and media separation equipment to improve recoveries and increase asset value for metal and glass recyclers. It helps provide maximum value for processed material. It's easy, fast and cost-effective.

Advantages Include:

- Highly accurate sorting - typically >95%

- Highly efficient separation - typically >90%

- Capacities of many tons per hour available

- Flexibility to change sort criteria to meet market demands

- Highest value product - in one pass

- Industrially hardened and reliable for low CoO

Automated XRF sensor technology can be applied to many different types of scrap material, and can therefore serve various recycling industries. Extracting copper meatballs from ferrous shred, sorting of non-ferrous metals by composition or alloy grade and sorting glass are a few of many examples where the X-STREAM technology can be beneficial for scrap processors. Olympus Innov-X is expert in XRF technology and aims to focus on developing and manufacturing the X-Stream sensors only. They are currently being used by sorting system manufacturer BT-Wolfgang Binder who implements the X-Stream sensors into their proven sorting systems.

For more information on X-STREAM sorting systems, please visit BT-Wolfgang Binder GmnbH.