Glass is an easily recyclable material if processors can accurately and cost effectively separate clean, furnace-ready glass cullet from other commingled and/ or contaminated waste, such as ceramics and metals.

The X-STREAM-G high volume glass sorting and separating system uses proven X-ray Fluorescence (XRF) technology to sort glass by highly specific material chemistry, providing the most economically viable solution to identify and extract specific cullet contaminants including:

- Leaded Crystal

- Glass Ceramic, PyroCeram, High Temp Glass

- Cu, W, Al and other metals

- Pb, Br, Sn, Sb and other toxic elements

X-STREAM-G Advantages:

- Rapidly determine by chemistry - not density

- Capacities of many tons per hour available

- Flexibility to handle new applications to meet market demands

- "See" a wider range of materials

- Industrially hardened and reliable for low CoO

X-STREAM-G Typical PerformanceThe X-STREAM-G is robustly engineered to process high volumes of materials, with minimal loss of recyclable cullet. Processing volumes are scalable to meet client requirements. Typical analysis time is on the order of a few milliseconds, with high levels of accuracy.

X-STREAM-G Operation ModeThe X-STREAM-G can be placed before or after crushing equipment and detects glass contaminants as the materials move onto slide-ways or conveyors and then diverts them from the processing line.

|

X-STREAM-G Performance Data

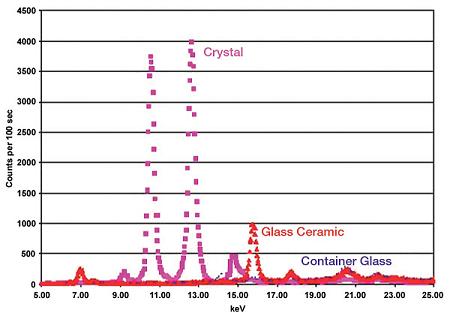

Glass recyclers/processors need to detect small pieces of glass ceramic and leaded crystal in cullet. Specific elemental markers have been used to successfully identify and remove these materials from the clean cullet.

Spectral comparison of leaded crystal, glass ceramic, and container glass. Taken under typical dwell times of <100 ms.