Introduction

Small diameter tube and pipe inspection can be difficult. Challenges include the fact that pipe-to-pipe clearance is typically very small; access to the pipe is limited to only one side; and the wall thickness and diameter are quite small, making typical phased array (PA) probes unusable. Because of the size of the probes and scanners, radiography was typically preferred over phased array and conventional ultrasound methods.

Phased array offers several advantages over radiography when it comes to inspecting small diameter tubes and pipes. Often, a series consecutive inspections are required, so the system that is being used must be able to provide repeatable results one inspection after the other. Small diameter tube and pipe inspection systems also must fast and capable of quickly moving from one inspection area to the next. The Olympus COBRA® scanner was optimized to overcome the traditional limitations of phased array inspection for small diameter tubes and pipes with features including:

- Slim scanner, PA probes, and wedges enable complete coverage of the pipes since only a small pipe-to-pipe clearance is required to perform a 360° scan.

- The scanner adheres to the pipe or tube using a spring mechanism that enables 360° coverage, even when only one side of the pipe or tube is accessible.

Solution

The COBRA scanner phased array solution offers a fast, practical system for small diameter pipe and tube inspection. By using ultrasonic technology, users can avoid the inherent difficulties and disadvantages that accompany radiographic inspection, such as safety concerns, regulatory issues, the technique’s slow speed, and the need to clear people out of the inspection area during testing.

Olympus’ 80° TOFD wedges further enhance the capabilities of the COBRA solution. While keeping the advantages of the COBRA scanner discussed above, the TOFD technique is a cost-effective solution that is very sensitive to volumetric defects in small diameter pipes.

|

|

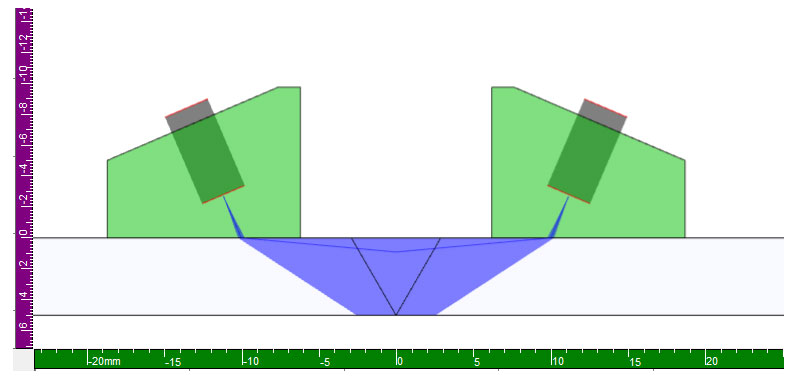

Scan plan of the TOFD inspection of a 5 mm thick pipe using the 80° COBRA wedges and 15 MHz transducers.

|

|

|

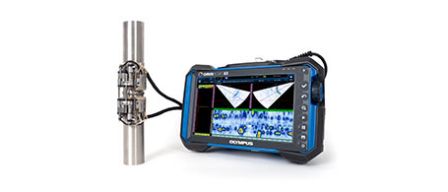

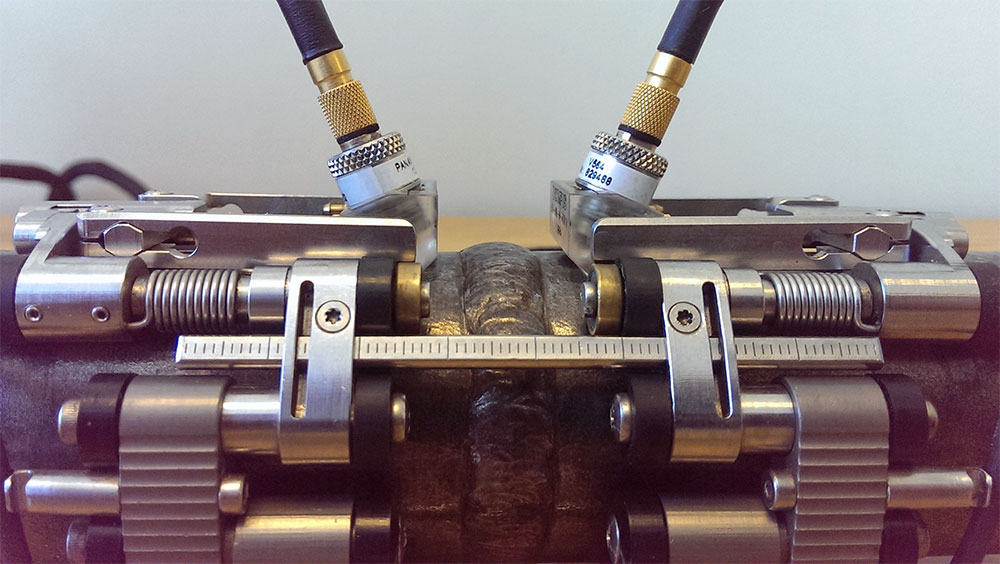

COBRA TOFD wedges and transducers assemble in the scanner and on the part.

|

TOFD is a well-established technique that has a long history of use for general weld inspections. It has proven to be a fast and easily deployable method with an excellent capacity for sizing. One of the inherent strengths of TOFD for detection and sizing purposes is its relative indifference to the orientation of defects because of its primary use of diffracted versus reflected energy.

