Ink-jet paper

1. Application

In ink-jet printing, color is fixed through the penetration of ink into paper. Ink droplets are absorbed into the pores of the paper but, in some instances, this can lead to ink bleeding. To create the highest quality image possible, manufacturers create paper that minimizes bleeding. Coated paper, which is widely used for ink-jet printing, absorbs ink both on the coat layer and on the paper beneath, facilitating fine dot size control, good color development, and beautiful reproduction of fine lines. Coated paper is widely used for professional-quality leaflets and other fine documents. Glossy paper used for ink-jet printing is characterized by a smooth surface and is suitable for applications such as photo prints. The condition of the fibers and the surface profile (roughness) of the coat layer in these kinds of paper significantly impact printing quality. Consequently, manufacturers must measure the surface roughness of their paper to ensure they are producing a high-quality product. Conventional roughness measurement methods, such as a contact stylus, can damage paper making it difficult to assess roughness.

2. Olympus' solution

The Olympus LEXT 3D scanning laser microscope uses a non-contact stylus to obtain high-resolution, high-precision 3D surface profile measurements. The LEXT enables users to observe irregularities and measure the roughness of paper’s surface. The microscope’s confocal optical system produces clear 2D images so users can clearly observe entwined paper fibers or the condition of a coated surface. The microscope’s film thickness function is effective for observing a sectional image or micro irregularities on a smooth surface.

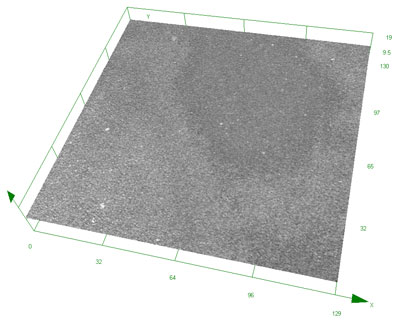

Coated paper

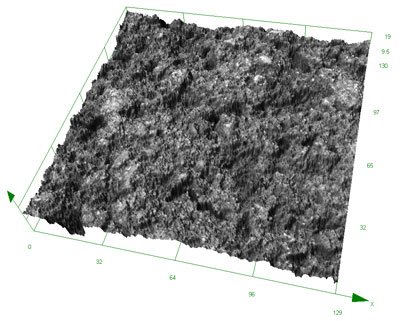

| Glossy paper

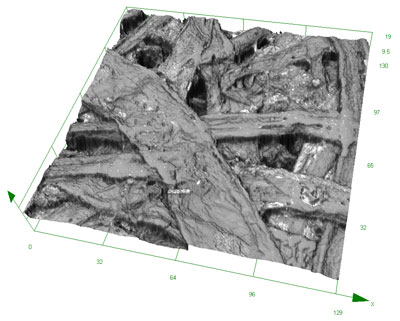

| Regular paper

|