Commercial airlines have tight timelines to meet. But this can only be done if aviation inspections stay on schedule—and that starts by equipping your team with the right videoscope or borescope solution.

Read on to explore three reasons to add a working channel scope to your inspection toolbox.

1. Quickly retrieve foreign object debris with highly flexible tools.

At any moment, small objects such as nuts and bolts can fall in an engine during an aviation inspection. These unwanted objects are generally known as foreign object debris (FOD)—and commercial aviation inspectors need to retrieve them as soon as possible.

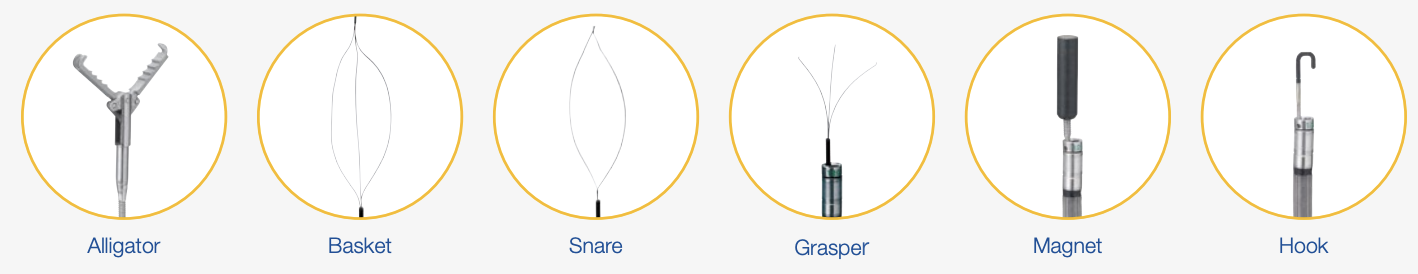

With a working channel scope at the ready, you can easily retrieve the foreign object. Versatile inspection solutions like our new Working Channel Scope for the IPLEX™ NX industrial videoscope come with six handy retrieval tools—an alligator clip, snare, basket, grasper, magnet, and hook.

Two popular tools are the magnet and hook. The magnet tool is useful for capturing the FOD of magnetic materials. Simply bring the magnet close to an object to securely pick up and retrieve it. You can see how this works in the video below:

The magnet tool retrieves the FOD

The snare has a wire loop, which you can use like a lasso to catch bolts and extract them from the engine. Once you loop around the bolt, all you need to do is pull on the wire to cinch it and securely extract the bolt.

2. Access a fast RVI backup if your standard scope goes down.

Aircraft engines are hostile environments for insertion tools, which must go in tight areas with hard edges made of steel and ceramic.

The reality is, your standard inspection scope will experience wear and tear over time. The longer you use it, the higher chance it could go down. If you’re in the middle of an inspection and your scope breaks, it would be a worst-case scenario if you don’t have a backup.

So, what can you do? Just take out a working channel scope.

Even though working channel scopes are often seen as specialty items—a tool you only use for FOD retrieval or channel operation—they can be used for standard visual inspections as well.

Not only does it behave the same as a standard insertion scope, but a working channel scope is often in better condition since inspectors typically don’t use it as often. You can even use it for both normal and special inspection tasks to keep costs down.

3. Work efficiently with ergonomic features.

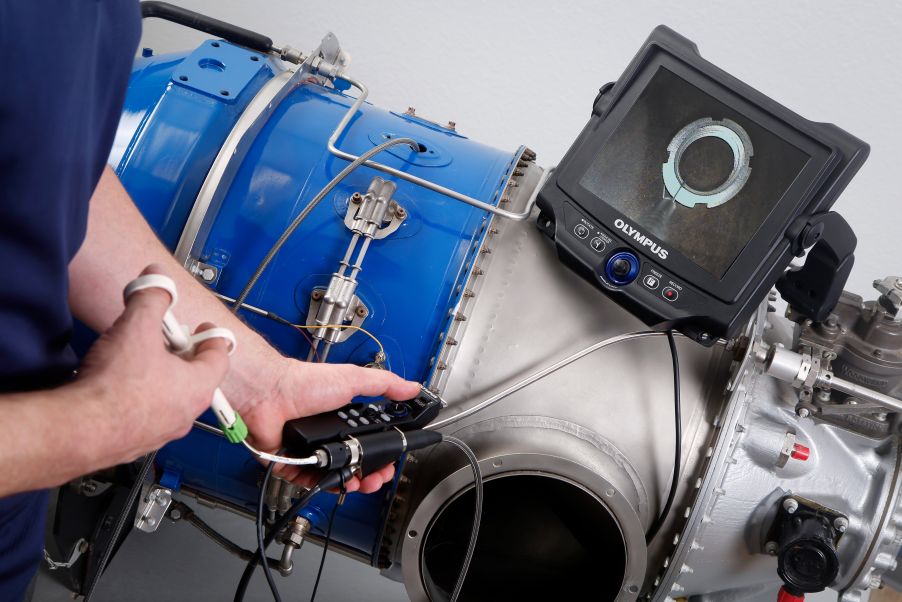

Aviation inspectors need to operate scopes in tight spots, so it’s critical their equipment is as ergonomic as possible. The problem is, performing inspections with conventional working channel scopes can feel like a balancing act since there are so many components to operate.

