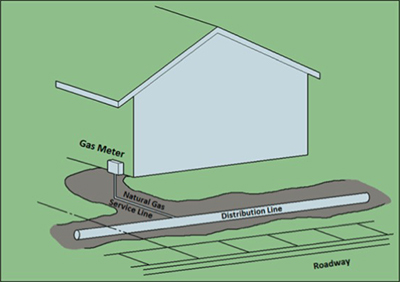

Natural gas pipelines transport more than 25% of the energy consumed in the United States, making them an important component of energy transportation systems. Service lines connect the distribution line, which runs parallel to the road, with the gas meter on a property. Older service lines can potentially corrode, resulting in natural gas leaks in residential areas. Gas leaks can have damaging consequences, so service lines must be regularly inspected to ensure continuing safety. If your home has natural gas, you may wonder how inspectors monitor the integrity of natural gas pipelines. Nondestructive testing (NDT) methods are an essential tool for natural gas line safety inspectors because they enable inspections without risking the integrity of the pipeline. Using remote visual inspection (RVI) instruments, safety inspectors can evaluate the status of a natural gas service line. |

|

New Material, New Inspection Challenges

Plastic pipelines are currently replacing the older cast iron ones initially used to transport natural gas. Although plastic is a safer alternative to cast iron because it’s less susceptible to corrosion, plastic service lines create a new set of challenges for safety inspectors.

The fittings on plastic service lines are welded by heat fusion, which can create large weld joints in the interior of the pipe. These large joints reduce the interior diameter (ID) at the bands, preventing industrial videoscopes with large diameter insertion tubes from fitting through the pipe.

What Gas Line Inspectors Look for in a Videoscope

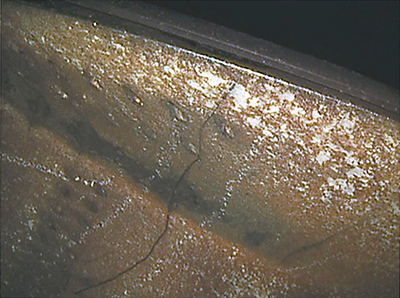

RVI videoscopes used in service line inspections must have a large focal range to see the interior wall and down the length of the entire pipe for navigation. Small-diameter insertion tubes that are very long are an advantage as they can reach further into service line piping while accommodating for limited access points. The insertion tube and tip must be durable and provide a clear view inside dark spaces. Image clarity is crucial when inspecting a service line for cracks and general signs of wear because missing cracks or other discontinuities compromises the safety inspection of the service line. |

|

Inspection Solutions in the Pipeline

Olympus offers a solution for gas line inspection in our IPLEX™ videoscope series, which includes the following features:

- 30-meter articulating scope with an 8.5 mm (and 6 mm up to 18 mm) diameter to ensure the entire line is inspected—even if the weld joints have a reduced inner diameter (ID)

- TrueFeel® power-assisted mechanical articulation (6 mm scope) and pneumatic articulation (8.5 mm scope) provide reliable maneuverability, even at 30 meters

- LEDs in the scope tip (or a powerful laser located in the base) illuminate the weld area, providing reliable brightness inside the pipe

- Lens cleaning system to remove fine dust and drip residue on the scope tip, ensuring clear images

Whether gas line inspectors require a light, portable videoscope, such as the handheld G Lite videoscope, or the IPLEX YS videoscope with its extra-long insertion tube, Olympus has a range of options to meet their needs. We also offer videoscopes with HD RVI™ for extreme clarity, helping inspectors spot corrosion or cracking in a natural gas service line before problems occur.

Related Content

Natural Gas Service Line Inspection Using Videoscopes

Preventing Pipeline Problems: Inspecting for Corrosion Using a Dual Conventional Transducer

Advancements in Remote Video Measurement: Get More Precision from Farther Away