在线研讨会

Webinar: Easy Ultrasonic Phased Array Inspection

This webinar will provide an easy, step-by-step overview of the points to consider when carrying out ultrasonic (UT) inspections of austenitic or dissimilar material welds. It also shows how Olympus’ comprehensive range of flaw detection products — such as the FOCUS PX™ acquisition instrument, the OmniScan® flaw detector, and phased array probes and wedges — can be used to facilitate the inspection process. |

Easy Ultrasonic Phased Array Inspection

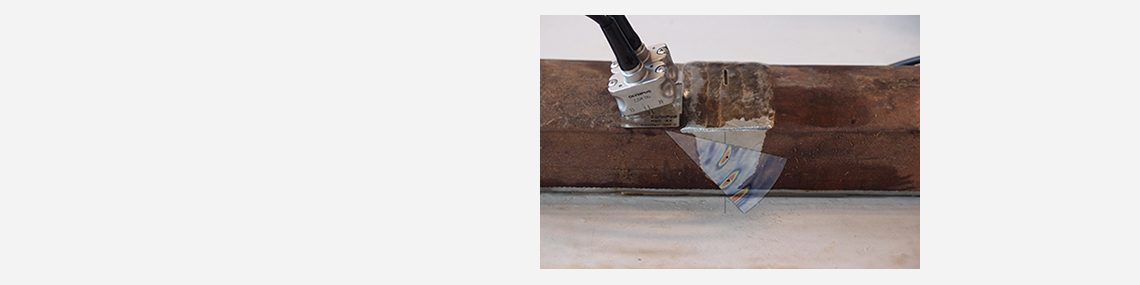

Many industries increasingly use austenitic welds and welds containing dissimilar materials. These welds can be used to create components with improved or tailor-engineered properties. For example, a part may need high temperature resistance in one area and good corrosion resistance in another. Other structures may need a combination of toughness or wear resistance in one location and high strength in another location. The inspection of these types of welds with ultrasonic phased array technology is associated with challenges relating to the changes in density and acoustic properties of the materials (anisotropy). This webinar will provide an easy, step-by-step overview of the points to consider when carrying out ultrasonic (UT) inspections of austenitic or dissimilar material welds. It also shows how Olympus’ comprehensive range of flaw detection products — such as the FOCUS PX™ acquisition instrument, the OmniScan® flaw detector, and phased array probes and wedges — can be used to facilitate the inspection process.

Presenter:Thierry Couturier - Senior Product and Applications Specialist – UT and PAThierry is an electronics engineer and has more than 27 years of experience in phased array (PA), conventional ultrasonic testing (UT), and time-of-flight diffraction (TOFD). He has designed numerous ultrasonic inspection systems and provided technical support for PA applications, including weld inspection on pipelines, pressure vessels, and infrastructure; composite inspection in aerospace; and corrosion inspection. |  |

Related Products

OmniScan MX2

The OmniScan MX2 now features a new phased array module (PA2) with a UT channel, and a new two-channel conventional ultrasound module (UT2) that can be used for TOFD (Time-of-Flight Diffraction), as well as new software programs that expand the capabilities of the successful OmniScan MX2 platform.