Background

Hologram printing is a unique method for printing with red, blue, and green on the printing surface. The image turns iridescent when viewed from a certain angle. Due to its unique capability to produce images that can’t easily be reproduced by ordinary copies or photos, this method is used for a variety of purposes, including printing paper money and credit cards to prevent counterfeiting. However, since counterfeiting technology continues to develop, there has been increased demand to further develop micro-printing technology.

Olympus solution

The DSX enables users to easily inspect and record the quality of hologram printing, while the DSX enables users to observe the shape of parts to diagnose defects from multiple angles, in much greater detail.

Features of the product

- High-definition, high-resolution image inspection

- Guidance features that allow all users to obtain high-quality results

- EFI feature designed to maintain focus across the entire visual field

- 3D image-capturing technology

- Software packages that contain a wide range of measuring features

- Diverse image-processing techniques

- Differential interference contrast

Image

|  |

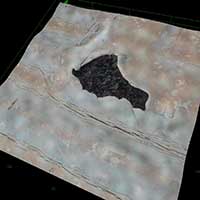

| Wide Area Image of the Print Surface | Print Failure Point |

| (Objective Lens 3.6x , Zoom 1x) | (Objective Lens 50x , Zoom 1x) |