Carbon-in-leach (CIL) and carbon-in-pulp (CIP) circuits are gold cyanidation processes that extract gold (Au) from ore by converting the gold to a water-soluble complex. Activated carbon is then used as part of the recovery process by adsorbing the gold from the pulp or solutions derived from the cyanidation. The carbon is then stripped of the gold before being passed through an electrowinning circuit and smelted to produce gold bars. Monitoring the content of gold within the activated carbon is essential to ensure maximum gold recovery.

Leveraging our expertise in X-ray fluorescence (XRF) and integration, Gekko Systems collaborated with Evident to enable their Carbon Scout device to conduct multi-element analysis of carbon with the initial focus on real-time gold circuit inventory.

The Carbon Scout is a self-contained, ground-level sampling system that enables automation of carbon movement by measuring carbon concentration, as well as multi-elements analysis, pH, dissolved oxygen (DO), and density in slurry samples from CIL and CIP circuits. This helps gold mine operators optimize process plant efficiency and reduce soluble gold losses by determining the distribution of the activated carbon in the pulp for each tank (to an accuracy of ±0.5 grams of carbon per liter of pulp). The Carbon Scout improves the accuracy, regularity, and consistency of carbon density measurements in CIL/CIP circuits.

Combining Automated Carbon Management with Portable XRF

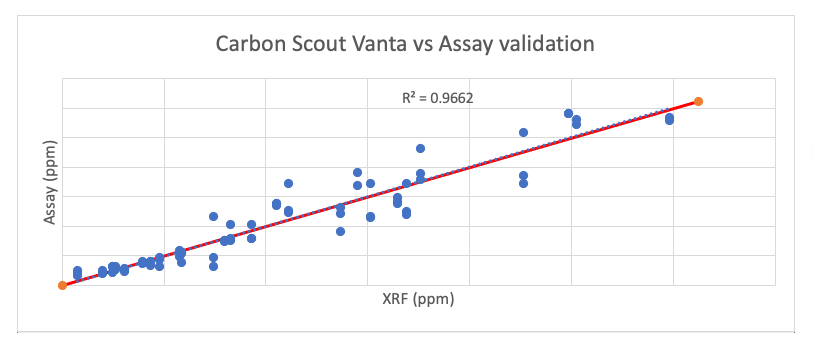

The Carbon Scout can now incorporate the Vanta™ M series handheld XRF analyzer. The Vanta series is a family of leading-edge portable XRF (pXRF) devices commonly used in the mining industry. Known for its reliability and repeatability even in harsh conditions, the Vanta pXRF analyzer provides accurate chemistry for more than 30 elements in solids and liquids samples—from trace level to percent level—across the entire mineral cycle. The graph below shows the data from the Carbon Scout integrated with the Vanta pXRF analyzer vs. assay lab results.

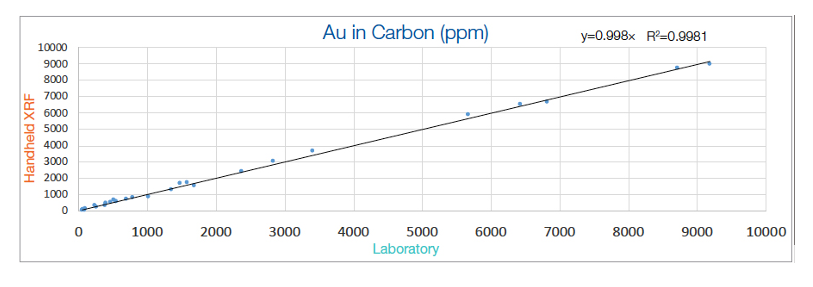

The following graphs compare the Vanta pXRF data with laboratory results for gold (Au) in activated carbon from various mine sites and certified reference materials. The results demonstrate excellent correlation and accuracy between lab and pXRF results. The results also demonstrate the Vanta analyzer's ability to monitor trends in Au adsorption within carbon to support mineral processing decisions and laboratory operations.

Real-Time Monitoring of Gold Loading on Carbon

The speed, accuracy, and precision of the Vanta M series analyzer enables the Carbon Scout to provide real-time monitoring of gold loading on carbon in every tank within the mine site. Site managers can use the live data to confirm that the maximum gold load required in each tank is not exceeded and that carbon is moved and stripped as needed. Further, the data gives a clear view of production achievements and whether targets can be met before undertaking the end-of-month gold-in-circuit inventory.

With data to confirm the day-to-day gold production calculations, the production team can be more confident in their decisions regarding ore blends, throughputs, and unplanned shutdowns.

All this valuable data can be seamlessly streamlined in the gold mine process control systems due to the integrated hardware and software of the Carbon Scout and the Vanta M series analyzer. This custom integration was made possible thanks to our automated inspection solutions team.

To learn more about XRF and automated carbon management in mining, check out the Carbon Scout page and our resources on portable XRF in mining and geochemistry.

Related Content

Portable XRF Analyzers for Measuring Gold in Activated Carbon

Can Vanta Portable XRF Measure Gold (Au) to Less than 20 Parts per Billion?

Video: Felix Gold Uses Handheld XRF for Exploration and Discovery