Phase coherence imaging (PCI), an advanced technique available on our OmniScan™ X4 flaw detector, vastly improves the visualization and characterization capabilities for some of the most historically difficult-to-detect defects using conventional ultrasound techniques. PCI’s imaging enhancements offer improvements not only for these challenging use cases, but also for common use cases such as weld inspections and crack sizing.

Unlike current ultrasonic testing technologies—including conventional phased array (PA) and total focusing method (TFM) techniques—PCI’s signal processing does not consider the amplitude when generating TFM images. It detects defects using only the phase information of the signal by measuring the phase coherence of the elementary A-scans for each point in the TFM zone.

Challenges That PCI Helps Overcome

Sound attenuative and coarse-grained materials

Relying on the signal’s phase rather than the amplitude means that even in materials with high attenuation or background noise, the coherence of the signal can still be evaluated since the frequency distribution can be found even with low signal amplitude.

In fact, the noisier the background noise is, the easier it is for PCI to distinguish between the phase coherence of the flaw signal and the incoherence of the chaotic noise. This is why the results are better in coarse-grained materials such as austenitic steels.

Detecting small defects, especially those near large reflectors

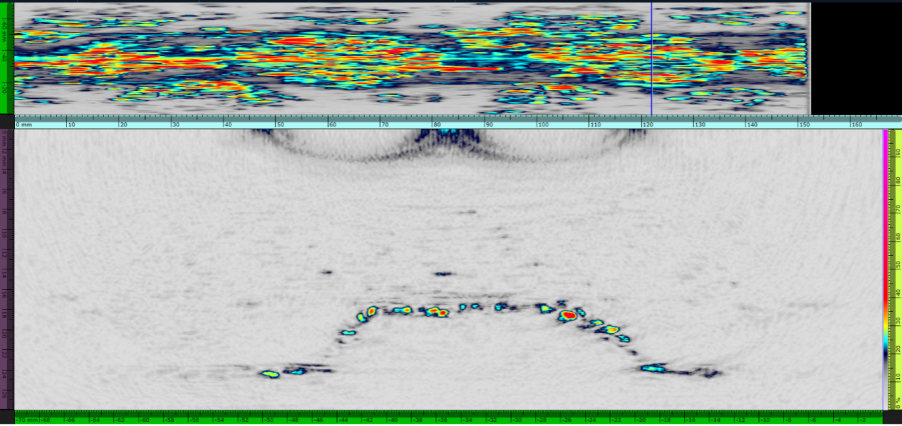

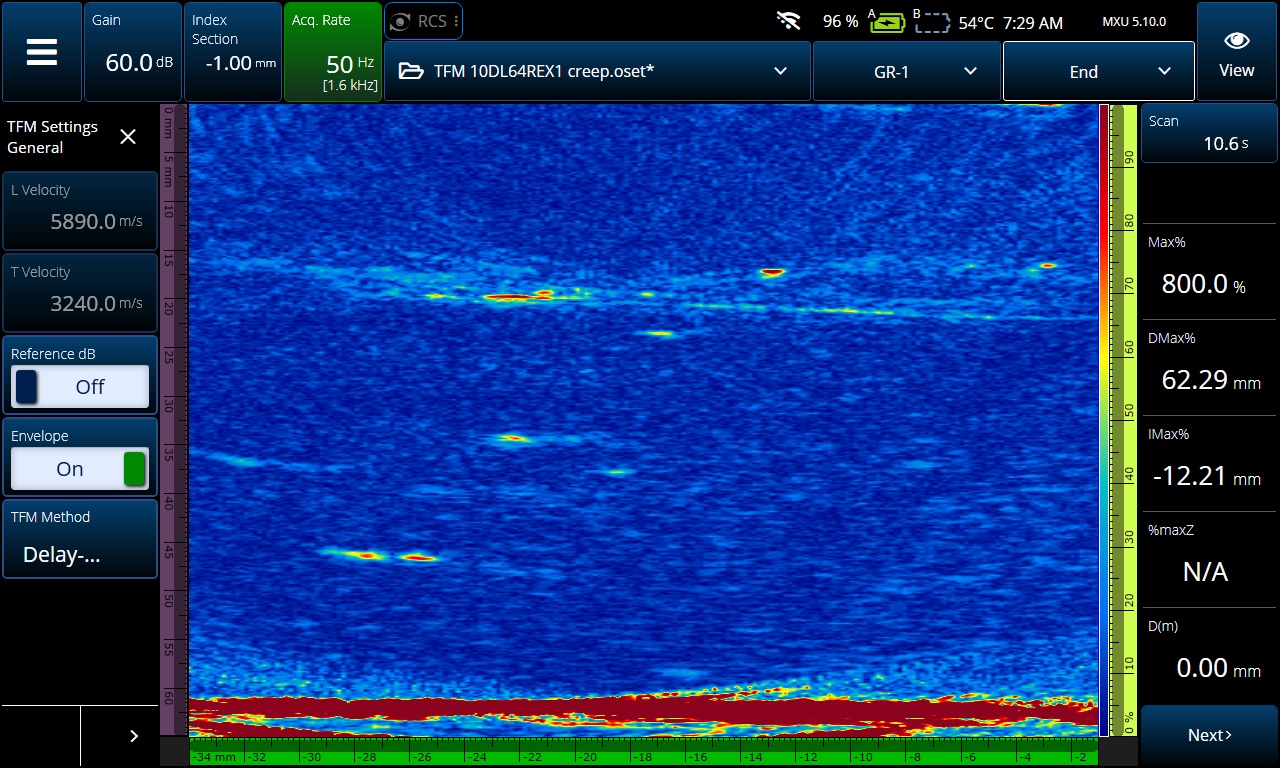

For example, compare this conventional TFM image versus the PCI mode image of creep damage:

The back ground noise and the back wall echo in the amplitude-based TFM image (blue background) obscur the creep damage that is clearly visable in the PCI mode image (gray background). Both images were acquired using a 10 MHz, 64-element Dual Linear Array™ (DLA) probe and the L-L wave set.

