Heat exchanger tubes are everywhere; from the petrochemical industry to air conditioners, exchangers are important in nearly every type of facility. The tubes are often under high pressure, exposed to dramatic temperature changes, and sometimes have corrosive materials flowing through or around them. These conditions can lead to tube erosion and cracks. If these problems aren’t addressed, the system can fail, leading to significant potential downtime.

The importance of heat exchangers necessitates a regime of regular inspection. However, these inspections can be challenging. The inspection can be time-consuming with some exchangers having thousands of tubes. In addition, exchangers are made out of a variety of materials, making inspection using a single technology difficult. Lastly, the NDT equipment used for the inspection can be expensive and tough for a single person to use. Having to send two people on an inspection job further adds to the overall cost.

Our heat exchanger tubing kit for the NORTEC® 600D flaw detector is helping to make tube testing faster and more efficient. With the kit, you can inspect any combination of ferrous, non-ferrous, finned, or un-finned tubing. A major advantage of the kit is that it supports multiple technologies—eddy current, remote field, and near field—enabling this solution to be used to inspect just about any exchanger tube that’s out there.

What can you inspect?The kit comes with four adaptors. The eddy current adaptor is used to inspect non-ferromagnetic material and is compatible with A/C probes, enabling the detection of circumferential defects. The remote field adaptor is used to inspect un-finned carbon steel, while the near field adaptors are used to inspect finned carbon steel tubes. |  The kit’s four adaptors enable you to use a variety of probe types |

What probes can you use?Almost every Olympus probe with a cable length less than 82 feet (25 meters) can be used with the kit. Use this list as a guide to help you pick the right probe for the right tube. |  A variety of materials can be inspected with the kit |

- Non-ferromagnetic, un-finned tubes

- TEA/TEB — Bobbin probe (attached/detachable)

- TEC/TED — AC probe (attached/detachable)

- TEE/TEF — Titanium casing probe (attached/detachable)

- TEG — Flexible bullet probe

- TEK/TEL — High-resolution probe (attached/detached)

- Non-ferromagnetic, finned tubes

- TEC/TED — AC probe (attached/detachable)

- Non-ferromagnetic U-bend tubes

- TEG — Flexible bullet (attached)

- Semi-ferromagnetic, un-finned tubes

- TEO — Carter magnetic probe

- TRS — Single exciter remote field probe with high frequency

- TRX — Dual exciter remote field probe with high frequency

- Ferromagnetic, un-finned tubes

- TRS — Single exciter remote field probe

- TRX — Dual exciter remote field probe

- Ferromagnetic, finned tubes

- TRD — Near field probe

- Boiler tubes

- TRC — Flexible boiler probe

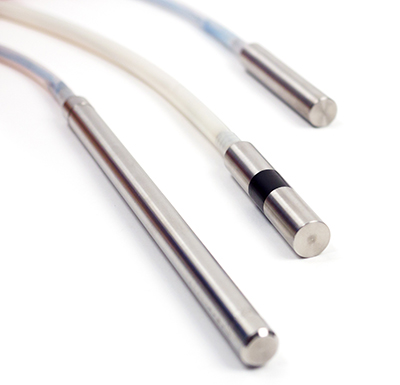

If you already own probes, you’re ready to start inspecting—the kit is compatible with the probes you already own. Otherwise, browse our catalog to get the right probe for the job. |  A TRX remote field probe (front), a TEA eddy current probe (middle), and a TEC A/C probe (back) |

How does the kit make my inspections easier?For added efficiency, the kit comes with heavy duty pedals that enable a single inspector to clear the screen (erase) or perform a null on the flaw detector while they work. Using the pedals helps improve productivity and shorten the inspection time. |  Null and erase without disturbing your work |

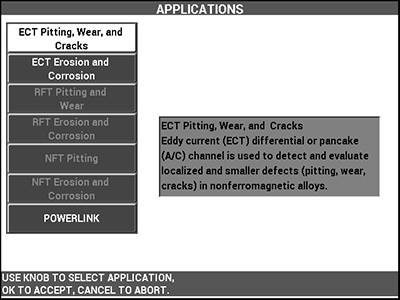

The kit uses the NORTEC 600D flaw detector, an instrument that’s lightweight (3.7 pounds, 1.7 kilograms) and simple to use. It has a battery that lasts more than a full shift on a single charge (10 hours) and a convenient stand that makes it easy to position the instrument in your work environment—rest it on a surface or hang it from an exchanger or beam to keep it at eye level. A suite of software features also helps streamline tube inspection. Application presets enable you to spend more time fine-tuning the instrument rather than configuring it. |  Application presets |

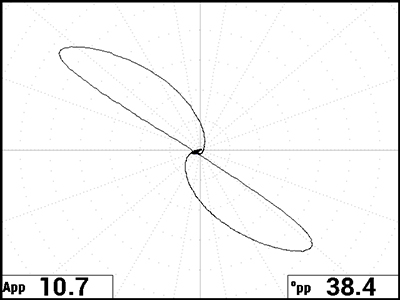

The NORTEC 600D flaw detector delivers crisp signals and multiple display options to help increase the probability of detection. |  A good signal quality helps make inspections easier |

The freeze mode is great for tweaking the signal. It enables you to adjust the gain and rotation of the signal right on the screen. There’s also a full-screen mode so that you can focus on what’s important. |  See your signal in full-screen mode |

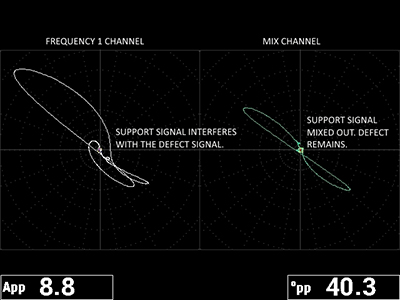

If you’re working around a support, it can interfere with your signal. The mix channel feature mixes out the signal from the support to better identify defects located in close proximity to it. |

Work around supports |

If you need more information about tube inspection, don’t hesitate to contact us.

Get In Touch