Application

Machines used to manufacture textiles for clothing are equipped with a large number of guides to wind up or guide the yarn. These guides are important because the yarn makes direct contact with them at high speed. If the surface of the guide is too rough, the yarn can get caught on the guide and break or the yarn’s quality may be affected due to heat caused by friction. It is important to quantitatively evaluate the surface roughness and irregularities (both microscopic and scratches) on

the surface of the guides.

The guides are made out of a durable ceramic. Ceramics have small but rugged irregularities on the surface that are difficult to measure using conventional contact-type roughness measurement instruments or 3D micro measuring machines, such as white light interferometers. Until recently, these micro measuring machines were the only tools available for measuring the surface roughness of these guides, and there were no tools available to measure the roughness of the very small area that makes

contact with the yarn.

The Olympus solution

Olympus' LEXT 3D laser scanning microscope enables non-contact 3D shape measurement with high resolution and high precision. Users can accurately measure surface roughness and the depth (or height) of surface irregularities. The LEXT utilizes the same roughness (two-dimensional) parameters as contact-type microscopes, providing measurement results that are compatible with contact-type microscopes. The LEXT also has three-dimensional roughness parameters that comply with ISO25178, enabling you to obtain more information than line roughness through surface-area evaluation using both 3D images and numerical data.

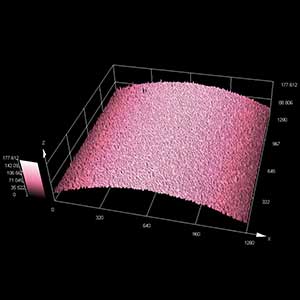

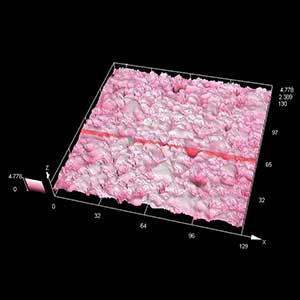

Surface of a bar guide

Objective lens 10X, Zoom 1X |

Objective lens 100X, Zoom 1X |