As a part of its eddy current array solutions, Olympus proposes an innovative pipe inspection kit for stress corrosion cracking detection.

Though the results are comparable, ECA technology is much less time-consuming and labor-intensive than penetrant or magnetic-particle inspection. With ECA inspection, you can eliminate costly and complicated procedures, such as paint and coating removal.

The new versitile ECA probe with interchangeable wedges fits a wide-range of pipe sizes.

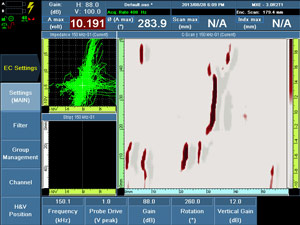

With the new continuous mode, scan imagery is revealed in real time with a constant results stream.

Features

- Efficient inspection on magnetic and non-magnetic alloys.

- Indications are detected in all directions with only a single pass.

- No need to remove paint; fewer steps means time-savings.

- The 32-coil probe provides a large area of coverage.

- Defect depth evaluation capability.

- Continuous mode provides interrruption-free scan imagery.

- Imagery and archiving enabled.

- Adjustable sensitivity and post-process analysis.

- Green method ( no chemicals involved)

Replace Conventional NDT Methods with Eddy Current Array Technology

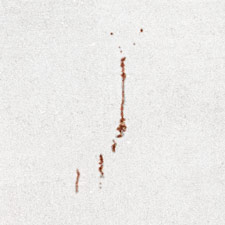

Red dye penetrant indications |

Eddy current array indications with red dye color palette (patent rights protected) |

Pipe Inspection Kit

| ||

|  |  |

The pipe inspection kit includes 15 wedges for pipe sizes from 33.4 mm (1.310 in.) and up.

Adaptable to Part Geometry

When a part changes shape, Olympus wedges can adapt.

1. Select the wedge you need. |

2. Slide the wedge into the slot. | |

3. Apply the flexible probe to the wedge. |

4. The probe is now ready to use |