Micron-area shape measurement using a laser microscope

![]()

Coffee cream single-serve cup

Application

Many people put cream or syrup in their coffee at home or when eating out. Some of these liquids are packaged in small, single-serve plastic cups. Before they are filled, the stacked cups are taken out one by one and then filled with the liquid. When stacked cups are taken out by a machine, each cup must be easily removed from the stack to facilitate the filling process. Measuring the surface roughness of the convex area of the cup that makes direct contact with the next cup in the stack is important to help ensure that each cup is easily removed by the machine. If the surface is too rough, the cups may get stuck together.

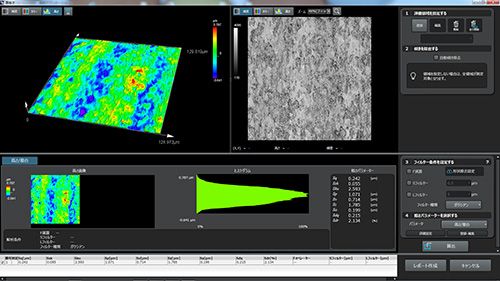

The Olympus solution

Olympus' LEXT 3D laser scanning microscope makes it easy to capture 3D shape measurements with high resolution and high precision, enabling accurate profile measurement of the roughness of a surface and the depth (or height) of surface irregularities. The LEXT microscope provides the same roughness (two-dimensional) parameters as contact-type microscopes do, providing measurement results that are compatible with contact microscopes. The LEXT microscope also provides three-dimensional roughness parameters that comply with ISO25178, providing more information than line roughness through surface-area evaluation using 3D images as well as numerical data. It would be difficult for conventional contact-type microscopes accurately measure the cups because it is difficult to place the stylus on the top of the corrugated and chamfered container. Scanning electron microscopes, primarily used for observation, require a metal layer to be deposited and have difficulty evaluating roughness quantitatively. These challenging issues are solved by the LEXT microscope, which enables non-contact measurement at low to high magnification without losing sight of the small area to be measured and without the need for deposition.