To illustrate, here’s what FOD removal with a conventional scope looks like:

In the right hand, the inspector holds the retrieval tool actuator. In the left one, they move the insertion tube around the inspection area. With one of their two hands, they need to operate the screen to take images. But, how? The inspector doesn't have enough hands.

With the correct tool, both efficiency and productivity can be improved significantly.

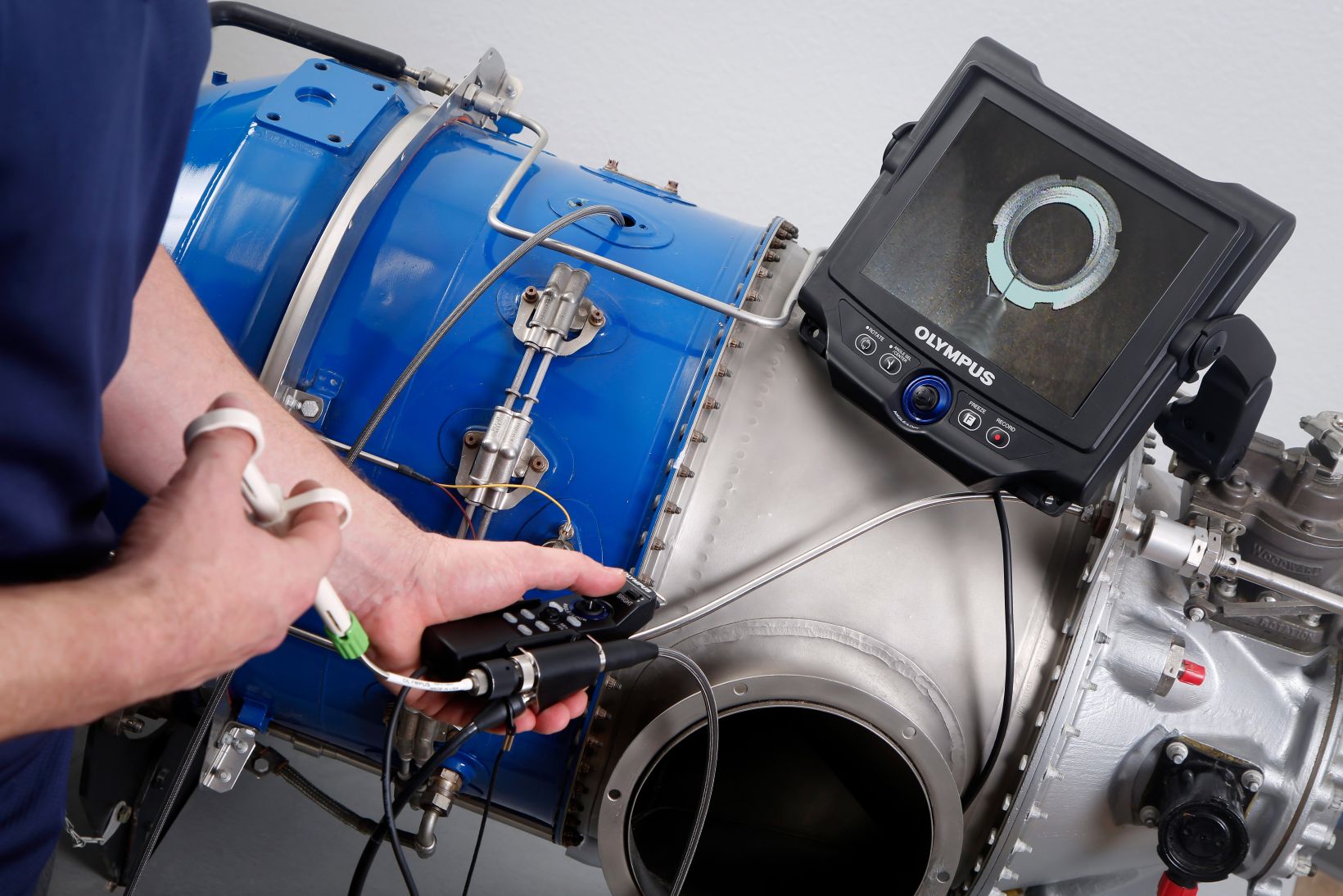

For instance, modern working channel scopes offer features that give inspectors more comfort and control. Our Working Channel Scope for the IPLEX NX videoscope has a large LCD screen you can easily see and detach to hang where it’s most convenient. It also comes with a lightweight remote so you can control the screen from a comfortable position.

The Olympus Working Channel Scope for the IPLEX NX videoscope offers comfort and ergonomics so you can focus on your work.

The remote is also conveniently attached to the actuator. With the actuator and remote in one hand, you can quickly switch between them while manipulating the insertion tube in the other. This modern setup can help reduce wrist fatigue as well as increase inspection efficiency.

Related Content

Application Note: Visual Inspections of Commercial Jet Engines

Brochure: Working Channel Scope

Get In Touch