Heavy Duty Stages

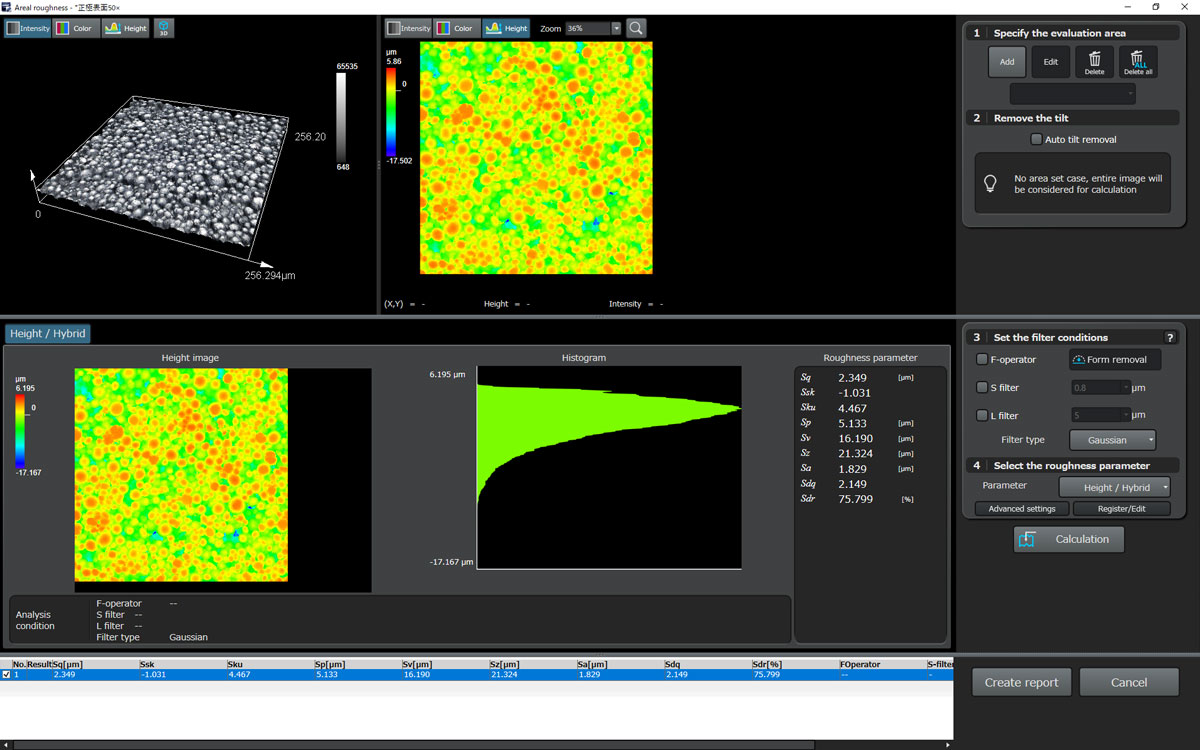

OLS5100-TM Laser Scanning Microscope—Achieve Nanometer-Scale Measurements of Large Samples

The OLS5100 microscope has multiple customization options to enable nm-scale measurements from large electronics such as silicon wafers and PCBs, as well as heavy components including automotive parts. These options include:

- Motorized stages of up to 300 × 300 mm for the inspection of large and heavy samples

- Stages with higher load capacity of up to 30 kg

- Manual Z-movement for easy measurement of samples of different heights

Download Brochure |

Large Bridge Stands

Large Bridge Stand—High Stability for Extra-Large Sample Measurement

Stability is a key factor for high-resolution inspection of components such as silicon wafers, electronics, or large automobile parts. The customizable large bridge stand is designed to ensure the precision and accuracy of measurements taken with the OLS5100 microscope. Features include:

- Vibration-damping properties of granite to provide exceptional stability

- Motorized stages up to 400 × 400 mm enable inspection of large samples up to 20 kg in mass

- Manual Z-drive of 150 mm increases the number of large and tall objects that can be inspected