Ultrasonic transducers are positioned on each side of the weld; one transducer sends the ultrasonic signal into the material and the other receives reflected and diffracted ultrasound from discontinuities and geometric reflectors. TOFD provides a wide area of coverage with a single beam by exploiting ultrasonic beam spread theory inside the wedge and the inspected material. When the ultrasound signal comes in contact with the tip of a flaw, or crack, diffracted energy is cast in all directions. Measuring the time of flight of the diffracted beams enables accurate and reliable flaw detection and sizing, even if the crack is off-oriented to the initial beam direction.

The kit of COBRA TOFD wedges includes one pair of flat wedges plus nine pairs of curved wedges to cover pipes with an OD range of 1.05 in. to 4.5 in. The wedges are designed to fit ST1 probes with 3 mm diameter elements. Note that the use of these wedges will increase the minimum clearance required for the use of the COBRA scanner compared with the phased array option.

|

|

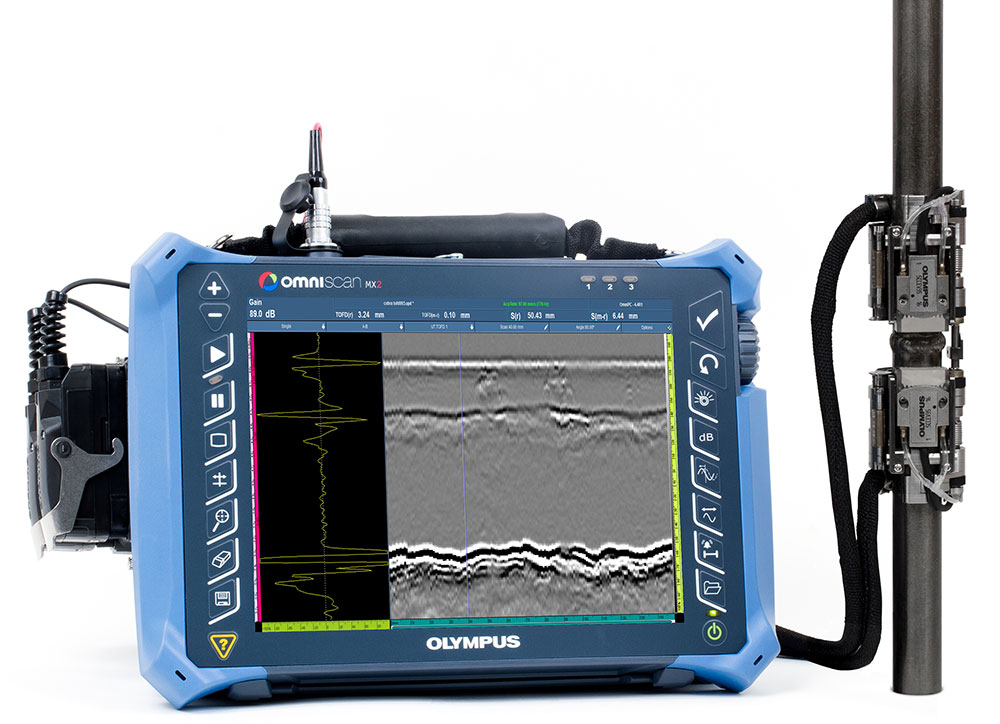

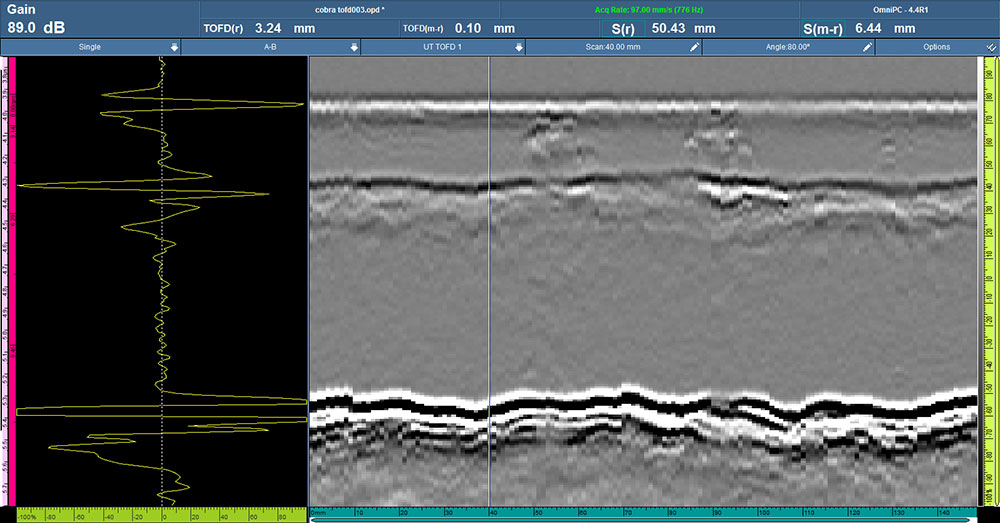

Scan of a weld with the cursor positioned on a clean area; the A-scan shows a good lateral wave and back wall signal with no indications in between.

|

|

|

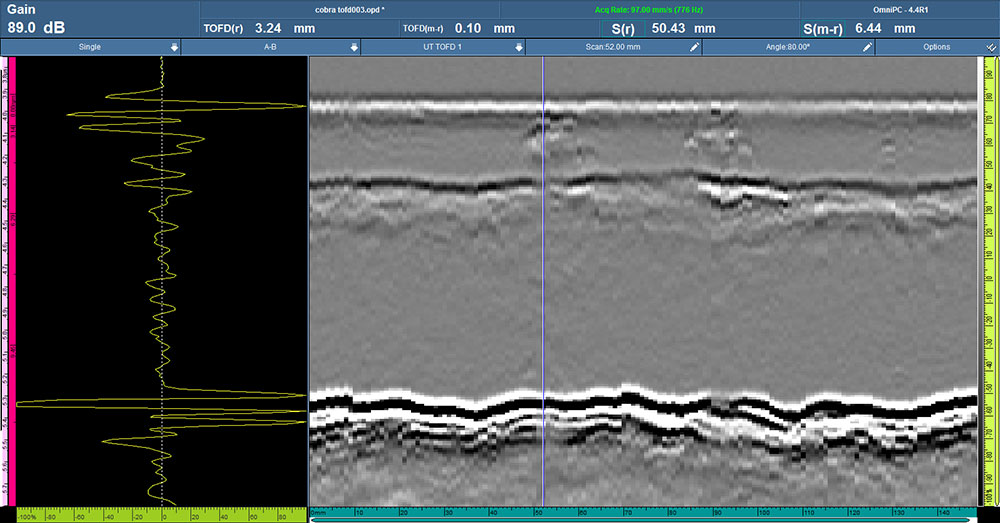

Scan of a weld with the cursor positioned on a discontinuity; the A-scan shows a signal between the lateral wave and the back wall.

|

Equipment Used

- OmniScan® MX2/SX flaw detector

- COBRA solution kit (U8750053, COBRA scanner for pipe inspection (probes and wedges are not included))

- 15 MHz TOFD transducer

