|

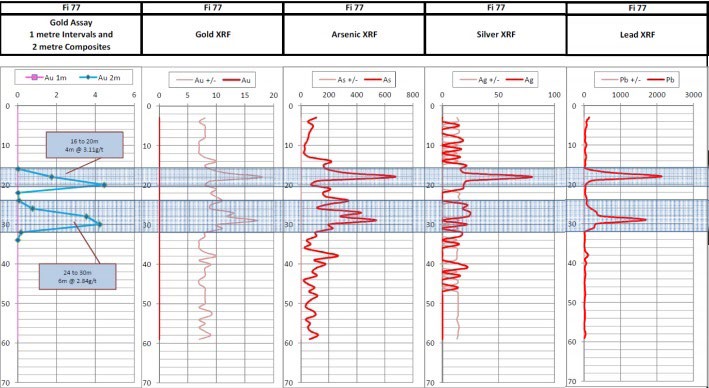

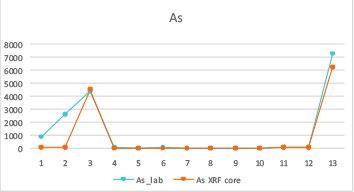

Figure 1. Anomalous Au, As, Ag and Pb measured by XRF from within the Au bearing zone at a Rimfire Resources exploration project in NSW, Australia |

VantaTM handheld X-ray fluorescence (XRF) analyzers provide convenient, easy, on-the-spot measurements of drill cuttings and core to obtain fast field geochemistry results.

Return on Investment

Use of handheld XRF analyzers for exploration drilling can provide a rapid return on investment for certain projects. This translates into direct cost savings to shareholders very quickly. On their projects in the Northern Territory, Australia, Managing Director Darren Holden estimated cost savings of $900,000 AUD in one year directly attributed to using two Olympus XRF analyzers. Savings were made using XRF as a screening tool on RC chips to help select the most important samples for more expensive laboratory analysis.

Drill Core Logging and Optimizing Sample Selection

|

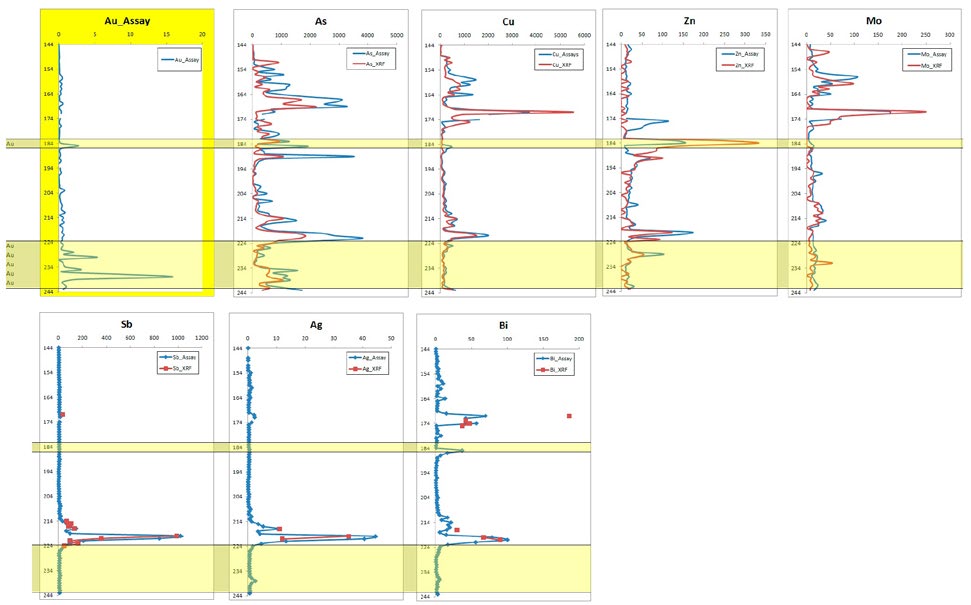

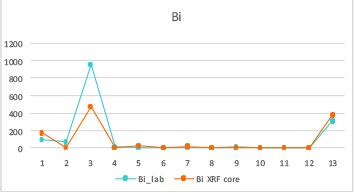

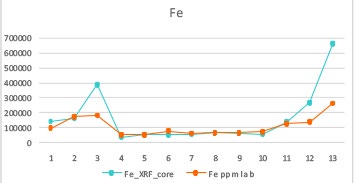

Effective use on freshly drilled or cut diamond core is one of the most difficult applications for XRF due to the veiny and spotty (non-homogenous) nature of geological samples. Nonetheless, methodologies are routinely established to gather XRF data from numerous points per meter of core to assist geologists in selecting samples for lab analysis and to provide supplementary and immediate geochemical data during core logging. This is generally a qualitative/ semi-quantitative use of

XRF to identify trends within the geological system. In the three graphs opposite from a Cu exploration project in the Iberian Pyrite Belt, XRF readings were taken every 10 cm and averaged over each meter and compared with lab data. Trends can clearly be seen suggesting samples 1–5 and 10–13 be selected for lab analysis. It can be argued that it is unnecessary to send samples 6–9 to the laboratory, potentially saving 30% of your lab costs within this sample subset.

This is an example of an actual orientation survey on a customer project.

|  |

|  |