1. Background

A vehicle’s overall quality is equal to the sum of its parts, and it is imperative for manufacturers to maintain rigid standards of excellence for every component. Manufacturers must also take into account requirements such as emission reduction, fuel efficiency, long-term durability, and regulatory standards. The increasing complexity of auto parts and components also requires manufacturers to place a strong emphasis on material characteristics, fitting tolerances, and technical cleanliness, which all play a strong role in the long-term durability, durability, and life-expectancy of the final product.

2. Application

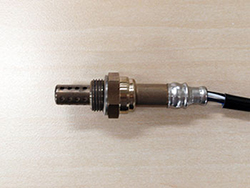

Automotive O2 (oxygen concentration) sensors placed in a vehicle’s exhaust pipe can experience temperatures fluctuations from 700 to 1,000 degrees Celsius. Constant exposure to such high temperatures, coupled with inadequate pressure-bonding/welding, may cause the sensor’s metal housing to crack, break, or results in other defects.

3. The Olympus solution

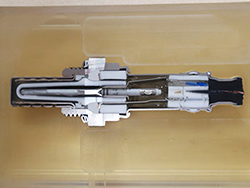

Paired with OLYMPUS Stream software, the Olympus BX53M industrial microscope provides detailed visual observation of the sensor’s metal housing and connections. BX53M microscopes also offer a seamless workflow for standard microscopy and digital imaging users, as well as dispersion-free optical performance, thanks to Olympus’ exclusive wave-front aberration control technology. LED Illumination allows for color-variation-free lighting adjustment, while the observation method may be altered with the simple turn of a dial.

O2 sensor: External view

O2 sensor: Cross-sectional view

Metal Cover Connections