OmniScan MX ECA/ECT

概述

OmniScan MX

OmniScan MX

经过现场验证的、可靠的仪器

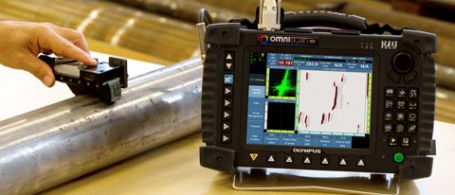

OmniScan MX是一款已经现场验证、性能可靠的仪器,其机身结构坚固耐用,可以在严酷、恶劣的检测环境中正常工作;现在世界上正在使用的OmniScan MX仪器有成千上万台。这款仪器紧凑、轻巧,使用两节锂离子电池供电,在电池满电量时,可以进行长达6小时的手动或半自动检测。

OmniScan MX仪器的8.4英寸显示屏可以实时显示高清彩色图像,在大多数光线条件下,操作人员都可以查看缺陷及其细微情况。用户可使用飞梭旋钮和功能键在仪器简洁、直观的界面上轻松浏览,也可以将USB鼠标连接到仪器,方便对检测数据进行分析。

一个平台、两款模块、三种技术:灵活适用性更强

为了满足更广泛应用的要求,两款模块都提供涡流检测(ECT)、涡流阵列(ECA)以及粘接检测(BT)C扫描技术。两款模块都与MXE(ECT/ECA)和MXB(BT C扫描)软件兼容;要做到这点,只需在各种技术之间进行简单转换,操作人员接受少许培训即可。

|  |  | ||

| 常规ECT | 涡流阵列 | 粘接检测C扫描 | |

ECT4模块 | √ | 不被支持 | √ | |

ECA4-32模块 | √ | √ | √ | |

支持大多数Nortec探头 | 支持32个机载通道;使用外置多路转换器时,可支持64个通道 | 要求使用特殊适配器和扫查器 |

ECA与ECT别无二致

覆盖范围广,扫查速度快,检出概率高

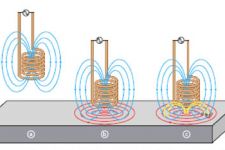

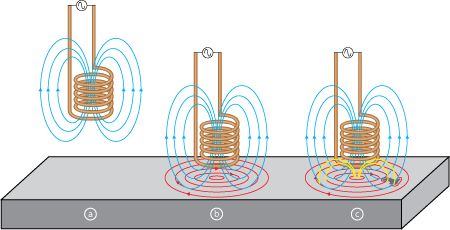

涡流阵列 (ECA) 技术融合了多种传统的桥式或反射式(驱动器-拾波器)探头线圈,以便在一次扫查检测中覆盖更大的范围。此外,每款ECA探头型号都经过精心设计,可在沿探头长度方向上的目标缺陷范围内保持很高的检出率。用户在使用OmniScan MX ECA探伤仪时,可以非常快的速度手动移动ECA探头进行检测,并借助彩色图像和归档功能,完成性能强大、效率很高的检测。

单线圈:光栅扫查 |

阵列探头:单行扫查 |

透过薄涂层进行检测

涡流检测(ECT)技术基于以下磁耦合工作原理:接近被测工件(铁磁性或非铁磁性的导电材料)的探头传感器(线圈)在被测工件中产生涡流,并在仪器的阻抗图中显示信号。使用涡流技术时,只要探头到金属的距离保持在合理的近距离范围内,一般为0.5毫米到2.0毫米,就可以透过薄涂层(如:漆层)探测到材料中的缺陷。

涡流阵列(ECA)和涡流检测(ECT)技术基于相同的基本原理(和物理学理论),因此也可以透过漆层进行检测,而且ECA技术还具有以下优势:覆盖范围大、扫查速度快、检出概率高,及可进行彩色成像。

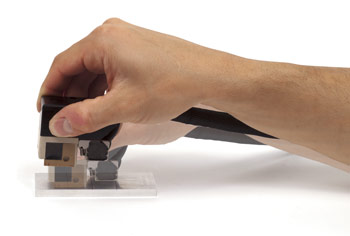

| 涡流检测使用的探头为铜线绕制而成的线圈。线圈形状可以变化,以更好地适用于特定的应用。

|

技术规格

|

OmniScan MX > 总体尺寸 (宽 × 高 × 厚) | 321 mm × 209 mm × 125 mm |

|---|---|

| OmniScan MX > 重量 | 4.6公斤,含模块和一个电池 |

| OmniScan MX > 显示 | 8.4英寸TFT液晶显示,800像素 × 600像素,1千6百万种颜色 |

| OmniScan MX > 电源供应 | 智能锂离子电池(最多两节),直流电输入电压为15 V到18 V(最小50 W) |

| OmniScan MX > 电池供电时间 | 使用两节电池,至少可使仪器工作6小时;正常操作条件下,每节电池至少可使仪器工作3小时。 |

| OmniScan MX > 数据存储 | CompactFlash(闪存)卡、大多数标准的USB存储装置,或者通过快速以太网、内置32-MB DiskOnChip(芯片磁盘)。 |

