To avoid unscheduled downtime leading to production delays and financial loss, oil and gas processing facilities must conduct thorough, uncompromising maintenance of their extensive assets as efficiently as possible. |

|

Precise Articulation, Regardless of LengthThe scope articulation system driven by air pressure gives powerful scope tip angulation regardless of unrolled scope length. You can manipulate the insertion tube by just pulling out any length up to 30 m (98 ft), depending on inspected objects. The compact design with an integrated air compressor can be easily carried anywhere in a plant. |

Track Your Location as You GoThe gravity sensor automatically rotates the live image, synchronizing it to the actual direction of gravity regardless of the scope’s orientation, and the insertion length indicator enables you to track the insertion tube’s position. These features give you the ability to identify the exact location of a defect in a long pipe, increasing the efficiency of your follow-up scrutiny with other nondestructive testing (NDT) methods, such as a thickness gauge and ultrasonic phased array inspection. |

Navigate Tight Spaces EasilyThe tough Tapered Flex insertion tube is designed with optimized stiffness for greater control and flexibility. Combining the guide head and the optional pushing rod enables you to easily and quickly insert the scope into deep areas of a pipeline, passing through an elbow even from 15 meters (50 ft) away. |

See Clearly in Oily EnvironmentsDuring remote visual inspection (RVI) of pipelines, residual oil and water can obstruct your view and blur your images. Grooves on the IPLEX videoscope’s oil clearing tip adaptor use capillary action to draw oil away from the lens, keeping your images clear and objects visible. This saves time since it prevents needing to stop your inspection and withdraw the tube to wipe oil off the scope tip. In addition, the guide head assists your scope insertion, helping you to navigate past standing oil and water in the pipe. |

Live Streaming for Remote DiagnosisThe USB wireless LAN adaptor enables you to share live images with colleagues at a distance. Using the videoscope’s wireless connectivity, you can exploit common video-conferencing applications to communicate with inspection experts and collaborate on flaw diagnosis. |

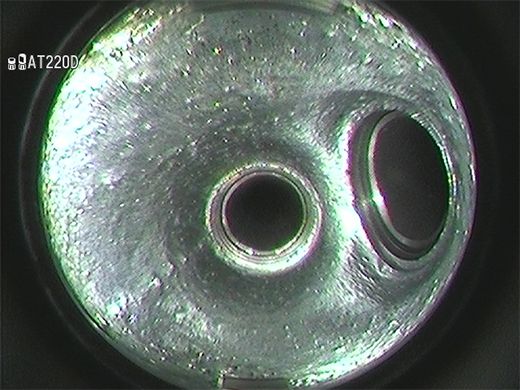

Get the Whole Picture Inside the Pipe

To gain a comprehensive view inside a pipe, use the 220-degree fisheye optical tip adaptor. Using real-time image distortion correction, the adaptor’s lens enables you to switch between 120°, 180°, and 220° views to clearly see the entire inner wall of a wide pipe.

220-degree fish-eye |

120-degree field of |

|

Main Visual Inspection Areas in Oil and Gas Processing Facilities

- Pipelines with elbows and tees

- Valves and seals

- Heat exchanger and boiler tubes

Recommended Product

IPLEX GAir Videoscope |