Aviation Borescopes for Aircraft Inspection

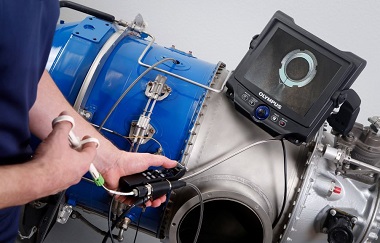

Video Borescopes for Aircraft Engine Inspection and MaintenanceRoutine remote visual inspection is essential for the safe operation of aircraft. Our range of aviation borescopes provides high-quality images with intuitive user interfaces, ergonomic designs, and durability for efficient and effective aircraft visual inspections, jet engine borescope inspections, gas turbine inspections, and helicopter inspections. |

Aviation Borescope Applications

Gas Turbine and Jet Engine Inspection

Aviation gas turbines and jet engines require regular inspection to determine whether any cracks, erosion, or other critical flaws exist. Evident IPLEX aircraft engine borescopes offer outstanding image quality to help you quickly locate indications for faster decision-making and enhanced efficiency. IPLEX video borescope inspections of gas turbines give you a clear view of everything from the large space in a combustion chamber to a closeup of a compressor blade.

IPLEX aviation video borescopes offer powerful measurement features for fast, efficient aircraft engine inspections. Super wide stereo measurement provides expanded coverage, while 3D modeling makes it easy to choose the right measurement point by showing views of your target from multiple angles.

Quickly switch the interchangeable scopes in various diameters and lengths to perform different types of aircraft and jet engine inspections with one IPLEX system. Plus, having spare scopes on hand can help reduce downtime if a scope repair is needed.

One example of a useful alternate scope to have in your toolbox is a channel scope. With capabilities similar to a standard insertion tube, the working channel scope can also be used for foreign object debris (FOD) detection and retrieval. With this scope in your toolbox, you can avoid unnecessary and costly engine removals or teardowns.

Small Aircraft & Helicopter Inspection

Helicopter engines and rotors are difficult to access for inspection as they are located on the upper part of the fuselage. Our ultra-portable IPLEX™ G Lite aviation video borescopes are lightweight and easy to carry for efficient visual inspection of helicopters and small aircraft and their engines.

Our IPLEX G Lite helicopter inspection video borescope is compact and weighs only 1.15 kg (2.5 lb), making it easy to carry for the inspection of engines, rotors, and strap packs on top of the fuselage. Many turboshaft and turboprop engines require an aviation borescope with a 4 mm (0.16 in.) or smaller diameter to fit in the access port to inspect near areas, such as compressor blades, and far areas of the combustion chamber.

Obtain bright, high-quality images at a distance using the IPLEX G Lite video borescope with a 4 mm (0.16 in.) scope. When halation occurs in nearby areas, the video borescope delivers clear images thanks to advanced image processing technology

Aviation Borescopes

Visual Inspection Kits for Aviation Turbines

Our visual inspection kits include IPLEX videoscopes with 3D visual measurement and other recommended tools for high-quality gas turbine inspections. Perform efficient inspections with videoscope accessories, such as:

- J-Shaped Tube: A useful guide tube if you want the scope to reach a location that is against the direction of gravity or to move in a certain direction. The J-shape is optimized for general combustion chamber inspections.

- Flex and Stay Tube: Pliable yet rigid tube that can be freely shaped. Easily bend the tube in any shape to reach an object for remote visual inspection.

- Heat-Resistant Sheath: The sheath minimizes the temperature restrictions placed on standard videoscopes for gas turbine and other applications where high-temperature—as hot as 250 °C (482 °F)—inspection may be required.

Industrial Videoscope FAQs

What is an aviation borescope?

Aviation borescopes, or aviation videoscopes, are visual inspection devices used in the aviation and aerospace industries to inspect the internal components of aircraft and their engines to determine if any cracks or faults exist. Aviation borescopes are used for regular visual inspection for aircraft maintenance to ensure all safety regulations are met.

What aviation borescopes are required for aviation and aerospace inspections?

The aviation borescope needed for aircraft inspections depends on the aircraft and engines being inspected. Our range of aviation borescopes includes options for every aircraft visual inspection need. Whether you need to perform 3D visual measurements or require a small, durable aviation borescope, we have an option for you. Our IPLEX series of aviation borescopes feature interchangeable scopes of various sizes to meet your changing needs.

What are the features and benefits of aviation borescopes?

Aviation borescopes enable efficient visual inspection of aircraft and their components, including aircraft turbines, jet engines, and helicopters. With aviation borescopes, you can easily view the interiors of aircraft components to check for defects or faults without having to disassemble them. This enables the regular inspection of these components to help ensure they are in safe working order and meet all regulations.

What are the challenges of aircraft visual inspection?

The principal challenge of aircraft visual inspection is access to hard-to-reach areas. Aviation borescopes enable easy access to aircraft components without the need for disassembly. We offer aviation borescopes of different diameters, including as small as 4 mm (0.16 in.), to attain internal aircraft components with access points of various sizes

Aviation Borescopes Additional Resources

Caring for the Heart of the Aircraft: Videoscope Inspections Help Enhance Flight Safety |  |

2 Modern Videoscope Capabilities for More Precise Aerospace Inspections | |

3 Reasons to Add a Working Channel Scope to Your RVI ToolboxCommercial airlines have tight timelines to meet. Staying on schedule requires efficient aviation inspections—and that starts by equipping your team with the right videoscope or borescope solution. |

|

Videoscope Solution for Working at Heights When Inspecting the Main Rotors of HelicoptersDuring maintenance of helicopters, inspectors use industrial borescopes to check for any damage or cracks in the strap pack located at the base of the main rotor. Learn more about how video borescopes are used in helicopter inspections here. | |

Borescope Inspection of Helicopter Main Gear BoxesDuring routine helicopter maintenance, inspectors use borescopes to check for any breakage or cracks in the gear or gear carrier of the main. Learn more about helicopter inspections here. |

|

Supporting Military Aircraft Mission Readiness with Fit-for-Service VideoscopesWithin every busy operational maintenance squadron, propulsion shop, and intermediate maintenance facility, military inspection equipment is put through its paces. Learn about how our rugged video borescopes are used here. | |

How to Confirm Videoscope Measurement Points with ConfidenceDiscover how inspectors use 3D modeling to select the correct measurement points for more accurate RVI measurements. |