Olympus Portable X-ray Fluorescence (pXRF) analysers provide high performance, real-time geochemical data for rapid multi-element characterization of soils, rocks and ores. Recent, major advances in pXRF technology has vastly improved the limits of detection and number of elements measured, in addition to significantly reducing analysis test times. pXRF is now utilized as an effective method for exploring and in the production of nickel laterite mineralisation. It is routinely used in the reconnaissance drilling, trenching, face sampling, stockpile verification and on concentrates products.

Nickel Laterite Geology

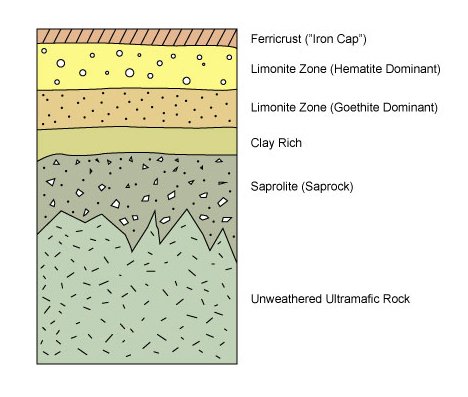

Nickel is found in two key types of deposits; Nickel laterites and magmatic (volcanic) sulphide deposits. Although nickel laterites contain around 70% of nickel reserves, most historical nickel production has come from nickel sulphides.This is changing as nickel sulphide reserves deplete and the worlds consumption of nickel grows steadily each year. Another favourable by-product of mining nickel laterites is their concentration of cobalt, which is specifically valuable due to the rapidly emerging rise of battery metals. Nickel laterites formed through the intense weathering of nickel-bearing ultramafic bedrock, that formed through prolonged chemical and mechanical weathering in wet, warm, tropical environments. Nickel Laterites have long tabular bodies, over several hundred meters, but only tens of meters deep. These deposits consist of a predictable weathering profile that includes five "zones" (below): The un-weathered ultramafic bedrock, the weathered bedrock or "saprolite", a clay-rich layer, limonite zone and a ferricrust or "iron cap". |  |

Figure 1 - A generalized cross section of nickel laterite deposits. Source: https://www.geologyforinvestors.com/nickel-laterites |  A Vanta pXRF analyser being used to sample stockpiles (above) and sample active open cut mine faces in New Caledonia (below) |

The Use Case for pXRF

Due to the shallow, tabular ore body geometry and open cut mining methods employed to extract Nickel Laterites, pXRF can be effectively utilized across the whole mining value chain for most of the key element suite (Ni, Co, Fe, Mn, Mg, Al, Si Cr). Processing and extraction of Nickel Laterites often requires very large-scale acid leaching or roasting in rotating kilns or autoclaves, so blending a constant ore feed is critical to optimizing Ni (and Co) recovery. Consequently, pXRF is often employed from the exploration phase (diamond percussion drilling), grade control during mining (trenching face sampling), Run-Of-Mine (stockpile management blending), as well as for analysing final concentrate grades prior to shipping out to a smelter. |  |

Dealing with Moisture Content

One of the challenges of using pXRF on laterite deposits is dealing with the inherent variability in moisture content when sampling in-situ. Moisture creates variation in the pXRF results as moisture interacts with the X-rays attenuating the signal received back to the detector. This often results in an underestimation or low-bias in the reported results. This bias can be corrected for by generating moisture specific calibration methods or by various drying techniques. This can be as simple as sun-drying the samples in plastic or aluminium containers, using portable propane torch or small, field-portable ovens. |  Field photos showing the various use cases for pXRF on a Nickel Laterite Project: On Diamond Drill Core, Face Sampling, Stockpile Sampling Concentrates in the Laboratory |

Figure 2 – Project specific pXRF calibration data for Nickel Laterite (Saprolite) deposit in New Caledonia.