As any new parent will tell you, feeding a newborn is not easy. With a hungry baby crying to be fed, the last thing a parent needs is a bottle or breast pump that doesn’t work or, worse yet, contains a defect or foreign particle that could harm their child.

Manufacturers of baby products, such as bottles and breast pumps, take quality control especially seriously. They use industrial microscopes to help validate that there are no flaws or safety issues with the product and to check that it meets the design specifications so that it will function correctly.

Baby Product Quality Control Concerns

Industrial microscope quality control (QC) inspections of baby products may include:

- Checking for foreign particles and verifying the composition of any particles to trace the source of contamination

- Measuring a bottle’s wall thickness and nipple diameter to validate they meet the specs

- Inspecting the quality of printed text and numbers to verify durability and readability

QC Challenges Faced by Baby Bottle Manufacturers

When imaging baby products with an industrial microscope, QC inspectors face certain challenges:

- Samples that are highly reflective

- High-quality macro imaging is difficult to achieve

- Lack of different observation methods

- Long analysis times that cause a backlog

DSX1000 Digital Microscope Solution

Our advanced DSX1000 digital microscope is used in baby product manufacturing for quality control (QC) as well as in R&D to make design improvements. Compared with conventional industrial microscopes, the DSX1000 microscope’s capabilities resolve many issues for baby product inspection:

- Acquires high-quality 2D and 3D images of samples

- Provides good macro view of samples thanks to its stitching function

- Offers multiple observation methods to achieve proper visualization of the sample

- Easy to use and is equipped with helpful tools to improve inspection, measurement, and analysis productivity

Baby Products Under the Microscope

The following are some sample images acquired with the DSX1000 microscope to illustrate specific use cases:

|  |

|---|

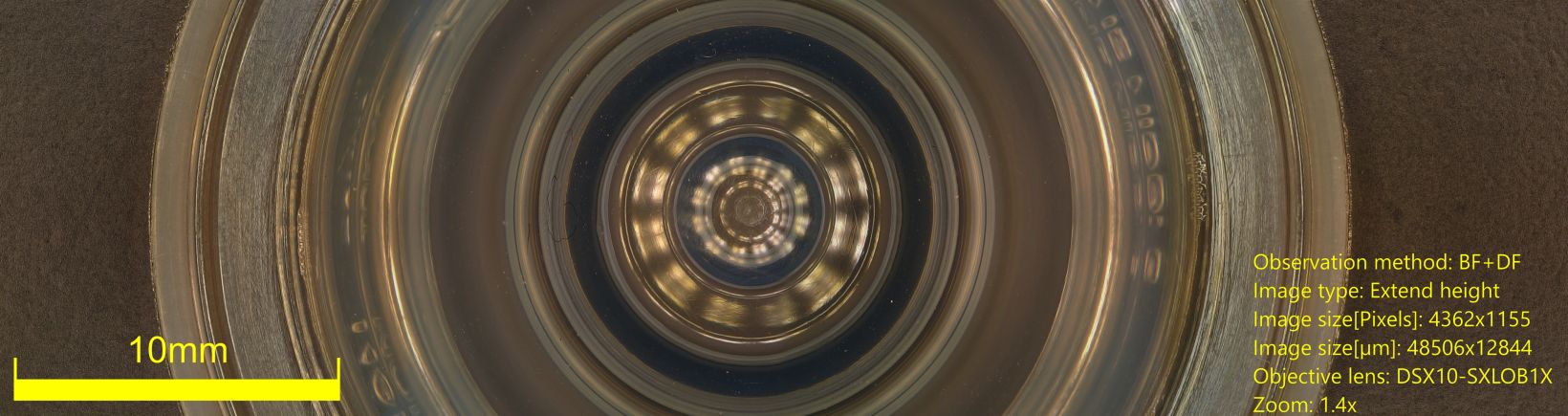

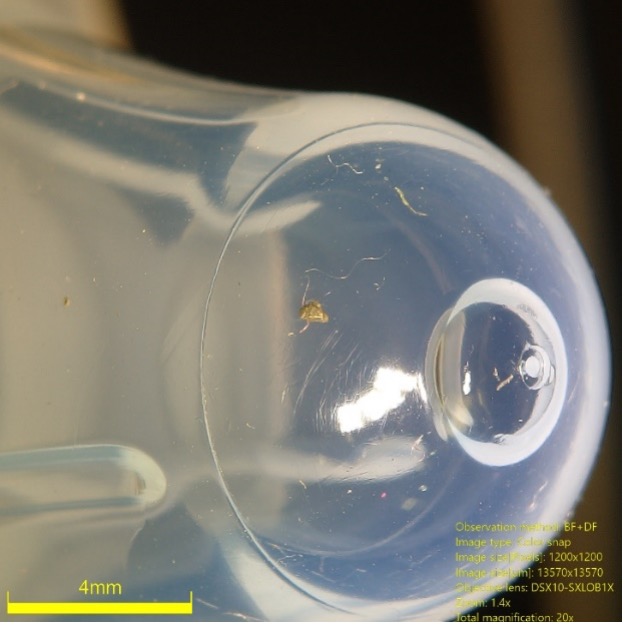

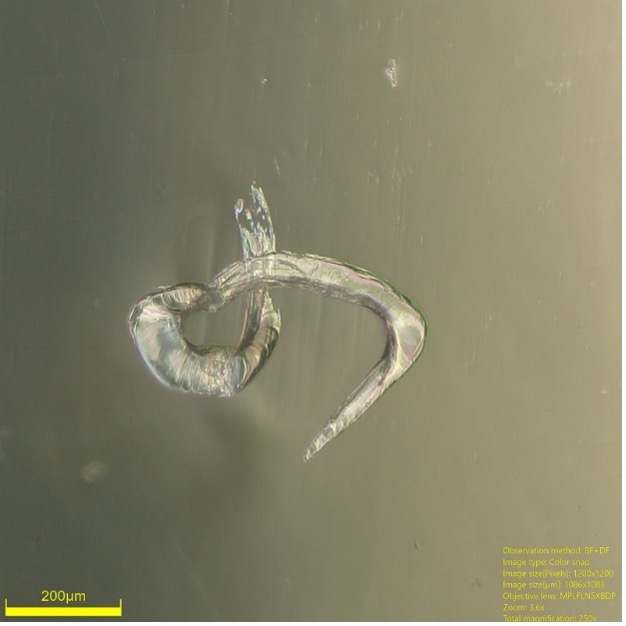

Foreign particle observation on parts with reflective surfaces:

To acquire these images, the user chose MIX illumination (BF + DF), which combines the visibility of brightfield and detection capabilities of darkfield. On the left, a particle in a baby bottle nipple was magnified 20 times and, on the right, another foreign particle was observed at 250x.

In the image above, 40x magnification and polarization observation was used to validate whether the foreign particle (the red dot) was metallic.

Inspectors using the DSX1000 microscope can quickly switch between up to 6 observation modes, including oblique, brightfield, darkfield, polarization, differential interference contrast (DIC), and MIX, to find the optimal lighting condition and easily capture high-quality images. The tilting observation head is also practical to view the sample from different angles.

|  |

|---|

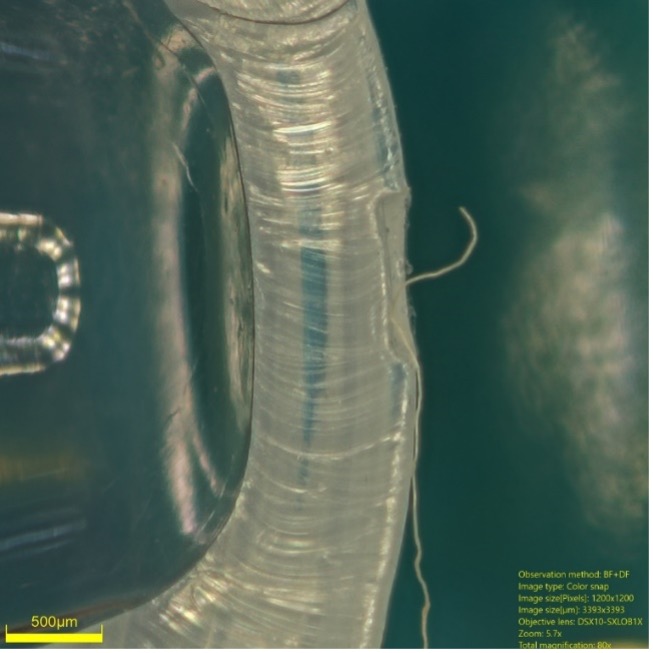

Measuring to validate specification compliance:

On the left, the diameter of the nipple was observed at 40x (using MIX illumination) and, on the right, another component was observed and measured at 80x.

The intuitive software interface enables users to easily familiarize themselves with its analysis tools with minimal training—from acquiring and measuring 3D images to generating reports.

This ease-of-use, in turn, improves the productivity of QC and R&D departments at accomplishing their microscopy-based tasks.

Here 3D images of the bottle nipple, including its profile, were generated to measure and validate its shape.

The DSX 1000 microscope’s profile measurement functionalities enable you to easily set and measure the steps between any two points. Unlike contact-based measuring tools, the measurement assist tools enable you to accurately specify points you want to measure and, once defined, the measurement data is automatically acquired.

Inspecting printing quality:

Capable of acquiring high-resolution images with a magnification range of 23x to 8220x, the DSX 1000 microscope enables low-magnification macro-level observations as well as high-magnification observations at the micron level, such as the image above of the print on a bottle.

Easy Macro-to-Micro Imaging

The DSX 1000 software also offers an automatic image stitching function to capture high-resolution panoramic images with a high field of view when required. To facilitate the image stitching, a macro map helps you easily locate points on the sample at lower magnification.

The low-resolution macro map on the right shows the location of the high-magnification image on the left.

The tools offered by the DSX 1000 microscope to assist quality control and assurance can facilitate the tasks involved with baby product inspections for manufacturers. That, and the high-quality and powerful imaging performance, gives them an advantage compared with conventional microscopes.

To learn more about the DSX 1000 digital microscope and the different models available, go to olympus-ims.com/microscope/dsx, or get in touch via the button below.

Related Content

5 Advantages of the DSX1000 Digital Microscope

From Macro to Micro: How Digital Microscopes are Changing Industrial Inspections

Modern Digital Microscopes: Jack of All Trades, Master of All

Get In Touch