| OmniScan MX > I/O端口 | 3个USB端口、1个视频输出端口(SVGA)、以太网端口(10/100 Mbps)、双轴编码器接口、4个数字输入端口(TTL)。 |

| OmniScan MX > 工作温度范围 | 0 °C ~ 40 °C; 使用32:128 PA模块时,0 °C ~ 35 ºC |

| OmniScan MX > 存储温度范围 | –20 °C ~ 70 °C,相对湿度为0 % ~ 95 %,无冷凝。无进气孔;防溅设计。 |

| MX模块兼容性 > OMNI-M-ECT4 | 支持常规涡流和粘接检测C扫描(不含适配器) |

| MX模块兼容性 > OMNI-M-ECA4-32 | 支持涡流阵列、常规涡流和粘接检测C扫描(不含适配器) |

| ECT/BT和ECA模块 > 接口 | BNC绝对探头(ECT)接口、4通道通用Fischer 19针(ECT和BT)接口,以及用于连接ECA探头的OmniScan接口 |

| ECT/BT和ECA模块 > 通道数量 | 1到4个(ECT);32个(ECA),通过外置多路转换器可以扩展到64个;1个(BT),带适配器 |

| ECT/BT和ECA模块 > 探头兼容性 |

绝对、差分、桥式、反射式(驱动器-拾波器)与ECT和ECA探头兼容。

通过使用适配器,可支持所选的BondMaster一发一收探头(还需使用扫查器) |

| ECT/BT和ECA模块 > 探头识别 | 自动探头识别,并为ECA和BT探头进行设置 |

| ECT/BT和ECA模块 > 频率 | 大多数ECA和ECT设置有2个一般频率,对于自定义ECT应用或粘接检测C扫描,可多达8个频率。 |

| ECT/BT和ECA模块 > 操作频率 | 20 Hz ~ 6 MHz |

| ECT/BT和ECA模块 > 最大电压 | 12 Vp-p,10 Ω |

| ECT/BT和ECA模块 > 增益 | ECT和ECA:34 dB ~ 74 dB。BT:28 dB ~ 68 dB。 附加可调的软件增益范围:0 dB ~ 30 dB。 |

| ECT/BT和ECA模块 > 相位旋转 | 0°~ 360°,步距为0.1°。 |

| ECT/BT和ECA模块 > 采集(测量)速率 | 1 Hz ~ 15 kHz,根据配置可变。 |

| ECT/BT和ECA模块 > A/D分辨率 | 16位 |

| ECT/BT和ECA模块 > 滤波 | FIR低通、FIR高通、FIR带通、FIR带阻(截止频率可调)、中值滤波器(在2点 ~ 200点之间变化)、平均滤波器(在2点~200点之间变化) |

| ECT/BT和ECA模块 > 通道处理 | 真实的自动混合,灵敏度归一化,以及编码器校准 |

| ECT/BT和ECA模块 > 编码器 | 时基,单行扫查或光栅扫查(双轴) |

| ECT/BT和ECA模块 > 报警 | 3个报警,分别配置为饼形、框形、圆环/圆圈形。报警输出有视觉、TTL和声音类型。 |

| ECT/BT和ECA模块 > 模拟输出 | 有,仅一个通道。 |

粘接检测

涡流阵列软件

提高检测性能、降低复杂程度

MXE 3.0软件

涡流阵列(ECA)检测技术除了增加了晶片之间的电子转换能力外,实际上与涡流检测(ECT)技术并无区别。涡流阵列检测的操作与校准非常容易。OmniScan MXE 3.0 ECA软件经过重新设计,不仅方便了从传统ECT仪器(如:奥林巴斯的Nortec 500)到ECA仪器的过渡,而且可以更便捷的方式提供ECA性能。

