|

Fiberglass reinforced plastic (FRP) is used extensively in the boating industry for both work boats and recreational craft. Boat manufacturers and marine surveyors need to obtain accurate hull thickness measurements. In the past, unless there was a place to put a micrometer, there was no way to determine thickness except to drill a hole in the hull. Today, modern ultrasonic thickness gauges make it easy to check the thickness of boat hulls.

|

Equipment Used for Fiberglass Thickness Measurements of Boat Hulls

The 39DL PLUS™ and 45MG thickness gauges with the High Penetration software option are capable of making digital thickness measurements on fiberglass. They are commonly used with an M2008 transducer (500 kHz) to maximize the penetration of ultrasound in thick or attenuating fiberglass, providing an approximate thickness measurement range of 0.15 in. to 3 in. (4 mm to 75 mm), depending on the type of fiberglass.

In especially challenging cases, the 39DL PLUS thickness gauge with the high penetration transducer option and large waveform display is recommended. This configuration enables operators to adjust setup parameters on-site. Transducers such as the M1036 (2.25 MHz) or M109 (5 MHz) can measure down to approximately 0.05 in. (1.25 mm) in fiberglass.

Procedure for Measuring Fiberglass Hull Thickness

The 39DL PLUS and 45MG thickness gauges with the High Penetration option both have pre-programmed default setups for the two transducers commonly used for fiberglass measurement: the M2008 and M1036. In many cases, these default setups can be used with no further adjustment, just the two-point velocity and zero calibration that is recommended for all ultrasonic thickness measurements.

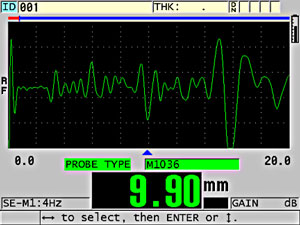

The fiberglass used in boat construction is generally of high quality. Unlike some other fiberglass laminates, it usually does not produce high amplitude internal reflections that can cause false readings. However, if false readings are observed in a particular case, the situation can usually be corrected by small adjustments of the initial gain and TDG slope as outlined in the gauge operating manuals. The 39DL PLUS thickness gauge waveforms below show a typical hang up on internal reflections

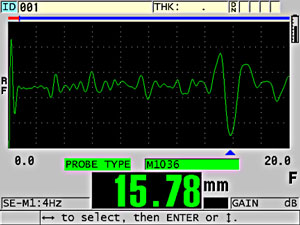

and a correct reading of total hull thickness following a simple gain adjustment.

False reading due to a hang up on internal reflections

Correct reading following gain adjustment

Any delaminations that may occur in the hull will appear as strong, well-defined reflectors accompanied by a complete loss of the back wall echo. While ultrasonic flaw detection should always be performed with instruments specifically designed for that purpose, such as the EPOCH™ series, a trained operator can use the waveform display of the 39DL PLUS and 45MG gauges to make initial judgments about the presence of delaminations in a hull.

Gelcoat measurement: A closely related application is measuring the smooth gelcoat applied over fiberglass. For detailed information on ultrasonic measurement of gelcoat thickness, please refer to our application note, Measurement of Fiberglass Gelcoat.