Streamlined Thickness Data Collection and Processing

All 72DL PLUS™ models have built-in datalogging with up to 2 GB of data storage, along with convenient onboard file management features.

- On-screen alphanumeric keypad for file naming and editing report headers to organize your work

- File Manager menu makes it simple to review and edit application files, review and delete inspection data files, and see the inspection completion percentage; once a file is identified, it can be conveniently recalled

- Connect a foot switch for hands-free activation of the save/send data function

Easy Application Setup for Routine Thickness Measurements

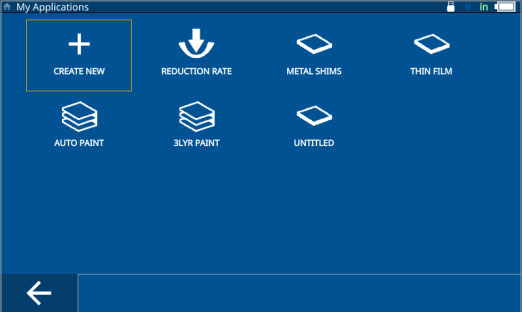

For routine applications on simple or complex parts, store and recall settings in the My Applications menu to simplify the device setup process. This reduces manual selection and setting adjustments before each inspection, enabling efficiency and confidence in the measurement quality.

The My Applications menu makes it easy to create custom applications right from the gauge:

- Predefined configurations for single layer, multilayer, barrier, and reduction rate

- Menu guides you through each process step, from choosing the configuration for an inspection to setting up the transducer, material, alarms and alarm conditions, measurement mode, and the part map

- Applications are easy to recall—just turn on the gauge and the instrument shows the My Applications menu as the startup screen

For added flexibility, the PC Interface Application can also be used to create applications and send the files to different gauges on the production floor or across facilities.

Get to Work Fast with Standardized Inspection Guidance

With the interactive custom template, inspectors can do their job faster and without stress by following standardized inspection guidance on the gauge. Supervisors can have more security that a job is done right by intelligently monitoring the quality and progress of ongoing thickness inspections.

- Save time and resources training inspectors:create custom part maps and setups once and push them to all your instruments; all inspectors follow the same process to consistently evaluate the thickness of parts

- Confidence in your thickness inspections: know you’re capturing data at every required thickness inspection location; see progress with color-coded inspection points for each stage—before measuring, active thickness measurement location (TML), after measuring, and alarms/loss of signal (LOS)

- Easily retake thickness measurements as needed: quickly confirm out-of-spec measurements identified by alarms/LOS readings

