Introduction

Traditionally, measuring and visually inspecting a gun barrel require two separate methods—one qualitative and one quantitative.

Routine inspections typically combine both: a visual inspection to assess the condition of internal surfaces, and physical measurement to detect dimensional wear or deformation.

Why Inspect Gun Barrels?

Gun barrels are subject to extreme pressure, heat, and friction. Regular inspection is critical to ensure safety, performance, and compliance with quality standards.

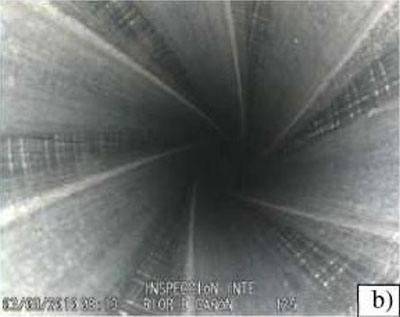

Visual inspection with a high quality Borescope or Videoscope allows identification of any defects such as removal of chromium plating, particularly in the forcing cone, or the leading edge of rifling, erosion, pitting, scoring or in extreme circumstances, rifling that has been stripped from the barrel.

This visual inspection can be carried out to assess the condition of the weapon and determine if it is safe and reliable for use.

Gun Barrel

Objectives

- RVI Gun Barrel inspection - To enable the inspector to accurately and clearly view the internal barrel condition

- 50% increase in detection of Gun Barrel Erosion & Fatigue Life

- Reduced Life Cycle Cost

- Improved Gun Barrel Thermal and Ballistic Performance

Payoffs

- Increased Gun System Availability

- Improved Ballistic Capability

- Precision

Fig. 1: Its just an illustration, of how it could be used. |

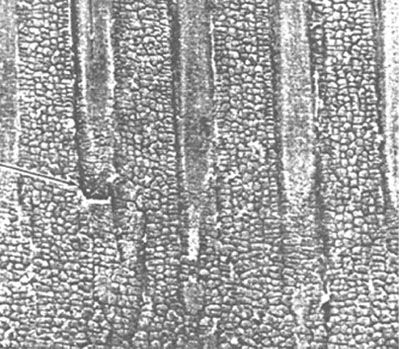

Fig. 2: Internal view of rifling wear captured using the IPLEX GX videoscope. |

Fig. 3: Residue check under White and UV light using the IPLEX G Lite system. |

Barrel Wear and Erosion

- Thermally induced stresses create heat check cracks during firing

- Underlying substrate is thermally altered (HAZ)

- Subsequent chemical attack of steel from combustion gasses undermines chrome

- Chrome “islands” are jeopardized until they break free and leave steel substrate exposed

- Steel substrate is rapidly eroded by high velocity combustion gasses and accelerated chemical attack at high temperatures

The Effects of Barrel Wear and Erosion

Erosion of the gun bore occurs mainly at the origin of rifling-the point in the gun bore near the breech where rifling begins.

In guns using bag or semi-fixed ammunition, the projectile may be rammed further into the gun which has the effect of reducing the density of loading, and hence the muzzle velocity is decreased.

Erosion also causes the tops of the lands of the rifled bore to wear away faster than the bottoms of the grooves, which increases the amount of gas which escapes past the rotating band. This further reduces the pressure behind the projectile and thus decreases muzzle velocity.

Even a slight amount of erosion reduces the muzzle velocity, range and accuracy of a gun.

The gun eventually becomes unserviceable when erosion reduces its effectiveness to a point where the projectiles fired no longer hit the target.

Before a gun becomes inaccurate due to erosion, the barrel must be replaced or relined (in guns equipped with removable barrel liners).

The life of a big gun is less in terms of rounds fired than that of a machine gun.

A record is kept of the number of rounds fired by each gun so that proper information on bore erosion can be supplied for fire control purposes, and to enable the gunnery officer to know when the barrel needs replacing.

Conclusion

Remote Visual Inspection (RVI) using Evident’s borescope solutions offers a fast, reliable, and non-invasive method to inspect gun barrels across defense and manufacturing sectors. By combining precision optics, portability, and advanced lighting, IPLEX GX/GT and G Lite provide the clarity and efficiency needed to detect critical issues early and extend barrel life.

Note: Both systems support image capture and on-site review, allowing seamless documentation and decision-making.