- Home

- Microscope Solutions for Materialography

- Layer/Coating Thickness Measurement Solutions

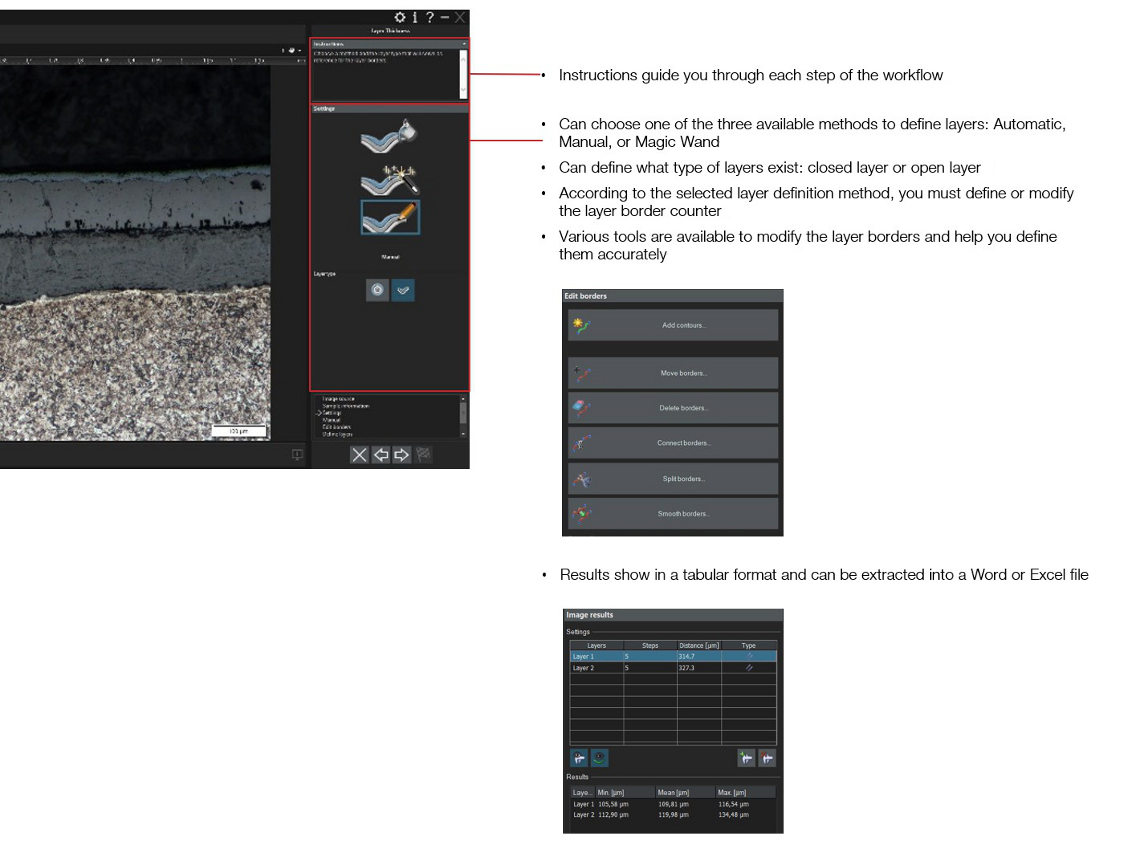

Layer Thickness Measurement Solutions

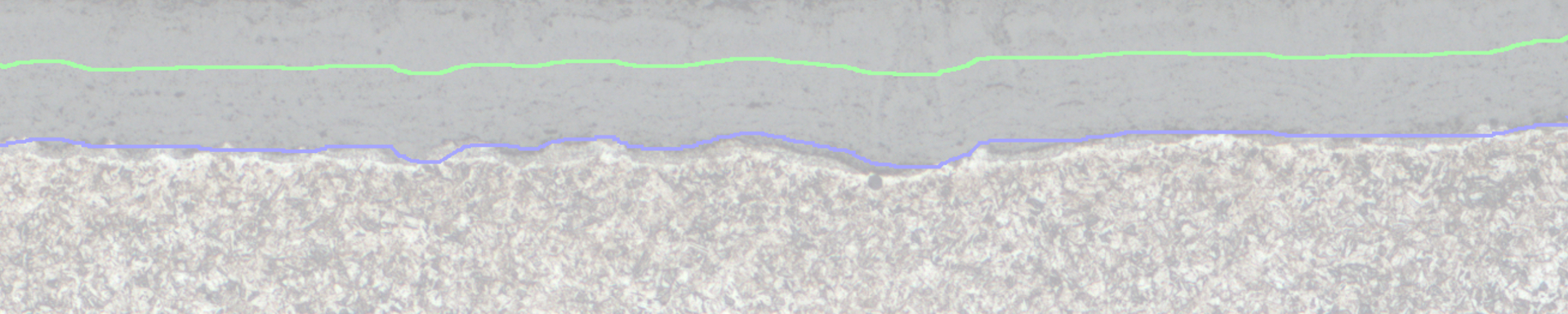

Many industries, such as automotive, aerospace, and oil and gas, use a multi- or monolayer coating as a protective layer against corrosion, fire, heat, stress, and ultraviolet (UV) light. Coatings can also be applied to add functional surface properties, such as waterproofing, and to fulfill decorative purposes, such as adding color and special texture to the surface. Producing a homogenous coating of a certain thickness is critical for product quality.

Our image analysis software offers a special workflow to measure coating layer thickness and generate reliable, reproducible results.

Measurement requirements:

- Sample should be prepared and mounted properly

