Functionality

Observation and Analysis Tools

Leading-Edge Analysis Tools

The MX63 series’ versatile observation capabilities provide clear, sharp images so users can reliably detect defects in their samples. New illumination techniques and image acquisition options within PRECiV image analysis software give users more choices for evaluating their samples and documenting their findings.

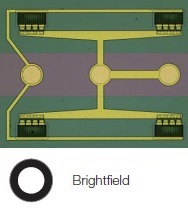

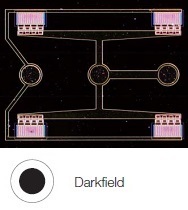

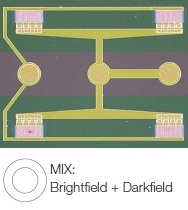

The Invisible Becomes Visible: MIX Observation and acquisition

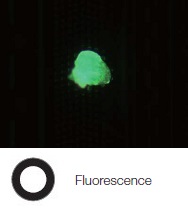

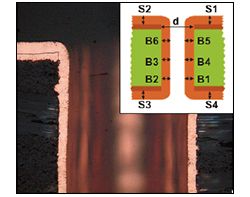

MIX observation technology produces unique observation images by combining darkfield with another observation method, such as brightfield, fluorescence, or polarization. MIX observation enables users to view defects that are difficult to see with conventional microscopes. The circular LED illuminator used for darkfield observation has a directional darkfield function where only one quadrant is illuminated at a given time. This reduces a sample’s halation and is useful for visualizing a sample’s surface texture.

Structure on semiconductor wafer

|

|

|

|

| ||

The IC pattern is unclear. | The wafer color is invisible. | Both the wafer color and IC pattern are clearly represented. |

Photoresist residue on a semiconductor wafer

|

|

|

|

| ||

The sample itself is invisible. | The residue is unclear. | Both the IC pattern and residue are clearly represented. |

Condenser

|

|

|

|

| ||

The surface is reflected. | Several images with directional darkfield from different angles. | By stitching together clear images with no halation, a single crisp image of the sample is created. |

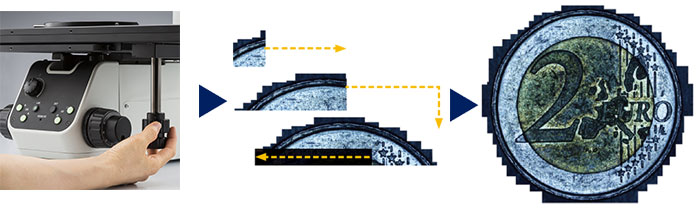

Easily Create Panoramic Images: Instant MIA

With multiple image alignment (MIA), users can stitch images together quickly and easily simply by moving the KY knobs on the manual stage—a motorized stage is not necessary. PRECiV software uses pattern recognition to generate a panoramic image, giving users a wider field of view.

Instant MIA image of a coin

Create all-in-focus images: EFI

The Extended Focus Imaging (EFI) function within PRECiV captures images of samples whose height extends beyond the depth of focus of the objective and stacks them together to create one image that is all in focus. EFI can be executed with either a manual or motorized Z-axis and creates a height map for easy structure visualization. It is also possible to construct an EFI image while offline within Stream Desktop.

Stud bump on an IC chip

Capture Both Bright and Dark Areas Using HDR

Using advanced image processing, high dynamic range (HDR) adjusts for differences in brightness within an image to reduce glare. HDR improves the visual quality of digital images thereby helping to generate professional-looking reports.

|

|

|

|

|

| |||

Some areas are glaring. | Both dark and bright areas are clearly exposed by HDR. | The TFT array is blacked out due to the brightness of the color filter. | The TFT array is exposed by HDR. |

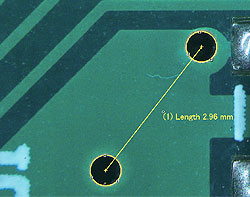

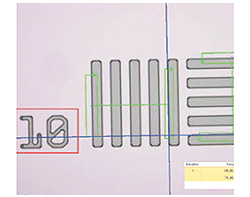

From Basic Measurement to Advanced Analysis

Measurement is essential to quality and process control and inspection. With this in mind, even the entry-level PRECiV software package includes a full menu of interactive measurement functions, with all measurement results saved with image files for further documentation. In addition, the PRECiV Materials Solution offers an intuitive, workflow-oriented interface for complex image analysis. At the click of a button, image analysis tasks can be executed quickly and precisely. With a significant reduction in processing time for repeated tasks, operators can concentrate on the inspection at hand.

Basic measurement (pattern on a printed circuit board) | Throwing power solution (Cross section of a through hole of PCB) |

Automatic measurement solution (Wafer structure) |

> Learn more about PRECiV software

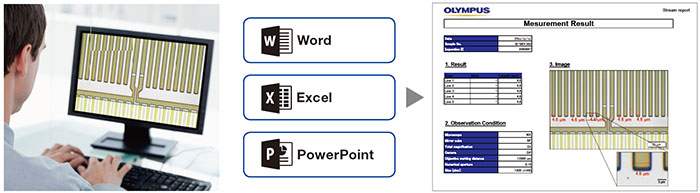

Efficient Report Creation

Creating a report can often take longer than capturing the image and taking the measurements. PRECiV software provides intuitive report creation to repeatedly produce smart and sophisticated reports based on pre-defined templates. Editing is simple and reports can be exported to Microsoft Word or PowerPoint software. In addition, PRECiV software’s reporting function enables digital zooming and magnification on acquired images. Report files are a reasonable size for easier data exchange by email.

> Learn more about PRECiV software

Advanced Designed to Support Cleanroom Conformity

The MX63 series is designed to work in a cleanroom and has features that help minimize the risk of contaminating or damaging samples. The system has an ergonomic design that helps keep users comfortable, even during prolonged use. The MX63 series complies with international specifications and standards, including SEMI S2/S8, CE, and UL.

Optional Wafer Loader Integration ― AL120 System*

An optional wafer loader can be attached to MX63 series to safely transfer both silicon and compound semiconductor wafers from a cassette to the microscope stage without using tweezers or wands. Renowned performance and reliability enable safe, efficient front and back macro inspections while the loader helps improve productivity in the laboratory.

MX63 combined with the AL120 wafer loader (200 mm version)

* AL120 is not available in EMEA.

Fast, Clean Inspections

The MX63 series delivers contamination-free wafer inspections. All motorized components are housed in a shielded structure, and antistatic processing is applied to the microscope frame, tubes, breath shield, and other parts. The rotation speed of the motorized nosepieces is faster and safer than manual nosepieces, decreasing the time between inspections while keeping the operator's hands below the wafer, reducing potential contamination.

Antistatic breath shield |

Motorized nosepiece |

System Design Achieving Efficient Observations

The XY stage is capable of both coarse and fine stage movements thanks to the combination of a built-in clutch and the XY knobs. The stage helps make observations efficient, even for large samples, such as 300 mm wafers.

The tilting observation tube’s extensive range enables operators to sit at the microscope in a comfortable posture.

Stage handle with built-in clutch |

The tilting observation tube providing comfortable posture |

Accepts All Wafer Sizes

Wafer holders and glass plates | The system works with various types of 150–200 mm and 200–300 mm wafer holders and glass plates. Should the size of the wafters change on the production line, the microscope’s frame can be modified at minimal cost. With the MX63 series, different stages can be used to accommodate 75 mm, 100 mm, 125 mm, and 150 mm wafers on the inspection line. |