- ST1 -80L wedge kit for the COBRA scanner, 1.05 in. to 4.5 in. OD pipes (COBRA-A-ST1-80L, U8710172)

- WTR-SPRAYER-4L or other suitable couplant delivery (U8775153)

- OmniPC™/NDT SetupBuilder/TomoView™ software (optional scan plan and analysis software programs)

Conclusion

The COBRA scanner with TOFD technology provides a cost-effective, efficient, and reliable testing method capable of meeting the challenges associated with inspecting small diameter tubes and pipes. When paired with the OmniScan SX UT flaw detector, the end result is a comprehensive record of inspection data conveniently stored in an electronic format that can be re-opened and analyzed at any time. The evolution of the discontinuities encountered during an inspection can be monitored over time, enabling inspectors to determine a trend and plan for preventive maintenance.

Although radiography is the most commonly used technique for this application, the ultrasound techniques discussed here offer many advantages in terms of safety, the probability of detection, and the speed of inspection.

Summary of key benefits

- Cost-effective weld inspection alternative.

- Precision sizing and measurement.

- When combined with the OmniScan flaw detector, meets code requirements for encoding and full data collection.

- Covers standard pipes ranging from 1.05 in. to 4.5 in. OD.

- Operates in limited access areas.

- Can record the position of the probe at all times to measure the length of discontinuities.

- Precise 32 steps/mm encoder.

- Provides steady and repeatable results.

- Lightweight and easy to install for fast configuration from one weld to the next.

- Waterproof, rust-free, and CE-compliant.