本应用说明探讨了如何透过漆层或类似涂层准确测量金属管道、箱罐、梁柱、船体及其他结构的剩余壁厚。

透过漆层或涂层测量金属厚度的挑战

在许多工业和石化行业的维护过程中,需要透过一层或多层涂漆或类似的非金属涂层,对那些易受腐蚀金属的剩余壁厚进行测量。使用常规超声测厚仪对带有漆层或类似涂层的材料进行测量时,会产生测量错误:测量厚度值通常会比金属材料的实际厚度多两倍以上的涂层厚度,因为涂层材料的声速要比金属的声速慢得多。针对这个问题有两个解决方案:回波到回波测量和穿透涂层测量。 |

|

用于回波到回波和穿透涂层测量的设备

我们的两种腐蚀测厚仪:39DL PLUS和45MG, 均具有回波到回波和穿透涂层功能。回波到回波测量通常使用以下双晶探头之一进行:D790、D791、D797或D798。穿透涂层测量需要使用两种专用双晶探头(D7906-SM和D7908)中的一种进行。

由于双晶探头对粗糙表面和点蚀缺陷的检测效果超好,长期以来,这种探头已经成为腐蚀测量应用的行业标准。对于所有常见的腐蚀测厚应用,一般都建议用户使用这类探头。在某些应用中,如对带有光滑漆层的金属材料进行的检测,由于需要较高的测量精度,可能会建议用户使用单晶延迟块探头。

透过油漆测量金属厚度的工作原理

钢中的纵波声速一般约为5,900 m/s,而漆层和类似涂层的声速一般要低于2,500 m/s。常规超声测厚仪在测量带有漆层的金属材料的整个厚度时,会错误地使用钢中声速测量漆层,这就意味着测出的漆层厚度至少是其实际厚度的2.35倍(两个声速的比率)。在涂层很厚且误差要求严格的情况下,因涂层而产生的错误会对总体测量结果造成严重的影响。这个问题的解决方案是对漆层厚度进行测量,然后再从总体厚度测量值中减去漆层厚度。

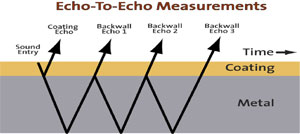

回波到回波厚度测量方式只涉及一项业已成熟的技术,即对两个连续底面回波之间的时间间隔进行及时,连续的底面回波代表声波在被测材料中传播的两次连续的往返声程。在测量带有漆层的金属材料时,这些多重底面回波只发生在金属内部,不会在漆层上产生,因此每对相邻回波之间的时间间隔(如:底面回波1到2,底面回波2到3等)只代表金属的厚度,而没有包含漆层的厚度。

穿透涂层测量要使用一种已获专利的软件方法,来确定声波在涂层中的一次往返声程所代表的时间间隔。这个时间间隔用于计算和显示涂层厚度。通过从总测量值中减去这个时间间隔的方法,仪器还可以计算并显示金属基材的厚度。

比较回波到回波和穿透涂层测量技术

这两种技术各有利弊。用户在为具体应用选择适当测量方法时,应该考虑到这些因素。

回波到回波技术的优点:

- 可以使用各种普通探头

- 通常可以透过粗糙表面的涂层对材料进行测量

- 使用适当的探头,可在高达约500 ℃的高温下工作

回波到回波技术的局限性:

- 需要多重底面回波,但是在严重腐蚀的金属中可能不会获得这些回波

- 与穿透涂层技术相比,可测厚度范围可能会更有限

穿透涂层技术的优点:

- 可以对各种厚度的金属进行测量,钢中可测厚度范围一般从1毫米到50毫米以上

- 只需要一个底面回波

- 测量带有点蚀缺陷的材料时,可以更准确地测量金属的最小剩余厚度

穿透涂层技术的局限性:

- 涂层必须为非金属材料,且厚度至少为0.125毫米

- 涂层表面必须相对光滑

- 要求使用两种特定探头的一种

- 最高表面温度大约为50 ℃

回波到回波和穿透涂层测量的程序

使用39DL PLUS和45MG测厚仪及适当的探头,启动和执行回波到回波和穿透涂层测量的操作程序,分别在两种测厚仪的操作手册中有详细说明。请参阅测厚仪的手册了解这些信息,并详细了解有关声速校准的推荐程序,以及在需要时优化增益和优化空白等方面的详细信息。

穿透涂层模式的测量范围

穿透涂层功能使用D7906-SM或D7908探头,只能对非金属涂层进行测量,如0.12毫米厚或更厚的漆料或环氧树脂材料。如果您测量的是一种带涂层的钢制样件,但是仪器屏幕上却没有显示涂层的厚度值,这就说明涂层的厚度低于穿透涂层功能所要求的最小厚度值,或者说涂层的厚度不能被穿透涂层功能测量到。不过在很多情况下,测厚仪还是可以测量到涂层的厚度,然后再将涂层的厚度从整个厚度值中减去,并将钢材料的厚度显示在屏幕上。您还可以尝试使用回波到回波功能进行测量,或者您可能需要先将涂层去掉,再进行测量。

穿透涂层模式可以测量的金属厚度范围一般从大约1毫米到50毫米以上,具体的可测厚度取决于金属的声学特性和样件内表面的条件。

回波到回波模式的测量范围

在回波到回波模式下,厚度范围取决于探头的选择、所用测厚仪类型,以及被测金属的声学特性和表面状况。根据定义,回波到回波测量要求至少出现两个底面回波,因此在某些极端情况下无法使用这个功能,如在严重腐蚀、非常粗糙、具有高度散射性或高度衰减性材料中,不能生成第二个多重底面回波。在这种情况下,如果可以,应该使用穿透涂层功能。

39DL PLUS和45MG测厚仪典型的回波到回波可测厚度范围如下:

| 探头类型 | 可测厚度范围* |

| D798 | 1.5 mm至7.50 mm |

| D790/D791 | 2 mm至50 mm |

| D797 | 12.5 mm至125 mm |

| M201 | 1.25 mm至12.5 mm |

*可测厚度范围取决于材料、表面状况和温度。