![]()

Nozzle

Background

A vehicle’s overall quality is equal to the sum of its parts, and it is imperative for manufacturers to maintain rigid standards of excellence for every component. Manufacturers must also take into account requirements such as emission reduction, fuel efficiency, long-term durability, and regulatory standards. The increasing complexity of auto parts and components also requires manufacturers to place a strong emphasis on material characteristics, fitting tolerances, and technical cleanliness, which all play a strong role in the long-term durability, durability, and life-expectancy of the final product.

Application

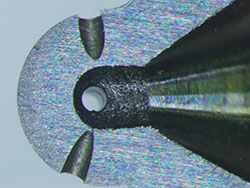

During operation, a needle blocks the fuel injection aperture at the tip of the nozzle. The needle is electromagnetically lifted to provide pressurized injection of the fuel. Burrs and other contaminants left over from the manufacturing process can obstruct the uniform injection of fuel and result in poor performance or unstable combustion, making it essential for manufacturers to thoroughly inspect their components before installation.

The Olympus solution

Olympus SZ and SZX stereoscopic microscopes provide low-magnification, distortion-free results for clear, fast optical inspection of fuel injection apertures and nozzle tips. The SZX16 stereomicroscope has a wide, 16.4X zooming ratio for seamless observation of the entire sample down to detailed features, while an apochromatic optical system provides clear image acquisition regardless of the magnification rate. Additionally, the SZ61 microscope’s improved optical system reduces eye fatigue during extended observations, while the ocular lens stays locked onto the image when changing postures during observation for enhanced efficiency

Nozzle: Cross-section |

Nozzle tip: Stereoscopic microscope imagery | ||

Nozzle: External | |||