As the demand for electric vehicles accelerates globally, so does the need for high-performance lithium-ion (Li-ion) batteries. While Li-ion batteries play an important role in the move to more sustainable energy sources, they need to be responsibly managed at the end of their life.

Figure 1. Spent lithium-ion car battery

Properly recycling batteries promotes a circular economy where battery materials are kept in use to reduce waste and pollution. Extracted materials can be remanufactured into new batteries or used for other applications, reducing the need for raw materials in new production.

This application note examines the value of recycling Li-ion batteries, shares the battery recycling process, and highlights how portable X-ray fluorescence (XRF) technology aids the effective recovery of valuable metals from battery waste.

The Importance of Li-Ion Battery Recycling for a Greener Future

Lithium-ion battery recycling is an important process in the pursuit of a more sustainable future. From powering electric vehicles to storing renewable energy, Li-ion batteries play a pivotal role in modern society.

However, the improper disposal of batteries poses environmental and resource challenges. Li-ion battery recycling is crucial as it enables the recovery of valuable metals such as lithium (Li), cobalt* (Co), and nickel (Ni), reducing the need for resource extraction and promoting a circular economy. Battery recycling also mitigates environmental impact by preventing the hazardous materials in batteries from leaching into soil and water sources, as well as minimizing greenhouse gas emissions associated with the manufacturing of new batteries.

Through responsible recycling practices, the lifecycle of batteries is extended to maximize their economic and environmental value. Battery recycling is an essential practice to create a sustainable energy landscape, preserve natural resources, and minimize environmental harm.

The Li-Ion Battery Recycling Process

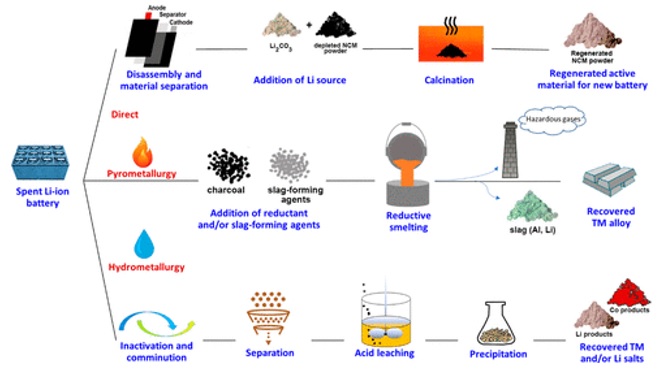

To achieve effective resource recovery and reduce environmental impact, the Li-ion battery recycling includes several stages:

- First, used batteries are gathered from a variety of places, including recycling agencies and facilities for electronic garbage. To avoid cross-contamination, these batteries are classified based on their chemistry, size, and type.

- Next, the batteries go through a pre-treatment stage where the electrolytes and external casings or packing are removed. Li-ion batteries are fully discharged prior to processing to remove the risk of spontaneous combustion. The batteries are prepared for further processing, then mechanically shredded or crushed into smaller pieces. By exposing the internal components of the battery, the valuable components can be extracted and separated more effectively.

- Multiple specialized processes are used to extract the batteries’ valuable metals, including lithium (Li), cobalt (Co), nickel (Ni), lead (Pb), and cadmium (Cd) (see Figure 1). There is less need to mine for resources because these metals can be recycled and used to make new batteries or other products.

- Recovering plastic components is another aim of recycling. Plastic elements can be recycled or used in fuel after being separated from the battery shards, opening another opportunity for resource preservation.

- The electrolyte from some batteries, such as Li-ion battery cathode (known as black mass or black powder), can be recovered using a number of proprietary processes and repurposed or processed for proper disposal. Potentially dangerous compounds are properly managed thanks to this process. Li-ion battery cathode (black mass), which requires rework during battery manufacturing, can be recovered, tested and reused.

- Environmental regulations are strictly followed throughout the entire battery recycling process. This includes minimizing any potential harm to the environment and human health through proper disposal of hazardous waste, wastewater treatment, and emission control.

- The last step is to properly dispose of any leftover waste that cannot be recycled or recovered while adhering to the established laws and regulations.

Figure 2. Recycling process for spent lithium-ion batteries (Zachary J. Baum, Robert E. Bird, Xiang Yu, and Jia Ma. ACS Energy Letters 2022 7 (2), 712–719)

Lithium-ion battery recycling preserves scarce resources, lowers the demand for raw materials, and encourages a more environmentally friendly method of manufacturing and disposing of batteries. These recycling efforts contribute to a circular economy where the battery materials stay in circulation for as long as possible.

How Portable XRF Analysis Aids the Li-Ion Battery Recycling Process

A portable XRF analyzer, such as the Vanta™ series (Figure 3), makes recycling lithium-ion batteries easier by enabling operators to test the elemental composition of samples at different stages of the battery recycling process. Providing results on the spot, the Vanta analyzer can identify the elemental content and metals of the Li-ion batteries, such as lithium (Li), cobalt (Co), and nickel (Ni), during the disassembly and material separation process, as well as during the precipitation process. This analysis makes it possible to quickly separate and classify different battery types for proper recycling processes.

Figure 3. Vanta handheld XRF analyzer

The Vanta handheld XRF analyzer can also identify impurities such as lead (Pb) or mercury (Hg) that are harmful to the health of consumers and the environment. Vanta analyzers provide pass/fail results and low detection limits for regulated elements to make compliance screening easy. The optional capabilities of a camera and wireless connectivity streamlines the data archiving process. As a result, Vanta analyzers are useful tools to evaluate the quality and purity of used Li-ion battery waste in compliance with regulations and standards. Battery recycling operations can improve productivity, advance sustainability, and aid efficient waste management by using portable XRF in their process.

Portable XRF Results for a Lithium-Ion Battery Waste Sample

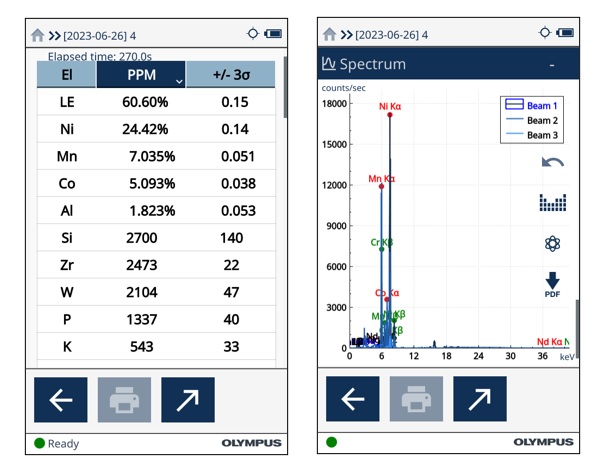

Figures 4 shows the XRF result of a Li-ion battery waste sample (black mass) using the Vanta analyzer. The result demonstrates how the Vanta analyzer can analyze metals such as nickel (Ni), cobalt (Co), aluminum (Al), and manganese (Mn) in the black mass.

Figure 4. Chemistry results and spectrum for a Li-ion battery waste sample (black mass)

This nondestructive analysis provides fast and accurate results with minimal sample preparation. Featuring an intuitive user interface and customizable software, the Vanta analyzer is easy to use and learn for high-throughput testing and enhanced productivity.

*Evident is dedicated to making people’s lives healthier and safer. We are committed to responsibly doing business and serving our markets in alignment with the Guiding Principles on Business and Human Rights set forth by the United Nations.