Download Brochure |

|

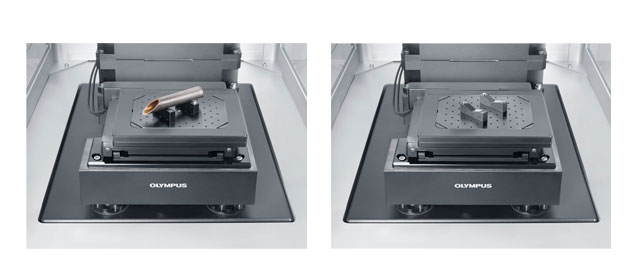

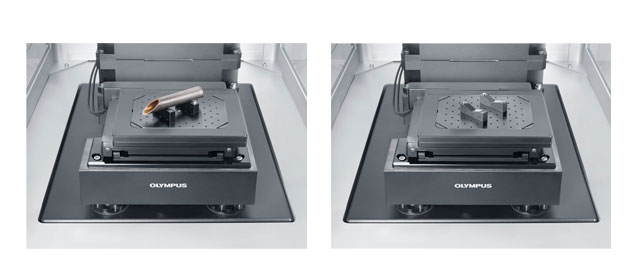

High-Stability Workstations

High-Stability Customizable Workstations–Maximizing Measurement Precision

Achieving optimal measurement precision during nm scale inspection of samples such as electronics requires equipment that can minimize the effect of external vibrations.

Our high-stability workstations enable precision nm-scale inspection. The workstations include:

- Stable microscope stands

- Active antivibration units―integrated or desktop

- Environmental control boxes

- Separate stands for PCs and monitors to eliminate vibration from the PC to the microscope.

These workstation components can used to customize a complete turnkey solution or purchased individually based on your requirements.

Download Brochure |

|

Stable Stone Top Stand

Stable Stone Top Stand—Optimized Working Environment

Achieving suitable environmental conditions for optimal precision when conducting nm-scale inspection of electronics or other objects can be challenging.

The stone top stand helps ensure operators can obtain reliable measurements in high resolution.

- Designed for the OLS51000 CUS TM microscope to provide high microscope stability during inspection of bulky and heavy objects

- Leveling feet enable easy height adjustment of 0−50 mm for uneven surfaces

- The stainless-steel frame and a scratch-resistant tabletop protects against damage

Active antivibration units may be integrated seamlessly into the microscope stand―a highly compact solution―or fitted with an antivibration desktop unit depending on your inspection needs.

|

|

Active Antivibration Desktop Unit

Active Antivibration Desktop Unit—Eliminate Small Vibrations for Higher Precision

For applications that require nm-scale resolution, such as wafer inspection, even light footsteps or minor noise can affect measurement accuracy.

The active antivibration desktop unit is designed to eliminate external vibrations and has multiple features that increase stability and measurement precision:

- Active bandwidth of 0.6−200 Hz

- Isolation performance minimum of 25 dB at 5 Hz or 40 dB at > 10 Hz provides excellent stability

- Load capacity of up to 150 kg, which provides microscope stability during inspection of heavy objects such as automobile parts

|

|

Environmental Control Boxes

Environmental Control Boxes―A Powerful Tool for Cleanroom Inspection

Microscope shielding provides an ambient working environment that enhances measurement accuracy and reduces scanning sound when using the standard LEXT systems. To help users maintain efficient inspection workflows with shielding, the environmental control box has multiple innovative design features:

- Large front and side doors provide easy access to the LEXT EAF, enabling rapid manual Z-movement or height block adjustment and efficient sample placement

- The elegant, streamlined design has transparent windows for workflow monitoring

- The environmental control box protects the LEXT system from dust, making it useful for cleanroom inspection

- The box can be screwed directly to the dedicated table, increasing microscope stability and measurement accuracy

