HVAC and Heat Exchanger Tubing

HVAC and Heat Exchanger Tubing Kit

With this solution, tube inspection is portable, convenient, and simple.

Convenient:

Extra presets are available to increase efficiency and productivity. Spend time fine-tuning rather than configuring.

If you already have probes, you can keep using them; they are compatible with this inspection solution. If you need probes, you can order them from our large selection.

The NORTEC 600D flaw detector comes with a convenient stand that can be used as a carry handle, to rest the instrument on a surface, or hang it from an exchanger or beam to keep it at eye level.

| The footswitch helps free your hands and enables the inspector to clear the screen and null without disturbing the work at hand. |

Simple:

The instrument’s intuitive interface makes using the adaptors easy. Inspectors can learn the system in minutes, not hours.

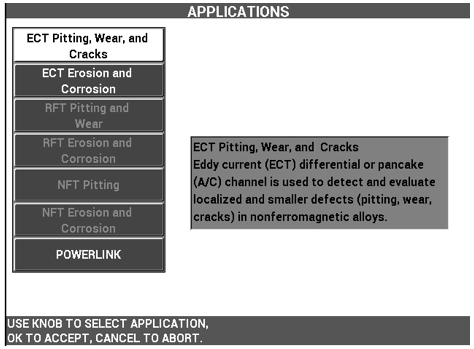

Use this simple chart to select the right adaptor for your application.

| Tube Material and Type | Compatible Magnetic Technology and Adaptors | Compatible Olympus Tube Probe Series | Remarks |

| Non-ferromagnetic (copper, brass, aluminum, titanium, 300 series stainless steel, Inconel®, and others) | Eddy current (ECT) Differential: CBAS-10818-0001 Absolute: CBAS-10818-0001 | TEA/TEB, TEE/TEF, TEG, TEK/TEL | Virtually any bobbin-type probe from Olympus or other manufacturers can be used. |

| Ferromagnetic (carbon steels, nickel) | Remote field (RFT) Differential: CBAS-10821-0001 Absolute: CBAS-10821-0001 | TRS, TRX |

Use single exciter (TRS) for erosion/corrosion.

Use dual exciter (TRX) for pitting. |

| Mildly ferromagnetic (Monel®, 400 series stainless steel, Duplex stainless steel) | Eddy current (ECT) Differential: CBAS-10818-0001 Absolute: CBAS-10818-0001 Remote field (RFT) Differential: CBAS-10821-0001 Absolute: CBAS-10821-0001 | TEO or TRX | Higher frequency TRX dual exciter probes are recommended; they are easier to use and procure. |

| Carbon steel finned tubing (typically finned air-coolers; tubes are wrapped with aluminum fins) | Near field (NFT) Differential: CBAS-10819-0001 Absolute: CBAS-10820-0001 | TRD | RFT will not work because the entire magnetic field is absorbed in the fins. |

| Stainless steel finned tubing (typically with aluminum fins wrapped around the tube) | Eddy current (ECT) Differential: CBAS-10818-0001 Absolute: CBAS-10818-0001 | TEA/TEB, TEE/TEF | Set the frequency high enough (500 kHz) to inspect the internal surface only. No penetration is possible. An alternative is IRIS (ultrasound). |

| Air conditioner (A/C) [chiller or evaporator] finned copper tubing | Eddy current (ECT) Differential: CBAS-10818-0001 Absolute: CBAS-10818-0001 | TEA/TEB, TEC/TED | Regular bobbin probes are often used; however, A/C probes or similar competing models will detect circumferential cracking. |

Advanced Features:

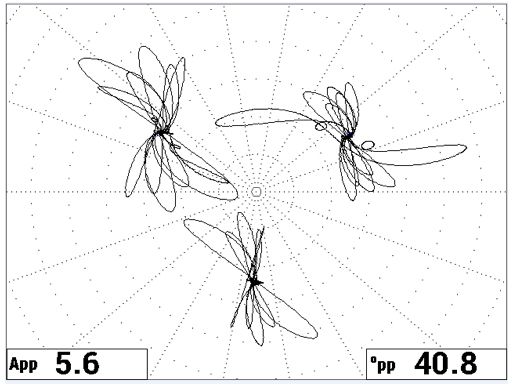

Dual frequency enables detection near support plates using mixing. Mixing is a subtraction process where the support signal is either suppressed or reduced significantly.

Discontinuities can be sized using amplitude and angle readings that are instantly marked on the screen. Discontinuities can be identified easily and rapidly.