This application note explains how to measure the base curve and thickness of soft contact lenses. Learn about the recommended equipment, measurement methods, and calibration for optimal accuracy.

Ultrasonic Testing of Soft Contact Lenses

In the 1970s, we pioneered the adaptation of ultrasonic thickness gauges for testing soft contact lenses. With ultrasonic gauges it is possible to measure the sagittal height of soft contact lenses for base curve calculation and the lens thickness, without the errors that can be introduced by physical distortion of the lens when using other techniques.

Ultrasonic measurement is fast, repeatable, and reliable, and it is not subject to operator interpretation. The 39DL PLUS™ ultrasonic thickness gauge with Multilayer software incorporates special functions for simultaneous measurement of sagittal height and thickness, combined with calculation of the base curve.

Equipment Used to Measure the Contact Lens Thickness and Base Curve

Gauge: 39DL PLUS gauge with the Multilayer software option

Transducer: M316-SU F-.75 (20 MHz, 0.125 in. element diameter)

Fixture: B-200 contact lens fixture or equivalent

Note: It is also possible to use the 45MG gauge with Single Element software to measure the sagittal height or lens thickness. However, this instrument makes only one type of measurement at a time and does not automatically calculate the base curve.

Measurement Method for the Contact Lens Thickness and Base Curve

The B-200 contact lens holding fixture is a small plastic tank containing a tubular pedestal that has an accurately known diameter. The ultrasonic transducer is held in the base of the fixture, aiming a focused sound beam through the center of the pedestal. A very thin plastic membrane is stretched across the top of the pedestal, and the tank is filled with saline solution. The contact lens is placed on top of the pedestal, concave side down. The plastic membrane then becomes the reference chord for the sagittal height measurement.

In the measurement process, the transducer generates a short pulse of sharply focused ultrasonic energy that travels up through the saline solution. Portions of this energy reflect back to the transducer from the membrane, the bottom surface of the lens, the top surface of the lens, and finally from the surface of the saline solution. The gauge digitally records this pattern of echoes, and then precisely measures the time intervals between the first and second echoes, and between the second and third. The fourth echo, from the surface of the saline solution, is not relevant to this test.

The time interval between the first and second echoes is proportional to the distance between the membrane and the bottom of the lens, or the sagittal height. Similarly, the time interval between the second and third echoes is proportional to the thickness of the lens. The gauge applies the following formula:

D = VT / 2

where

D = distance or thickness

V = velocity of sound waves in the test material

T = measured round trip pulse transit time

Using sound velocity information that has been programmed into the gauge, this simple calculation provides the sagittal height and lens thickness information. The gauge calculates the base curve radius from the following formula:

| H2 + r2 | |

| R = | ------------ |

| 2H |

where

R = base curve radius

H = measured sagittal height

r = radius of pedestal

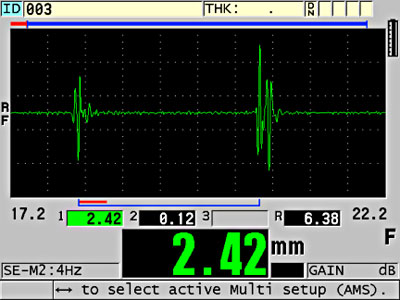

The gauge then displays sagittal height (1), lens thickness (2), and base curve information (R) as shown below:

Sagittal height, lens thickness, and base curve display

Calibrating Your Gauge for Contact Lens Thickness Measurement

The accuracy of any ultrasonic measurement is only as good as instrument calibration. In the case of contact lens measurements, this means accurate calibration of the sound velocity for the saline solution being used, and for the specific lens material. Note that sound velocity in the saline solution will change significantly with temperature and salt concentration, and that lens velocity will also change somewhat with temperature and composition.

The recommended procedure for optimal accuracy is to set up the instrument with the aid of reference standards whose base curve/sagittal height and thickness are precisely known, while maintaining constant temperature. The general procedure for velocity calibration is described in detail in the 39DL PLUS operating manual. With proper instrument setup, sagittal height and thickness may be measured to an accuracy of +/- 0.01 mm.