Support

HSMT-X03 Scanner

Discontinued Products

Loading...

Overview

Manual One-Axis Scanner

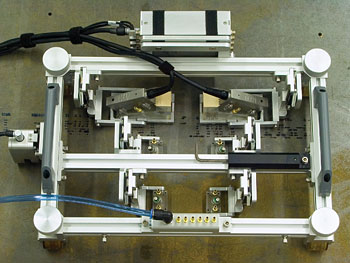

The HSMT-X03 is the construction weld scanner offering the most probe-holding capacity. In fact, the scanner can hold up to 10 probes for either phased array or conventional UT, in order to obtain optimal coverage of the entire weld volume.

The basic configuation is intended for construction welding inspection. In order to be used in more restricted areas, the scanner can also be reconfigured with the provided short frame bars.

Standard inclusions

- Scanner frame with handles, and:

- Three 300 mm (12 in.) frame bars

- Two 200 mm (8 in.) frame bars

- 3 additional 200 mm (8 in.) and two additional 125 mm (5 in.) frame bars allow smaller footprint configuration or inspection on pipes with smaller diameter.

- OmniScan-compatible waterproof spring-loaded wheel encoder with 5 m cable

- Six 90º probe holder brackets

- 6 spring-loaded arms (SLA)

- 6 TOFD-P/E 31.75 mm yokes

- 2 PA 40 mm × 55 mm yokes

- Water manifold

- Irrigation tubing and accessories

Note: Umbilical cable, probes, and wedges are not included with the scanner.

Options

| Specifications

|

Sorry, this page is not available in your country

Let us know what you're looking for by filling out the form below.