- Different layers can be revealed using an etching process (method described in ASTM B487)

- Each layer is defined by two borders and a neutral fiber

- The neutral fiber is a reference line, which specifies the layer's course. The software automatically defines the neutral fiber.

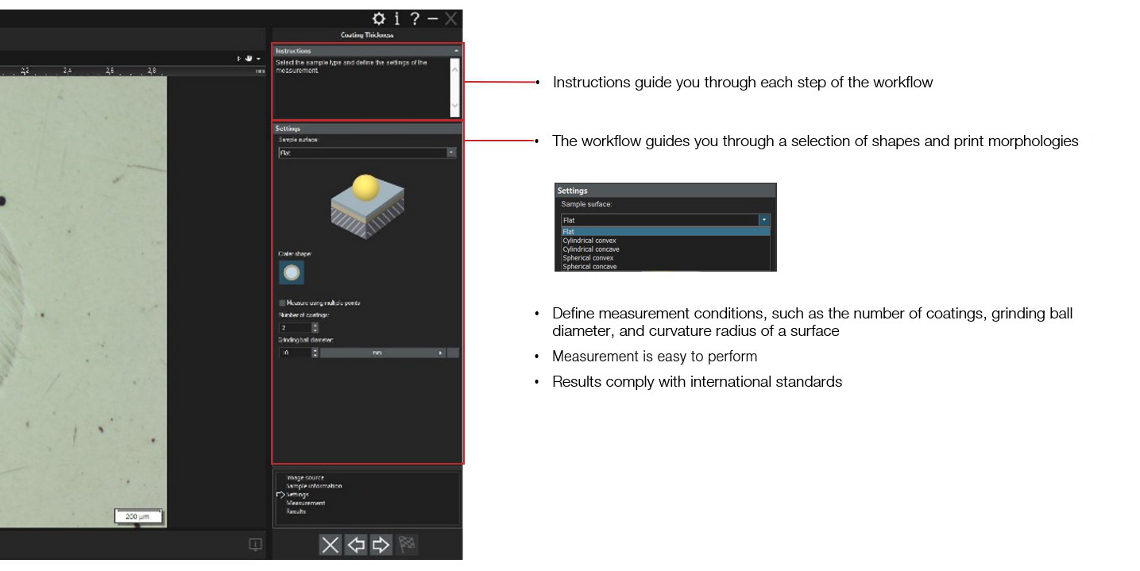

Coating Thickness Measurement Solutions

In the automotive, painting, and appliance industries, coating thickness measurement is an important analysis to check the quality of the manufactured part. A high-quality homogenous coating can achieve certain mechanical functions, appealing finishes, or corrosion protection in different applications. As a result, it is critical to have a reliable solution to measure coating thickness.

Our image analysis software offers a guided workflow using the grinding ball method (i.e., calottes) to measure coating thickness in the range of 0.5 μm to 50 μm.