Because amplitude is no longer a factor, gain adjustments and signal saturation are also eliminated. This helps mitigate problems such as strong echoes from the back wall or other larger reflectors obscuring smaller defects in their proximity.

Here are 4 use cases where PCI is particularly powerful, but these definitely don’t cover all the possibilities:

1. High-Temperature Hydrogen Attack (HTHA)

High-temperature hydrogen attack (HTHA) is a damage mechanism that is very difficult to detect using amplitude techniques, particularly in its early stages. This is due to multiple factors such as the orientation of defects, the size of defects, and their proximity to the back wall.

Since PCI generates TFM images using only the phase information from the elementary A-scans and not the amplitude, HTHA can potentially be detected in its earlier stages. This is because the diffraction response from these small reflectors is highly coherent compared to large specular reflectors such as the back wall. The orientation of the defect is also less important for the same reasons. Since each small “edge” in the defect emits a diffraction signal, the direction and orientation can easily be seen.

HTHA damage imaged using PCI, an imaging mode offered on the OmniScan X4 flaw detector.

PCI has shown to provide better images of early stage HTHA than amplitude-based techniques.

2. Wet Hydrogen Sulfide (H2S) Damage

Hydrogen induced cracking caused by blistering from a hydrogen sulfide (H2S) rich environment creates an interesting challenge for amplitude-based ultrasound inspections. The blisters can be easily seen using a 0-degree inspection with phased array or conventional TFM but determining whether the blister has connected to the surface can be difficult or impossible. This is because the sound is unable to access the surface connections, or the amplitude is not sufficient to determine the extent of the blistering.

