Application

Liquid crystal displays (LCDs) must exhibit uniform brightness. To achieve this, special-purpose films are laminated together as part of an illumination optical system. The light from a source such as LEDs installed at the edge of a light guide plate is repeatedly reflected as it scatters within the plate, illuminating the plate’s front side. After the light radiating from the plate is made uniform by the diffuser plate and collected by a prism sheet, it is very intense. The intense light then enters into the TFT LCD panel. In order for this process to work effectively, the surface of the diffuser plate must be uniform. Consequently, evaluating the surface profile of the plate is important.

The Olympus solution

With Olympus' LEXT 3D laser scanning microscope, users can observe the surface roughness of the diffuser plate and the dispersion of random irregularities with high resolution and high contrast. The LEXT features dedicated objective lenses with high numerical apertures and an optical system that obtains maximum performance from the 405 nm laser to capture the profile of irregular slopes that were previously difficult to detect, enabling you to easily acquire more reliable three-dimensional data.

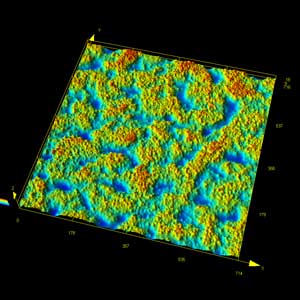

Front surface of a diffuser plate in 3D

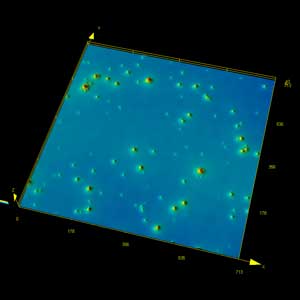

Objective lens 50X, Zoom 1X; 3×3 stitching | Back surface of a diffuser plate in 3D

Objective lens 50X, Zoom 1X; 3×3 stitching |