Background

Tools with electrodeposited diamond grains are designed to grind and machine hard materials such as cement, carbide, ceramic, and quenched ferrous and non-ferrous metals. The electrodeposition process uses electrical current to bond the diamond grains onto a base metal. This results in a rigid tool with excellent cutting performance. As these tools are used, they wear causing the diamond grains to fall off the base metal. At a certain point, wear negatively affects the tool’s accuracy and machining speed. Consequently, manufacturers must regularly inspect the condition of diamond grain coated tools.

The Olympus solutions

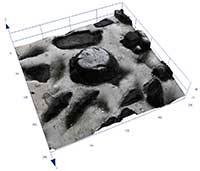

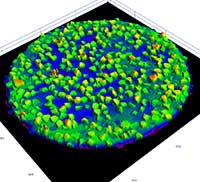

The Olympus LEXT 3D laser measuring microscope enables you to inspect the surface of a diamond electrodeposited tool to assess its condition (Figure 1). The side surfaces of electrodeposited diamond grains have steep angles with respect to the base metal surface. Conventional laser microscopes have difficulty measuring these steep surfaces because they reflect only a small quantity of light. The LEXT, however, has exceptional inclination detection capabilities and can measure surfaces with an angle up to 85°. This capability enables the LEXT to create accurate three-dimensional renderings of microstructures that have steeply-inclined configurations (Figure 2). The LEXT has an imaging function that stitches up to 625 images together while enabling you to exclude unwanted images from the overall picture.

Features of the product

The LEXT has ultra-high-resolution 3D visualization and measurement capabilities combined with high pixel density. It is capable of making accurate and reliable measurements of samples with steep angles. The imaging feature enables you to stitch images together to obtain a complete view of the tool surface being inspected.

Images

|  |

| Figure 1: An electrodeposition tool showing diamond grains embedded in the metal surface | Figure 2: A diamond electrodeposited tool surface |