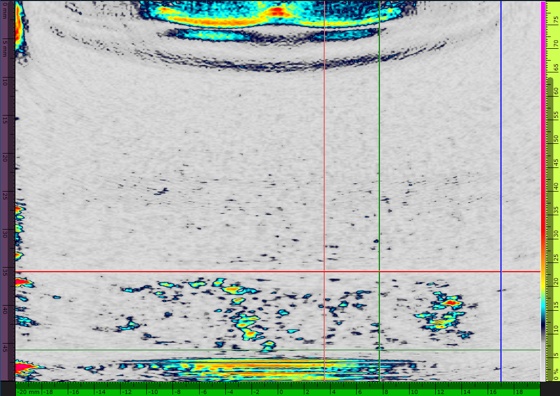

PCI rendering of hydrogen sulfide (H2S) induced blistering. The image displayed in OmniPC™ software was acquired by the OmniScan 64:128PR model flaw detector, a 7.5 MHz, 64-element DLA probe, and the L-L wave set.

These surface connections can be easily seen with PCI because even a weak amplitude return signal. The phase information can still be evaluated despite a weak signal, which reveals this hidden but essential information.

3. Stress Corrosion Cracking (SCC)

PCI’s increased sensitivity to vertical defects compared with conventional TFM is particularly effective for detecting and sizing stress corrosion cracking (SCC). With conventional TFM, vertical defects are often difficult to visualize and self-tandem wave sets are required. If the defect is shown with self-tandem wave sets, often the top and bottom are split between two groups, making it more difficult to characterize the defect. This is because the orientation of these defects results in a weak and inconsistent amplitude response.

On the other hand, PCI reliably detects these vertical irregular defects and they stand out clearly on the display. Furthermore, the best results are typically achieved with pulse-echo T-T and TT-TT propagation modes. This is because the tip diffractions from the sharp direction changes in the crack returns a low amplitude but a highly coherent phase response. These tip diffractions enable you to easily identify the shape and direction of the crack, and you can use the “hot” tips to accurately size them.

With PCI, fewer groups can be used for better quality images in situations where defects like SCC are present. Using fewer groups improves the efficiency of your set up and data collection, and it makes learning how to use PCI much easier, especially for less experienced UT inspectors.

4. Weld Inspection

PCI can be very effective for weld inspections since it combines the advantages of reflected signals—like phased array (PA)—and the tip-diffraction phase information—like TOFD. Another advantage of PCI is that fewer groups are required for the same scan coverage.

For a few types of defects, PCI can facilitate their characterization:

- Sizing is easier.

- Images of defects are closer to their real character.

- Defects are less likely to be split between different groups.

PCI is highly sensitive to edge reflections, giving you an accurate portrait of a flaw for your analysis, and the tip diffraction “hot spots” enable you to easily size a defect such as this weld lack of fusion (LOF).

Lack of fusion:

While lack-of-fusion (LOF) defects can easily be seen using amplitude-based techniques, they often present a challenge for sizing. It is not uncommon for the signal from a lack of fusion to be saturated, which makes sizing impossible. Since it is impossible to saturate the signal with PCI, this is never a problem. It is also faster and easier to size the lack of fusion since the tips create diffractions that can be used as reference points for sizing without having to change the gain or find the 6 dB drop.

Porosity:

Porosity can often be difficult to detect with amplitude-based techniques because the amplitude response is similar to background noise. Because the PCI is more sensitive to small defects, porosity is not only visible, but you can also distinguish and identify the individual pores.

Cracks:

For the same reasons as SCC, PCI is an excellent tool for identifying and sizing cracks when inspecting welds.

These are only a few examples of applications where PCI has provided improved results versus amplitude-based techniques, but its advantages could be extended to other inspections involving noisy or attenuative materials and small flaws.

If you want to know how PCI could improve your inspection processes, contact your local Evident representative for a demo or check out some of the other resources on our website.

Learn more about the OmniScan X4 flaw detector here.

Blog post originally published August 30, 2022, and updated October 21, 2024.

Related Content

5 Main Advantages of Phase Coherence Imaging (PCI)

Frequently Asked Questions (FAQs) about Phase Coherence Imaging