Bar Inspection Solutions

Our NDT bar inspection solutions employ ultrasonic phased array, eddy current array, and X-ray fluorescence spectroscopy technologies to test materials for flaws and to determine their composition.

| Bar Inspection System: System Overview RTIS - Rotating Tube Inspection System IN-LINE ERW Tube & Pipe Inspection System |

Bar Inspection Systems

Vanta™ iX In-Line XRF Analyzer

The Vanta iX in-line X-ray fluorescence (XRF) analyzer gives you confidence in your products by automating material analysis and alloy identification on the manufacturing line. Built to operate 24/7 in industrial environments, the system delivers instant results for 100% inspection and continuous quality control.

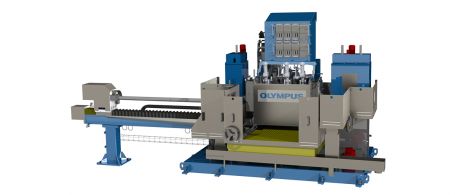

BIS PA: Bar Inspection System—Phased Array

RBIS: Rotating Bar Inspection System

BIS ECA: Bar Inspection System—Eddy Current Array

Bar Inspection Resources

9 Reasons to Automate Material Analysis with the Vanta™ iX In-Line XRF AnalyzerThe Vanta iX in-line X-ray fluorescence (XRF) analyzer is ideal for automating material analysis and alloy identification (ID) on the manufacturing line. Learn more here. |

|

Automated Surface Inspection Using Eddy Current Array TechnologyInspecting the surface of long bars and tubes has been a requirement in the metal manufacturing industry for many years. Learn more here. | |

How to Automate Sampling and Analysis of Ores and Mined MaterialsAccurate chemical analysis can provide vital data to enhance mining operations, such as improved extraction at mine sites and the optimized blending of mined material. Learn more here. |

Bar Inspection Video Resources

Vanta™ iX In-Line XRF Analyzer for Automated Material Analysis and Alloy ID | |

Integrated Material Verification Using In-Line XRF Analysis | |

Bar Inspection System: System Overview | Bar Inspection System: System Overview RTIS - Rotating Tube Inspection System IN-LINE ERW Tube & Pipe Inspection System |