- Compatible with all standard LEXT models

- Similar solution is also available for the larger LEXT OLS5100 CUS TM system

|

|

Custom Fixtures

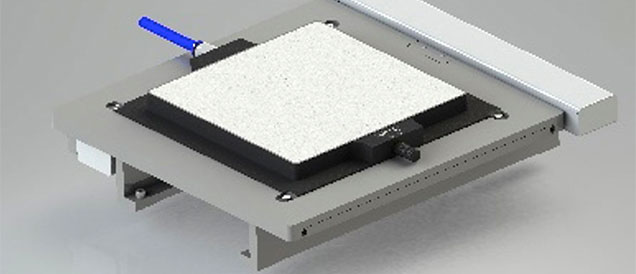

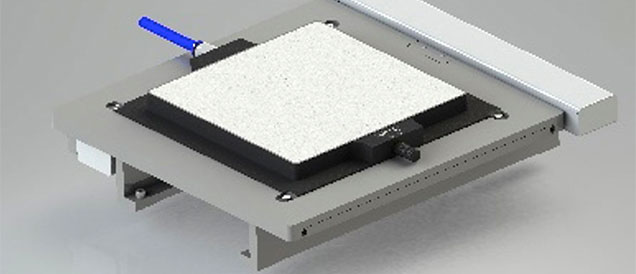

Microporous Vacuum Chuck—Optimal Fixturing for Delicate Samples

Accurate inspection of thin and flexible items such as RFID films, solar panels, and silicon wafers require sample holders that provide even clamping force and minimal sample deformation.

The microporous vacuum chuck maintains the flatness and integrity of delicate samples during inspection. This is achieved using uniform suction via micropores instead of suction holes or grooves.

- Microporous vacuum chuck minimizes sample movement, increasing measurement repeatability

- Specially designed for silicon wafer inspection

- Enables efficient inspection of thin-walled substrates, such as papers, foils, wafers, and PCB boards

Download Brochure |

|

Rotatable Vacuum Wafer Holder

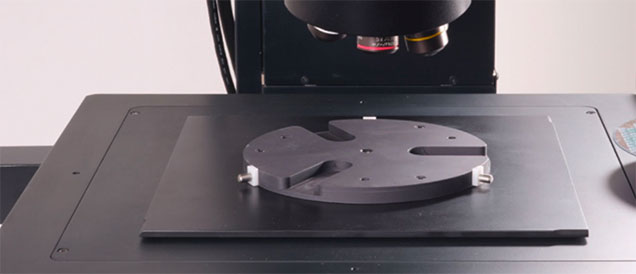

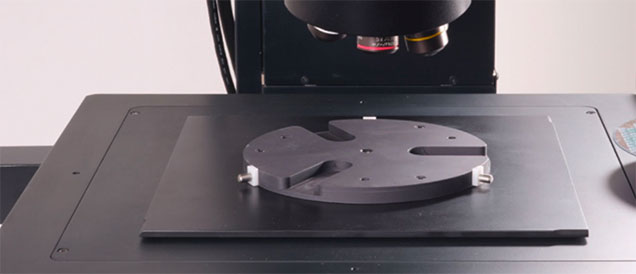

Rotatable Vacuum Wafer Holder—Stable and Secure Wafer Fixture

Sample holders must provide easy sample navigation and stable fixturing to ensure efficient silicon wafer inspection.

The vacuum wafer holder has multiple features that streamline wafer inspection workflows:

- Uniformly distributed vacuum force for maximum wafer stability and optimal measurement accuracy

- Rotation of wafers makes sample navigation easier and faster

- Stepped design with 30 mm wide grooves for convenient sample placement

- Holder can be fixed directly onto a 300 mm stage, or onto a 200 mm stage using an adaptor plate

- Designed for inspection of 4 in., 6 in., 8 in., and 12 in. wafers

|

|

Rotatable Wafer Holder

Rotatable Wafer Holder—Streamlined Wafer Inspection

The rotatable wafer holder provides a straightforward and economic alternative for sample fixation where vacuum suction is not required.

- Rotation of wafers improves sample navigation and speeds up inspection

- Stepped design with 30 mm wide grooves simplifies sample placement

- Holder can accommodate 4 in., 6 in., and 8 in. wafers

- We also offer a dedicated 8 in. wafer holder for DSX microscopes

|

|

Screw Hole Fixtures

Screw Hole Fixtures —Easy Inspection with Custom Fixtures

Custom fixtures are often required to hold pipes, cubes, or other irregular objects during inspection.

Featuring 68 uniformly distributed M3 thread holes and measuring 150 mm × 110 mm × 5.5 mm, the insert with screw holes can accommodate a wide variety of custom features for versatile sample fixturing

|

|