Microscopic shape measurement using a laser microscope

Embossed carrier tape

1. Application

Embossed carrier tape is used for packing various small electronic components used in cell phones and precision equipment. During the embossing process, recesses (pockets) are shaped on the surface of a thin paper or plastic tape. Components are then individually placed into the hundreds or even millions of pockets, sealed with a cover tape, and then wound onto a reel. The packed components on the reel are installed into a surface mounter to affix the components contained in the tape pockets to a substrate. The advantage of this system is that minute parts, such as microscopic ceramic capacitors, integrated circuit (IC) chips, and connectors, can be conveyed in large quantities without being damaged. In addition, the mounting speed using the tape is faster than older methods, such as using hard trays. Managing the dimensions of the pockets is important to prevent the sealed components from rotating in the pockets and to help ensure they come out smoothly when unpacked. As equipment becomes smaller, the components also become smaller, and greater precision is needed to measure the dimensions of the pockets.

2. The Olympus solution

Olympus' LEXT 3D scanning laser microscope uses a 405 nm semiconductor laser and a confocal optical system to capture the focused reflected light. The microscope can also combine multiple images captured at different Z-levels to create clear, high-resolution images and render accurate 3D shapes, even for objects with depth, such as pockets on carrier tape. The microscope’s stitching feature makes it easy to combine multiple images, enabling you to quickly and easily capture a shape

with a wide field of view while maintaining high resolution.

Images

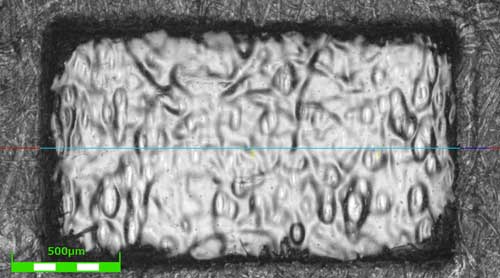

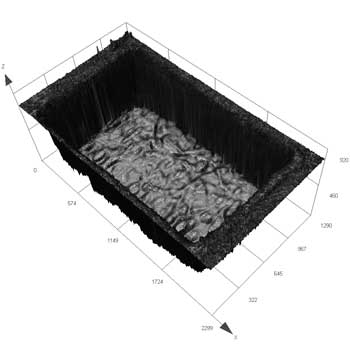

(1) The 3D shape of a carrier tape pocket

|  |

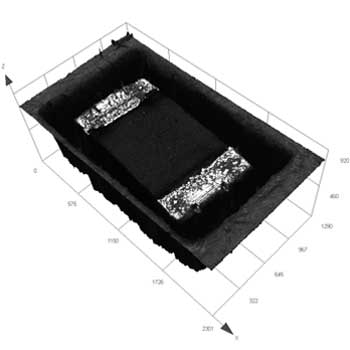

(2) The profile measurement of a carrier tape pocket

|

|