Remote visual inspection (RVI) is a key element of plant maintenance to help prevent leaks or other accidents that can result in significant losses. Plant shutdowns are expensive, which means that fast, efficient inspections that do not compromise on reliability are highly beneficial for plant profitability. Although other inspection technologies exist, RVI is the only method that provides true-to-life images for confident decision making. Plants are challenging due to the wide range of equipment that needs to be inspected (see table on page 2). Each piece of plant equipment comes with its own specific inspection challenges, which can relate to the shape of the component (small holes, tight spaces) or to its condition (damage, fouling). |  |

Typical Inspection Tasks and Challenges in Plant Maintenance

| Equipment | Part to be inspected | Defects | Challenges in RVI inspection |

| Pipes | Connections, elbow joints | Clogging, cracks pinholes, poor welding, linings | Confined spaces, dark conditions, image traceability, high temperatures (sometimes) |

| Boilers | Tube interior, headers | Clogging, cracks, wastage, poor welding, linings | Dark conditions, camera instability, reflective surfaces, high temperatures |

| Heat exchangers | Tube interior | Clogging, cracks, wastage, linings | Confined spaces, dark conditions, image traceability, high temperatures |

| Turbines | Turbine blades, combustion chambers | Cracks, wastage | Dark conditions, camera instability, reflective surfaces, high temperatures |

| Vessels / reactors | Internal pipes, vessel bottoms | Clogging, cracks wastage, poor welding | Confined spaces, dark conditions, camera instability, high temperatures, high levels of radiation |

| Valves | Connections | Clogging, pinholes | Dark conditions, reflective surfaces |

The latest generation of videoscopes is equipped with innovative features that are specifically designed to address these complex inspection challenges. These videoscopes provide high return on investment due to faster inspections and better informed decision making.

Overcoming Accessibility and Manoeuvrability Challenges

To carry out a comprehensive inspection of large structures, such as pipes, reactors, or heat exchangers, it is important to obtain images of even the most hard-to-access locations and surfaces. This means that camera accessibility is a key challenge in RVI inspections. As a result, there are highly specific demands on both the dimensions of the scope and the level of control over its movement.

The intuitive articulation of the Olympus IPLEX NX® videoscope (Figure 1) enables easy maneuvering in even the most challenging environments, such as the long, narrow pipes found within heat exchangers. Inspectors can move the scope tip with more control and precision when navigating around corners, narrow spaces, and through difficult or tight openings. TrueFeel power-assisted mechanical articulation uses a joystick to control the tip, which provides advanced hand–eye coordination for working in confined spaces and saves time on inspections (Figure 2).

Figure 1—Plant maintenance inspections become easier and faster when using the latest generation of RVI tools, such as the Olympus IPLEX NX videoscope. |  Figure 2—Joystick-based articulation provides an intuitive way to maneuver in confined spaces. |

The recommended scope for the IPLEX NX videoscope has a diameter of 6 mm and a length of 7.5 m (24.6 ft), which enables inspection of tubes up to 15 m (49 ft) when accessible from both ends. The 6 mm scope with a distal end rigid section—that is up to 1.3 times shorter than conventional videoscopes—makes it possible to inspect narrow tubes while still benefiting from high light intensity. For the smallest tubes and openings, a 4 mm tip can be used.

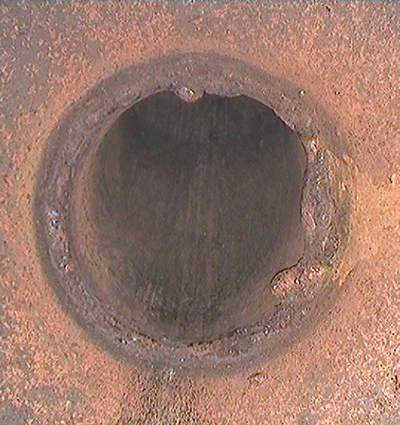

Improved Image Quality for Better Probability of DetectionIn all types of plant equipment, poor image quality can lead to reduced probability of detection (PoD) of faults such as cracks, blockages, corrosion, or crystallization. These can be critical defects which, if missed during an inspection, can cause leaks or component failure leading to significant downtime. Light output, camera quality, and image processing all play a role in determining the level of detail in an image (Figure 3). Olympus’ extensive optics expertise, combined with bright laser diode illumination and a large CCD screen, results in high-quality images for a high PoD. In addition, the advanced imaging bundle included with the IPLEX NX videoscope provides active noise reduction as well as sharpness and saturation control, helping to ensure that no defect is missed. |  Figure 3—PoD improves with bright, even illumination of features and surfaces. |

Ensuring Image Identification and TraceabilityInspecting a large, complex structure—such as a heat exchanger—often requires accessing a large number of narrow pipes to look for evidence of fouling. This involves taking many images of similar structures and features. To use these images in a detailed, comprehensive report, full image identification and traceability (knowing which image was taken where) is essential. However, when this is done manually, it can be a highly time-consuming and error-prone process—especially when adding information image after the inspection is complete. Olympus provides intuitive software combined with an easyto- use touchscreen interface to help inspectors ensure full traceability of each image in their inspections. Using the InHelpTM inspection assist tool, adding a precise location to each image is simple. InHelp software also enables annotation of images during the inspection, which makes the creation of an inspection report both faster and more reliable. |  Figure 4—With a monitor extension cable, the scope can be operated while the monitor is placed in an easy-to-view area. |

Combating Camera Instability in Large Spaces

When inspecting the interior of, for example, expansion vessels or large-diameter pipes, it can be hard to acquire a stable image due to movement of the camera. Taking clear images requires the scope tip to remain stable and centralized. The use of Olympus Flex-and-Stay guide tubes help to provide the necessary stability, resulting in even illumination and improved image quality.

Inspections in Hard-to-Access Locations

The complex layout of a plant often means that certain application areas need to be accessed from a difficult location. An inspector may have to pass through a number of other valves, pipes, and expansion tanks—to access a pressure vessel or heat exchanger—all while working within confined spaces. With a conventional videoscope, it is necessary to place the monitor as close as possible to the component to be inspected. In inaccessible locations, there might be no space to place the monitor, which means that the inspector needs to consider exactly where to place various items of equipment. This makes it challenging to operate the scope and to see the monitor at the same time.

The monitor extension cable of the IPLEX NX videoscope enables easier operation when space is limited and makes it possible to place the monitor away from the videoscope in an easy-to-view area (Figure 4). The videoscope can now be used in a more versatile way, enabling hands-free operation, even in hard-to-access locations. In addition, the use of the optional remote control gives an inspector total control over their inspection from different locations within the plant.

Summary

Plant inspection using RVI technology requires a versatile videoscope that can produce clear images regardless of the equipment to be inspected. Olympus’ IPLEX NX videoscope combines world-renowned imaging capabilities with a host of innovative features that solve real-world problems. It helps inspectors to save time on inspections and to produce reliable, comprehensive reports—thereby providing a fast way to ensure plant safety and profitability while simultaneously limiting downtime.