Background

A gear transmission system transmits torque by the meshing of three-dimensionally (3D) shaped gears. Creation of a reliable, highly efficient transmission system with minimal errors in the individual parts or gears, improves transmission accuracy. Errors in the shapes of meshing gears may have negative effects on the quality of transmission. Specifically, errors exceeding tolerance limits in the surface shape of the gears as a result of processing defects may cause subtle wobbling noise during gear rotation. Even if the gear transmission system is able to transmit the required torque, such wobble noise may result in a decrease in the performance and reduce the useful life of the product as a whole.

Olympus solution

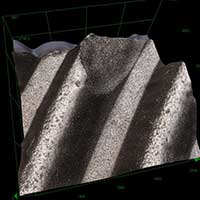

The Olympus DSX digital microscope captures 3D-images that enable any user to easily identify dents and bumps on the surface of the parts. The software package that comes standard with the DSX also provides a variety of measuring tools. All of these features make it the most appropriate device for recording chipped gears and other defective products.

Features of the product

- High-definition, high-resolution image inspection

- Guidance features that allow all users to obtain high-quality results

- 3D image-capture technology

- EFI feature designed to maintain focus across the entire visual field

- Software package contains a wide range of measuring features

- Diverse image-processing techniques

Image

Objective Lens 3.6x , Zoom 1x