The scratch resistance of injection-molded car components plays an important role in a car’s appearance. Confocal microscopy is a fast and highly precise way of quantifying the effect of additives that improve scratch resistance.

Research scientists at Croda International used the Olympus LEXT™ OLS5000 confocal microscope to demonstrate the positive effect of their additives in standardized scratch tests. This approach showed significant improvements in precision, operator variability, and speed. Plastics are used in the production of numerous car components, owing to their versatility, longevity, and low cost. Improvements in the properties of polymeric materials — combined with a drive toward more lightweight materials in cars — have led to increased diversification in the plastics used in automotive manufacturing. Many of these components are clearly visible, meaning that their appearance plays an important role in the aesthetics and value of a car. Scratch-resistant materials help cars retain their value after prolonged use by minimizing the influence of wear and tear on the car’s appearance. The precise composition of a material will determine its scratch resistance, and detailed tests can demonstrate the level of scratch resistance of a specific material. | CrodaCroda International PLC is a leading supplier of migrating additives for improving scratch resistance in plastics. These additives are biobased, plant-derived materials that are mixed with polymers in small amounts, typically up to 1%. After injection molding, these additives accumulate at the surface, forming a thin film that mitigates the effect of scratching. |

Figure 1

Visualization of scratch test data with LEXT software

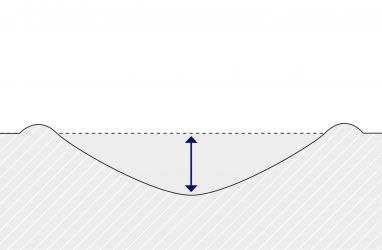

(Figure 2). Martin adds, “The test leaves a scratch and two mounds on either side — similar to a plough going through a field.” After the sample is scratched, the depth, width, and profile of the plaques of material are measured to determine the differences between their compositions. Croda’s original setup used a widefield materials microscope to measure the scratch width and a white-light interferometer to determine the depth by visualizing the scratch profile. However, this approach was highly time-consuming, particularly due to the complexity of setting up the interferometer and analyzing its results. Furthermore, the use of interferometry was also associated with high variability between users and artifacts in the surface profiles. |

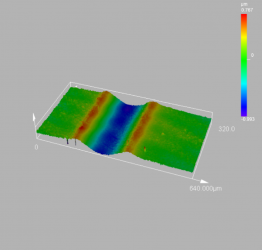

Martin comments: “Because the LEXT™ system can accurately measure in 3D, we could simply view a slice through the scratch and measure depth – much easier” (Figure 4). A key challenge in measuring the scratch depth and profile using interferometry is the presence of spikes in the profile of materials such as polypropylene. These artifacts can interfere with measurements and are the result of the interferometer not detecting the surface. Martin explains: “Because polypropylene has a porous structure, the interferometer does not detect the surface — it looks straight through.” When the same samples were measured using the LEXT microscope, researchers were able to obtain a smoother image of the scratched surface that provides an accurate representation of the scratch and facilitates measurement (figure 4). Fast, Accurate MeasurementsWhen it comes to the speed of imaging, measurement, and analysis, the improvements were even more significant. Researchers at Croda found that by using the LEXT OLS5000 microscope for both scratch width and depth measurements, they could carry out their inspections between 10 and 100 times faster compared to interferometry. “To measure a scratch, we had to set up the interferometer as coarse as it can do,” Martin says, “and setting that up is extremely difficult. It takes about an hour to get one measurement. With confocal microscopy, we could measure and process 10 scratches on a plastic surface in 2 minutes.” | “Seeing how fast the Olympus microscope is, it’s almost annoying to think how much time I’ve spent using the old system.” Dimitris Vgenopoulos, Applications Scientist Variability between operators is also a key challenge for interferometry. As Martin points out, “With the old technique, all four people in our department could get a different result from the same sample.” The LEXT OLS5000 microscope’s automated methods for measuring and analyzing a sample reduce the risk of human errors by making the workflow easier and more standardized. |

SummaryScratch-resistant additives improve a car’s aesthetics and ensure that it retains its value longer. Precise measurements in scratch tests provide a means of reliably validating the positive effect of these additives. Croda’s original approach for scratch measurements, based on optical microscopy and interferometry, was highly timeconsuming and associated with artifacts in surface profiles. By using the Olympus LEXT OLS5000 confocal microscope, researchers at Croda were able to make their measurements more precise and reduce operator variability compared to optical microscopy and interferometry. They also managed to carry out measurements between 10 and 100 times faster, which means that the LEXT microscope improved both inspection efficiency and data quality. | AuthorMarkus Fabich |