Image Quality

Exquisite Optics and Digital Imaging for Quality Inspections

Olympus history of developing high-quality optics and advanced digital imaging capability have resulted in a record of proven optical quality and microscopes that offer excellent measurement accuracy.

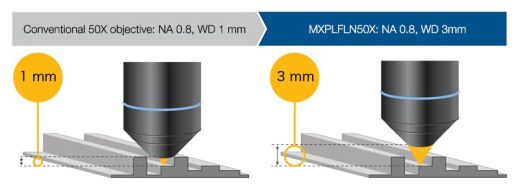

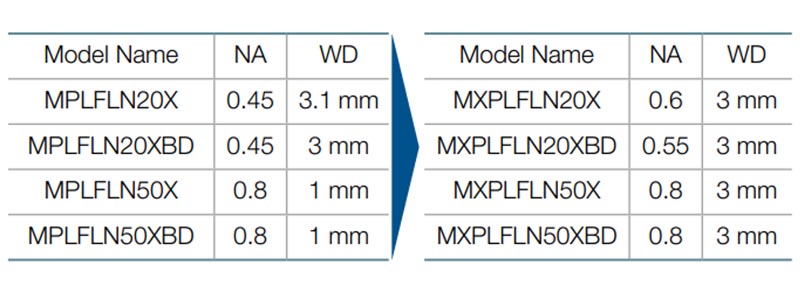

Combined high numerical aperture and long working distance

Objective lenses are crucial to a microscope’s performance. The new MXPLFLN objectives add depth to the MPLFLN series for epi-illumination imaging by maximizing numerical aperture and working distance at the same time. Higher resolutions at 20X and 50X magnifications typically mean shorter working distances, which forces the sample or objective to be retracted during objective exchange. In many cases, the MXPLFLN series’ 3 mm working distance eliminates this problem, enabling faster inspections with less chance of the objective hitting the sample.

|

|

> Learn More about MXPLFLN Objectives

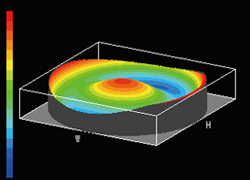

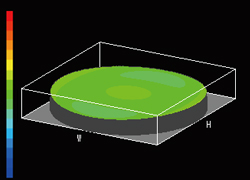

Superior Optical Performance: Wave Front Aberration Control

The optical performance of objective lenses directly impacts the quality of the observation images and analysis results. Olympus UIS2 high-magnification objectives are designed to minimize wavefront aberrations, delivering reliable optical performance.

Bad wave front |

Good wave front (UIS2 objective) |

> Click here for details about UIS2 objective lenses

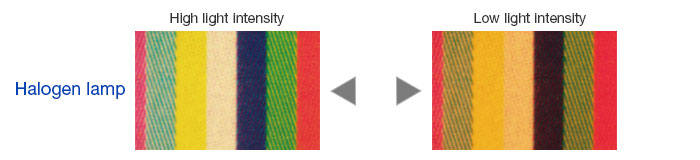

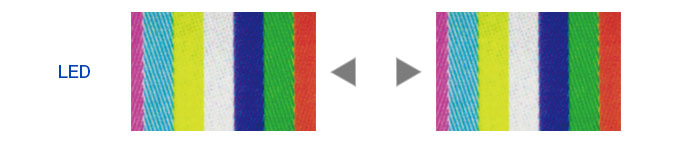

Consistent Color Temperature: High-Intensity White LED Illumination

The MX63 series utilizes a high-intensity white LED light source for reflected and transmitted illumination. The LED maintains a consistent color temperature regardless of intensity for reliable image quality and color reproduction. The LED system provides efficient, long-life illumination that is ideal for materials science applications

Color varies with light intensity.

Color is consistent with light intensity and clearer than halogen lamp.

* All images captured using auto exposure

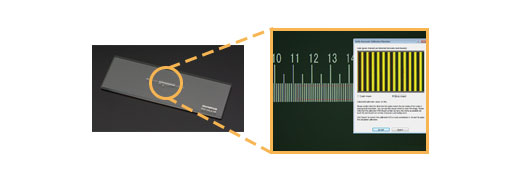

Precise Measurements: Auto Calibration

Similar to digital microscopes, automatic calibration is available when using PRECiV software. Auto calibration helps eliminate human variability in the calibration process, leading to more reliable measurements. Auto calibration uses an algorithm that automatically calculates the correct calibration from an average of multiple measurement points. This minimizes variance introduced by different operators and maintains consistent accuracy, improving reliability for regular verification.

> Learn more about PRECiV software

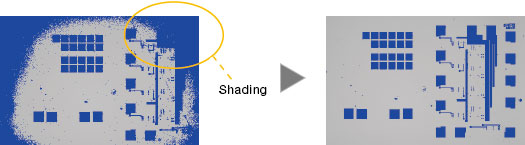

Entirely Clear Image : Image Shading Correction

PRECiV software features shading correction to accommodate for shading around the corners of an image. When used with intensity threshold settings, shading correction provides a more precise analysis.

Semiconductor wafer (Binarized image)

Right image: Shading correction produces even illumination across the field of view.