Doubler Edge Skin Crack Inspection Solution

Loading...

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.

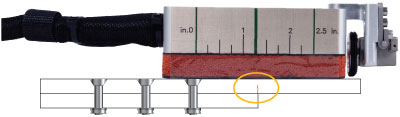

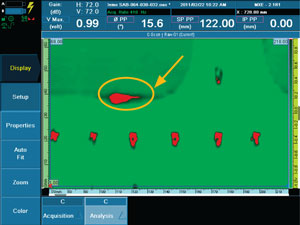

Olympus NDT is pleased to introduce the new Doubler Edge Skin Crack Inspection solution, which utilizes the latest ECA technologies for subsurface detection. Drastically reduced inspection times, C-scan imagery, large probe coverage, encoded scan, and data/setup recording capabilities are just a few of the many benefits of OmniScan technology. Intuitive imagery with the C-scan allows for higher probability of detection and better reproducibility, and also makes it easier to identify the rivet row and edge on-screen. Thanks to its wide coverage, probe positioning is not critical. This coverage also enables both edges of the doubler to be covered during the same scan.

In comparison with the conventional method of performing this type of inspection, this solution is a major step forward in terms of reduced inspection time.

Benefits of the eddy current array (ECA) Doubler Edge Skin Crack Inspection solution

The doubler and rivets appear on-screen for optimal probe positioning. The green/red color palette offers easy data interpretation.

Display showing C-scan, impedance plane, and strip chart views. Note that the doubler edge and rivets are clearly visible.

You are being redirected to our local site.