|  |

| 单通道ECT | 同时使用32个通道 |

|  |

| Nortec 500的主菜单 | OmniScan MXE 3.0的主菜单 |

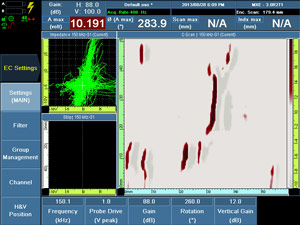

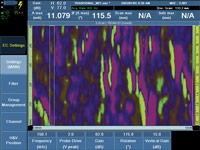

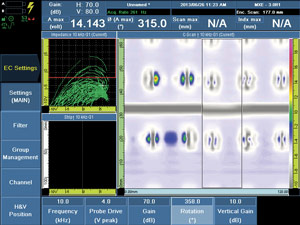

实时阻抗平面图

实时阻抗平面图

ECA校准与传统ECT校准的方式几乎相同。校准过程中继续应用提离、增益和平衡调整原理,因此校准不会比通常情况更复杂、更耗时。

使用ECA探头时,可以实时生成提离信号,这点与使用传统ECT探头一样。

可以使用OmniScan的飞梭旋钮,实时调整相位角度。还可以同样的方式调整增益、垂直增益、平衡点(H/V)位置。

替代传统NDT(无损检测)方法

去除漆层已经过时

涡流阵列具有透过导电材料上的薄涂层进行检测的独特性能。与渗透、磁粉或磁光成像(MOI)等现有检测方式相比,这个性能表现出巨大的优势,因为完全省去了检测前去除漆层或镀层,检测后再重新涂上漆层或镀层的步骤。随着时间的推移,这种检测方式可以为用户节省大量的成本,而且最重要的是检测过程中还不使用化学制剂。

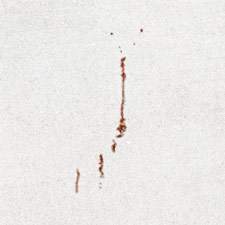

|

|

使用渗透法检测工件(红色渗透剂可见) | 使用标准ECA探头检测得到的扫描视图,带有与渗透检测相同的红颜料图像(专利权受到保护)。灵敏度可调整,以显示更多或更少的缺陷。 |

主要优势:

- 无需去除漆层。

- 成像和归档。

- 一步检测,高速扫查,结果即时。

- 节省了大量的时间(一般可节省10倍或更多的时间)。

- 大大缩短了周转时间。

- 具有缺陷深度评估能力。

- 灵敏度可调,可进行后处理分析。

- 环保方法(不使用化学制剂)。

各种熟悉的调色板选择,提供更多的可能性

MXE 3.0 ECA软件提供一系列受专利保护的、借助彩色调色板表现数据的图像形式,这种图像沿用了传统NDT方式表现数据的外观,而且便于直观地显示ECA信号。

|

|

|

渗透检测(荧光) | 磁粉检测(红色粉末) | 磁粉检测(荧光) |

分析、报告和归档

检测完成后,确认或重新检测

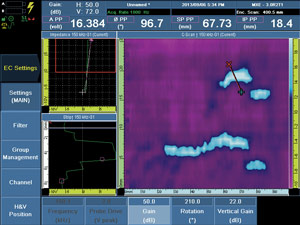

即使在现场检测完成之后,OmniScan MX ECA仍然可以继续发挥其数据存储、分析和制作报告的价值。使用OmniScan MX ECA,用户可以查看单个缺陷指示,并根据需要进行修正。MXE 3.0 ECA软件采用了全新设计、直观的数据光标,可以直接从仪器进行操作(在检测现场),也可以通过USB端口连接鼠标进行操作(在办公室)。

|

|

MXE 3.0软件的选择光标非常直观,可以快速选择任何缺陷指示。 | 可以轻松地对记录的数据进行修正。上面的示例表明对增益(对比度)进行的调整。 |

即刻报告,轻松归档

即刻报告,轻松归档

OmniScan MX内置有一键式报告制作功能。高级用户还可以配置和自行定义报告。不过,厂家默认的报告格式已经包含了屏幕截图和精心选择、预先导入的数据栏区,目的是避免用户自行定制报告的麻烦。

检测数据文件的归档也非常容易;无论在采集还是分析过程中,只需按一下键,即可将数据存储在仪器的存储卡中。

借助鼠标输入,用户可以快速有效地进行数据分析。借助CompactFlash卡的读卡器,用户可以将文件归档到PC机中。

编码扫查,使得数据判读更方便

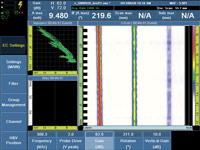

优化后的校准过程只有3个步骤

OmniScan MX ECA不仅可在常规ECT阻抗平面视图中显示ECA信号,还可提供多种其他视图和布局,用户可以从中感受到编码ECA技术真正强大的性能。这些显示可作为校准流程的一部分,可使涡流检测过程清晰可见,甚至可基于用户定义的合格标准做出通过或不通过的判断。