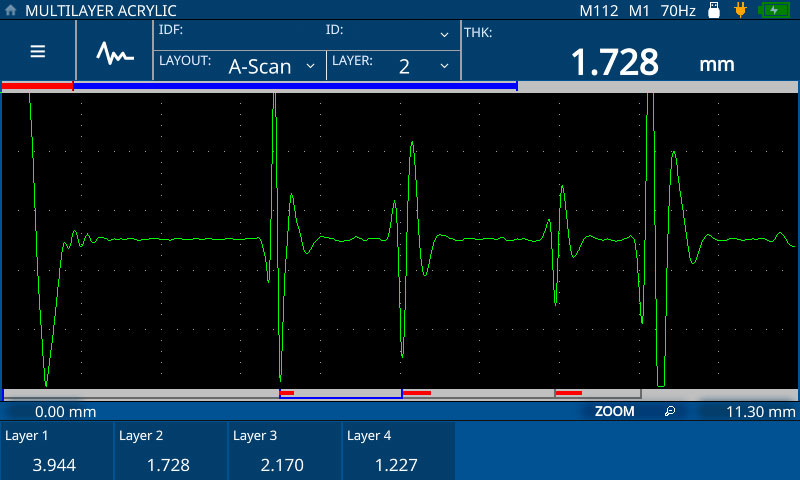

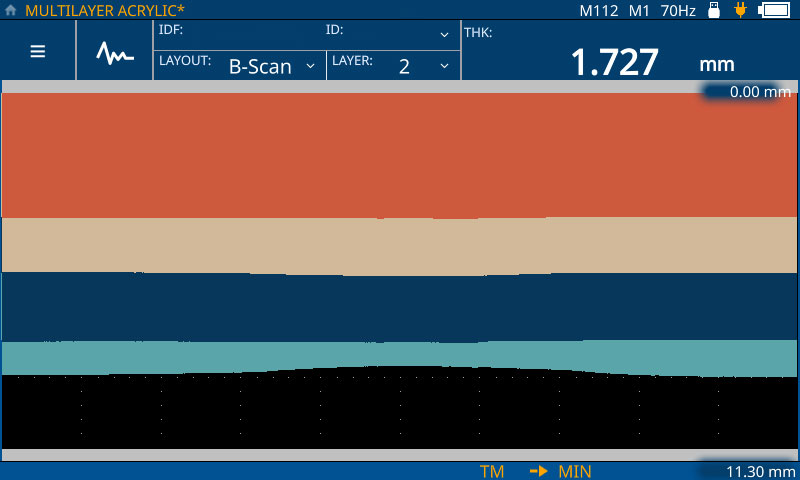

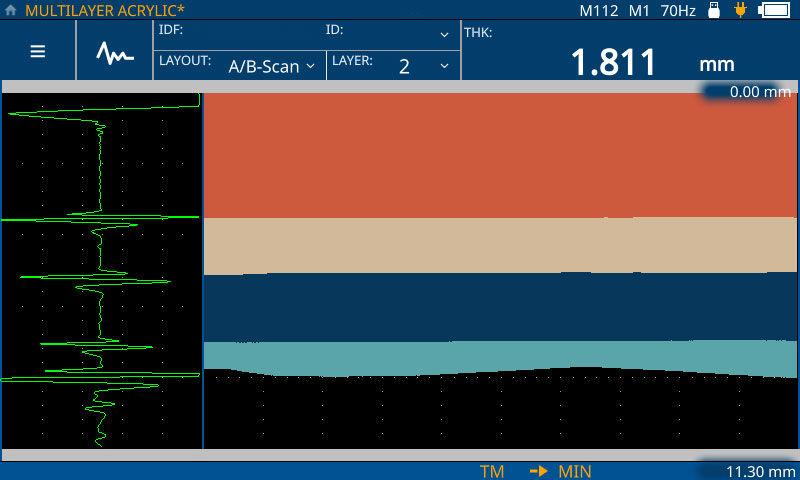

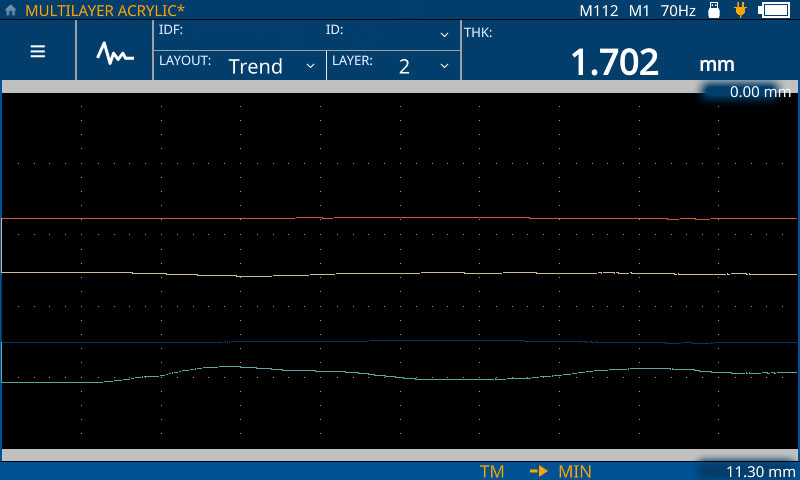

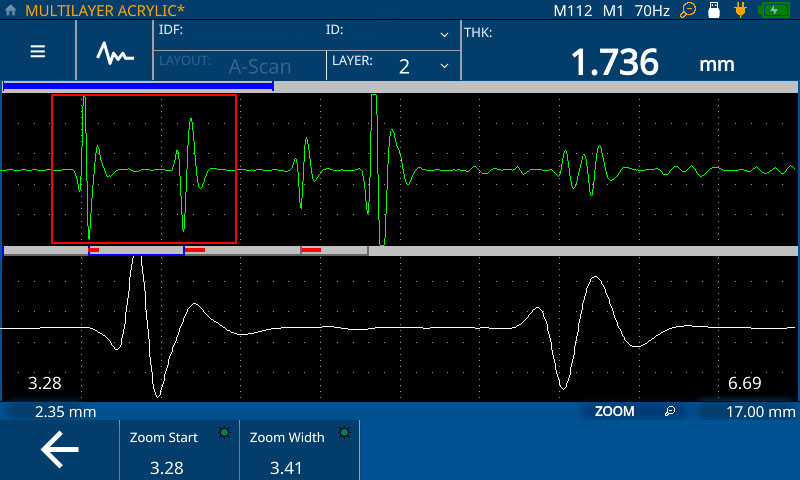

Track and Visualize Thickness Changes with Versatile Measurement Layouts

All 72DL PLUS models include five measurement layouts, so thickness changes on a test material can be accurately tracked and visualized.

A-Scan

B-Scan

A/B-Scan

Trend

Zoom

Improve Product Quality with Inspection Data Management and Analytics

Collect more inspection data to better control product quality. The PC interface application offers data creation, management, sharing, and analysis tools to empower data-driven decisions on the manufacturing production floor. Monitor thickness trends, spot quality issues, and generate reports to help maintain consistent product quality and improve processes.

- Monitor thickness trend changes: analyze data points in statistics, trendline, and histogram views

- Spot quality issues: see the history of a part or measurement locations across multiple parts in the analytics dashboard

- Assess inspection quality: organize data and application files from multiple gauges in a single storage location

- Generate manufacturing inspection reports in a PDF format for individual components or entire production lines using customizable templates

- Fast, simple data recording: supports data transfer using USB and Wi-Fi® to reduce errors and bias in data collection; data can be exported to Excel for further analysis