得益于其直观的界面设计,OmniScan MX ECA可以快速方便的配置和操作。配置过程只有简单的3个步骤。

1.使用实时阻抗平面图,实时调整常用的ECT控制。 | 2.激活编码器和C扫描视图。 | 3.微调设置,并为检测做好准备。 |

|

|

|

在全屏C扫描显示中使用增益调节对比度。 |

持续编码器模式

持续编码器模式

时基检测的优势表现在无需对仪器进行过多的干预,就可以提供几乎无限的扫查性能,而编码扫查(C扫描图像)的优点在于可以生成表明缺陷的位置、形状和维度的颇具价值的彩色编码图像和信息。

MXE 3.0 ECA软件推出了一种新的持续编码器模式,可生成编码器经过校正的图像,同时还保留了时基检测的用户友好性。使用这种模式,可以获得很高的检测效率,而且用户可以自由决定是否记录缺陷指示。

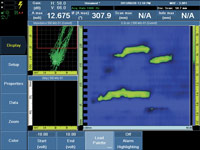

强大的彩色成像功能

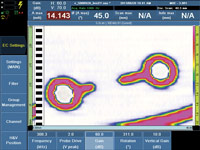

使用彩色编码C扫描评估缺陷的深度

在大多数表面或近表面的应用中,使用涡流阵列技术与使用常规涡流技术一样,缺陷的严重程度与返回的涡流信号波幅密切相关。使用基于波幅的彩色编码,并将每个通道的返回信号绘制成带有编码位置信息的图像,就会使得到的C扫描显示非常清晰直观。这些扫描图像可保存到可插拔CF卡中,也可在OmniScan MX仪器中被制作成报告。

|

|

|

校准涡流阵列(ECA)的灵敏度和对比度时,必须要使用带有深度已知的缺陷的参考标准试块。 | 校准后的ECA扫描图像使用不同的颜色表现每个缺陷深度的范围。 | 图中显示实际飞机蒙皮的腐蚀缺陷指示。不同颜色表明缺陷的不同深度。 |

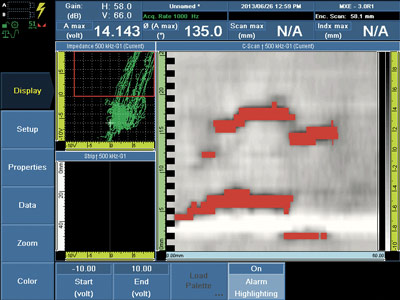

基于阈限值为缺陷做出合格或次品的判定

使用OmniScan MX ECA时,用户可以基于C扫描彩色视图,对缺陷指示做出合格或次品的判定。MXE 3.0 ECA软件包含多种已经厂家测试的彩色调色板,可以优化ECA应用中的信号显示。

此外,C扫描报警功能简化了判废信号的闸门设置情况,因为在阻抗平面图信号进入报警区域时,它可使C扫描颜色即刻得到改变。

|

|

| |

MXE 3.0 ECA软件预先装载了多种适用于不同应用的彩色调色板 | 每当信号处于判废区域时,报警功能就会使C扫描改变颜色。 |

涡流软件

ECT模式下的OmniScan MX仪器,一款性能强大的探伤仪

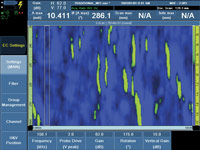

综合使用ECA和ECT技术

某些检测程序可能特别要求使用ECT技术,但是ECA技术却有助于减少检测时间,轻松找到缺陷区域。用户在使用OmniScan MX ECA时,无需在检测开始只使用一种技术。在检测过程中,用户可以随时按住菜单键,即刻在ECA和ECT模式之间进行转换。仪器可以同时与两个探头保持连接状态,而且它们的配置设置可以持续处于激活状态。

同时连接ECA和ECT探头是一种优化的工作方式,因为用户无需停下操作,重新对硬件设置进行配置。

|

按住菜单键…… |

|

与ECT模式或Nortec 500的界面一样,ECA界面(蓝色)使用起来也非常方便。 | ECT界面(绿色)包含多种有助于程序兼容的功能,如:可调节的平衡位置。 |

高质量的信号,已存在的探头

在ECT模式下的OmniScan MX仪器包含高质量信号数字转换器和全数字信号处理链,可以减少信号丢失和失真情况。这个优点加上其明亮宽大的显示屏,使得ECT模式下的OmniSan MX仪器在每次检测时都能呈现高质量的信号,从而跻身于世界范围内优质ECT探伤仪的行列之中。

ECT模式下的OmniScan MX仪器,借助新型线缆和适配器,还可以使用大多数已存在的Nortec ECT探头。